Electric Tinplate coil and sheet for sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40900 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

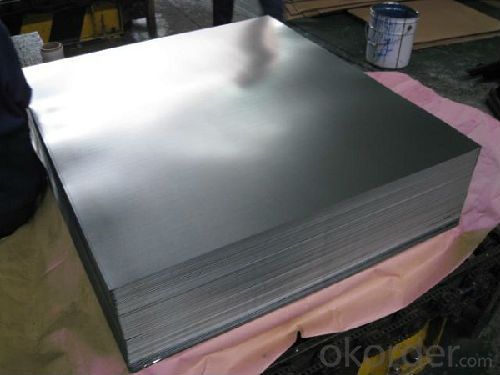

Prime Quality Tinplate Sheets Details

1.Structure of Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc. For caps, there are some customers also need TFS, if you have some demand for TFS,also can contact with us.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Minumum Order Quantity: 25 MT Loading Port:China Main Port

Annual Capacity: 400,000MT Payment Terms:TT or LC

Product Specifications:

Prime Quality Tinplate Sheets Usage and Applications

Prime Quality Tinplate Sheets Specifications

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.18

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

Applications

Chemicals and painting cans

Dry food cans, such as fancy cans, biscuit cans, milk power cans, tea cans

Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

Sea food cans

Crown corks, easy open ends(EOE)

Electrical machinery parts

Bakeware and household kitchen parts

FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

- Q: What are some common tinplate products?

- Some common tinplate products include food and beverage cans, aerosol cans, paint cans, metal packaging for cosmetics and personal care products, and metal containers for various industrial applications.

- Q: Can tinplate be used for furniture applications?

- Yes, tinplate can be used for furniture applications. Tinplate is a versatile material known for its strength and durability, making it suitable for various purposes including furniture. It can be used for making components, frames, or decorative elements in furniture designs. Additionally, tinplate is corrosion-resistant and can be easily shaped, allowing for creative and long-lasting furniture pieces.

- Q: How can tinplate be identified?

- If the food is ready to eat food grade, dressed in non food is to chemical grade on it.

- Q: What is the shelf life of tinplate?

- The shelf life of tinplate can vary depending on various factors such as storage conditions, coating quality, and exposure to external elements. However, under ideal conditions, tinplate can have a shelf life of several years or even decades, as its corrosion-resistant properties help to maintain the integrity of the packaging material and protect the contents stored within.

- Q: Can tinplate be used for pharmaceutical blister packaging?

- Yes, tinplate can be used for pharmaceutical blister packaging.

- Q: What are the advantages of using tinplate for furniture?

- One advantage of using tinplate for furniture is its durability. Tinplate is known for its strength and resistance to corrosion, making it a long-lasting material for furniture. Additionally, tinplate is also lightweight, making it easy to move and rearrange furniture as needed. Moreover, tinplate can be easily molded into various shapes and designs, allowing for versatile and customizable furniture options. Lastly, tinplate is a cost-effective choice, as it is typically less expensive than other materials commonly used for furniture production.

- Q: How does tinplate impact the overall product safety?

- Tinplate is known for its excellent barrier properties, durability, and resistance to corrosion, making it a popular choice for packaging food and beverages. Its impact on overall product safety is significant as it helps to prevent contamination, preserve product freshness, and extend shelf life. Tinplate acts as a protective barrier between the product and external factors such as light, air, moisture, and bacteria, ensuring that the contents remain safe and uncontaminated. Additionally, tinplate is non-toxic, making it a safe material for packaging edible goods. Overall, tinplate positively contributes to product safety by providing a reliable and secure packaging solution.

- Q: What are the advantages of using tinplate for HVAC components?

- There are several advantages of using tinplate for HVAC components. Firstly, tinplate offers excellent corrosion resistance, ensuring durability and longevity of the components even in harsh environmental conditions. Secondly, tinplate is lightweight yet strong, making it easier to handle and install. Additionally, it provides good heat conductivity, allowing for efficient heat transfer in HVAC systems. Lastly, tinplate is cost-effective and readily available, making it a cost-efficient choice for manufacturing HVAC components.

- Q: How does tinplate compare to aluminum packaging?

- Tinplate and aluminum packaging have their own unique advantages and characteristics. Tinplate offers excellent resistance to corrosion, making it ideal for preserving food and beverages. It is also known for its durability and ability to withstand high temperatures. On the other hand, aluminum packaging is lightweight, malleable, and provides a strong barrier against light, oxygen, and moisture. It is widely used in the beverage industry due to its recyclability and sustainability. Ultimately, the choice between tinplate and aluminum packaging depends on specific requirements such as product compatibility, cost, environmental impact, and desired aesthetics.

- Q: What is the thickness range of tinplate?

- The thickness range of tinplate typically varies between 0.13mm to 0.49mm.

Send your message to us

Electric Tinplate coil and sheet for sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40900 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords