JIS G3303, Prtined Tinplate, Food Package, Gold Oil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Usage

Tinplate is widely used for making all types of containers, containing industrial usage such as paint can, oil can, aerosol cans etc., and food cans like milk powder cans, tomato paste can, dry food cans etc.

2. Quality

As a state owned company and a large tinplate supplier in China, our tinplate quality ranks 1st level in China, similar to Bao Steel, Posco etc.

3. Specification

standard: GB/T2520, JIS G3303, DIN EN10202

Material: MR /SPCC

Thickness available: 0.16-0.50MM

Width available: 600~1050MM

Temper grade: T1 – DR8

Tin coating: ordinary 2.8g/2.8g, 5.6g/5.6g and others

Package: sea worthy export package.

Applications: Tin can for chemicals & paint cans, industrial cans, food cans

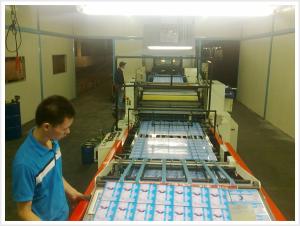

4. Our factory photo & equipments

5. Our Markets:

now our tinplate has been sold to more than 50 countries, including Europe country, Gulf Area, South American, South Afric etc.

6. Our Overseas Wareouses:

Furthermore, in the year 2014, we have more than 10 overseas warehouses all over the word, located in KSA, UAE, Oman, Russia, Kuwait, Qatar, Oman, Chile, Brazil etc.

7. FAQ

a. what's the annual output?

about 500,000 tons per year.

b. where's the raw matrial from?

our hot rolled coil is purchased from Capital Steel and other state owned mill, with quite good quality.

c. how long is the delivery time?

normally for SPCC about 45~55 days, while 65~75 days for MR material

d. how to control the quality during production process?

inside our workshop, we have MES syestem. It realizes the optimization of the production procedure in the workshop. It could record each step of the whole production procedures, and if some problem appears, factory could easily found and take action, it’s quite helpful to monitor and control the quality.

- Q: What are the common defects found in tinplate packaging?

- Common defects found in tinplate packaging include: 1. Corrosion: Tinplate can be prone to corrosion, resulting in rust spots or holes in the packaging. This can compromise the integrity of the packaging and affect the quality and safety of the product inside. 2. Dents and scratches: During handling or transportation, tinplate packaging can get dented or scratched. These defects can be purely cosmetic, but in some cases, they may lead to leaks or damage to the product. 3. Poor sealing: Improper sealing of tinplate packaging can lead to leaks or contamination of the product. This can occur due to faulty machinery or inadequate quality control during the packaging process. 4. Print defects: Tinplate packaging often includes printed information or branding. Common defects in this area include misalignment, smudging, fading, or incomplete printing. These defects can affect the visual appeal of the packaging and the overall product presentation. 5. Manufacturing defects: Tinplate packaging can sometimes have manufacturing defects such as uneven edges, poor welds, or misaligned seams. These defects may weaken the packaging structure or cause sharp edges that could potentially harm consumers. It is important for manufacturers to have strict quality control measures in place to identify and rectify these defects, ensuring the safety, functionality, and aesthetics of tinplate packaging.

- Q: What are the common opening mechanisms for tinplate containers?

- The common opening mechanisms for tinplate containers include pull-tab lids, twist-off caps, and lever lids.

- Q: Can tinplate be used for toys and games?

- Yes, tinplate can be used for toys and games. Tinplate is a lightweight and durable material that can be easily shaped and decorated. It is commonly used to make toy cars, trains, tin soldiers, and various other playthings.

- Q: Can tinplate be used for packaging household products?

- Yes, tinplate can be used for packaging household products. Tinplate is a type of steel coated with a thin layer of tin, which provides excellent protection against moisture, corrosion, and tampering. It is commonly used for packaging food, beverages, and other household products due to its durability, recyclability, and ability to maintain product freshness.

- Q: How does tinplate packaging contribute to product shelf life?

- Tinplate packaging contributes to product shelf life by providing a protective barrier against moisture, light, and oxygen, which helps to prevent spoilage, oxidation, and degradation of the product. This type of packaging also enhances product stability, preserves freshness, and extends the overall shelf life, ensuring that the product maintains its quality and integrity for a longer period of time.

- Q: What are the common sizes of tinplate sheets?

- The common sizes of tinplate sheets vary, but some standard sizes include 4x8 feet, 4x10 feet, and 5x10 feet. However, tinplate sheets can also be custom-cut to specific dimensions as per the requirements of the project.

- Q: How to quickly open the bottle?

- A tin can be opened, the handle is separated, and the canned fruit can be clamped by the head, and the rotating knob and the tin can be opened. Remember, when you turn the knob, you can only rotate clockwise and turn counterclockwise clockwise.

- Q: Can tinplate be used for industrial containers?

- Yes, tinplate can be used for industrial containers. Tinplate is a type of steel sheet coated with a thin layer of tin, which provides corrosion resistance and durability. It is commonly used for manufacturing various types of containers, including those used in the food and beverage industry, aerosol cans, and paint cans.

- Q: How does tinplate affect the overall cost of packaging?

- Tinplate can impact the overall cost of packaging due to its higher production and material costs compared to other packaging materials. However, it offers several advantages such as durability, protection against moisture and oxygen, and aesthetic appeal, which may justify the additional expenses for certain products.

- Q: How is tinplate tested for quality and performance?

- Tinplate is tested for quality and performance through various methods such as visual inspection, chemical analysis, mechanical testing, and corrosion resistance assessment. Visual inspection ensures that the tinplate is free from any surface defects, such as scratches or dents. Chemical analysis verifies the composition of the tinplate, ensuring it meets the required standards. Mechanical testing assesses the strength, ductility, and formability of the tinplate, ensuring it can withstand the intended applications. Lastly, corrosion resistance assessment evaluates the tinplate's ability to resist rust and corrosion, ensuring it maintains its quality over time.

Send your message to us

JIS G3303, Prtined Tinplate, Food Package, Gold Oil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords