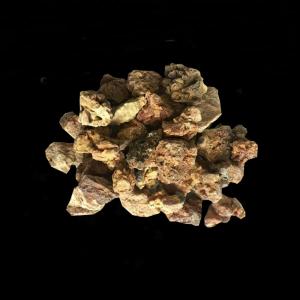

Electrofused Magnesite Electro-fused Magnesite FM

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Quick Details

Place of Origin: Liaoning, China

Application: Refractory

Shape: Block

Material: Magnesite

Chemical Composition: Mgo;CaO;SiO2

Mgo:96%-97%

Product name: FM

Payments terms: 1. 100% L/C at sight 2. 30% T/T prepayment, balance against BL copy

Delivery Time: Within 30 days after receiving L/C or 30% T/T prepayment

Usage: Metallurgy, Foundry, Abrasive, Refractory, Deoxidizer

Advantage: Timely Shipment, High quality, Good performance

Packing: 1mt/bag or as customers' requirements

Size: 0-30mm etc

Sample supply: free sample

Color: Brown, white

MOQ: 25Mt

Supply Ability

Supply Ability:1000 Metric Ton/Metric Tons per Month

Grade | MgO | SiO2 | CaO | Fe2O3 | Al2O3 | Loi | B.D g/cm3 |

Dicalcium-fused magnesium | 97.00 | 0.70 | 1.40 | 0.60 | 0.20 | 0.10 | 3.30-3.36 |

96.50 | 0.85 | 1.60 | 0.70 | 0.20 | 0.15 | 3.20-3.30 | |

96.00 | 0.95 | 1.90 | 0.80 | 0.23 | 0.12 | 3.20-3.30 | |

Common fused magnesite | 97.20 | 0.80 | 1.10 | 0.60 | 0.20 | 0.10 | 3.30-3.36 |

96.50 | 1.20 | 1.30 | 0.70 | 0.20 | 0.10 | 3.20-3.30 | |

96.00 | 1.40 | 1.50 | 0.80 | 0.20 | 0.10 | 3.20-3.30 | |

Size | 0-1mm, 0-30mm, 1-15mm, 1-30mm, 200mesh or according to customer's requirements. | ||||||

Plant photos:

Packaging & Delivery

Packaging Details1MT/bag or as customers' requirements.

Port Main port of China

Loading:

What is fused magnesite?

Fused magnesite is produced by high quality magnesite through electro- fusing, After melting, the SiO2 of material moves to the surface for the difference in the specific, so it has well grown crystals, well crystal perfection and structure homogeneity, excellent chemical stability, good corrosion resistance to slag and high strength at high temperature.

Where to apply fused magnesite?

It is widely used for gunning materials, fused magnesite ramming material, magnesite brick, magnesite chrome brick, vacuum and vacuum induction furnace, electric arc furnace refractory lining, magnesia crucible, furnace and a variety of refractory, such as large scale glass furnace by floating method, electrical furnace, convert furnace, house hold electrical appliances as electrical insulating materials,

- Q: what's the application of fireproofing abs materials?

- a kind of ABS alloy shell, a toy of child, low load bearing, refrigerator lining, it can be processed into various wear-resisting sheets, plates,and has good electrical performance, it can be used as electronic components or auto parts, all kinds of insulation materials, it's easy to machining on the surface, so it can be made into designated special products (such as electroplate), and easy coloring, it can be processed into colorful products, also can be used as a fireproofing electrical appliance outer covering, adding alloy to it will improve its comprehensive performance, etc

- Q: What are the fire endurance requirements of class A fire resistant door ?

- Fire endurance of class A fire resistant door is 1.5h. According to the latest fire door requirements, in FMA FMB FMC three forms, A, B and C represent categories, such as FMA on behalf of Class A fire doors (ie thermal insulation fireproof door). Fire endurances of class A,B and C fire doors are 0.5 1.0 1.5 2.0 3.0. Therefore, the fire resistance of fire door needs to be designed and the design paper will make it clear in general.

- Q: How long is the duration of fire resistance of autoclaved flyash-lime bricks?

- How long is the duration of fire resistance of autoclaved flyash-lime bricks?

- Q: What are the applications of refractory busway?

- Refractory busway is designed for the power supply in fire-fighting equipment, and it can not be used for other purposes. As the generatrix has good heat resistance, thermal insulation, and the heat of the busway can not be emitted, it can not be used long-term at full capacity. In addition to fire-resistant busway, other bus lines can be operated long-term at full load.

- Q: What's the maximum temperature that the refractory ceramic fiber cloth can endure?

- Ceramic fiber cloth is high temperature resistant and its continous use temperature can be up to 1000℃. It has high temperature resistance, low heat conductivity, thermal shock resistance, low thermal capacity; superior insulating property at high temperature, long service life; resistance to nonferrous metals like molten aluminum and zinc erosion; low and high temperature strength; innocuity with no adverse effect on the environment; and it is easy to install.

- Q: How to make use of waste refractory materials whose main elements are alumina and mullite?

- Crushing and pressing refractory bricks, or refractory parts . Such as welding positioner tracks use disposable tools.

- Q: what is the Specifications Grading for Fireproof rubber insulation materials ?

- At present, China Building Materials has two grading criteria for combustion performance. "Combustion Performance Classification Method of Building Materials" and "Combustion Performance Classification Method of Building Materials and Products" (GB8624-2006). Among them, one of the major changes of GB8624-2006 and GB8624-1997 is to divide the material combustion performance grading from homogenous material)Class A (composite sandwich material), B1, B2 and B3 level five minutes as A1, A2, B, C, D, E, F seven levels.

- Q: What is the fireproofing requirements of external wall thermal insulation materials?

- External wall thermal insulation materials fire rating regulations, 1, the height of a building is greater than or equal to 100m , the combustion performance of insulation materials should be level A; 2, the height of a building is greater than or equal to 60m but less than 100m, the combustion performance of insulation materials should not be less than the level B2. When using level B2 thermal insulation material, every layer should set horizontal fire barrier zone 3,The height of building is be equal or greater than 24m but less than 60m, the combustion performance of thermal insulation material should not be less than the level B2. When using level B2 insulation material, each two-layer should set fire barrier zone ; 4, the height of building is less than 24m, the combustion performance of insulation materials should not be less than the level B2. Besides, when using level B2 thermal insulation material, each three-layer should set a horizontal fire barrier zone.

- Q: who knows the technology of fireproofing material?

- 1, Foam insulation board,it's the foam insulation board material made by inorganic ceramic material through high temperature roasting, and is called for short as ceramic insulation plate. 2, composite cement foaming insulation board is made by cement,fly-ash,silica fume and other main materials and it's a kind of hole-closed?lightweight hydrophobic insulation board made by the technologies of foam,maintenance,cutting processing. 3, gypsum foam thermal insulation board is inorganic thermal insulation board that takes industrial by-product gypsum as the main raw material, modify the gypsum through physic modified principle, then foam, casting and cutting through chemical foam principle. 4, aerated concrete panel is made by lightweight material,silicious material, foaming?agent and other raw materials and it's a kind of lightweight concrete plate material made by the high pressure steam of manufacturing technique. 5, rock wool board is made by natural igneous rock and other main materials, and it's a kind of plate with thermosetting resin as binder made through melting in high temperature and centrifugation.

- Q: Are the rubber insulation materials are refractory materials?

- No

Send your message to us

Electrofused Magnesite Electro-fused Magnesite FM

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords