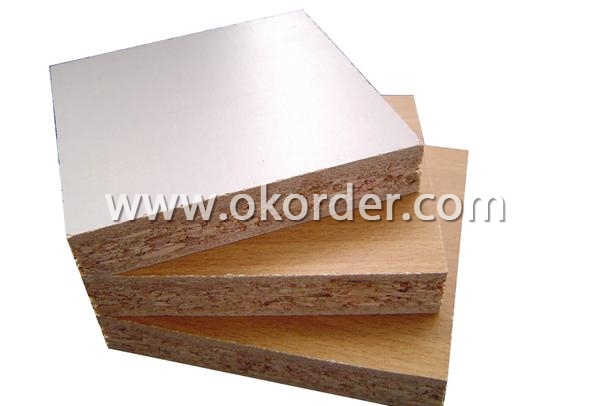

E1 Melamine Faced Particle Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 CBM m³

- Supply Capability:

- 50000 CBM per year m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

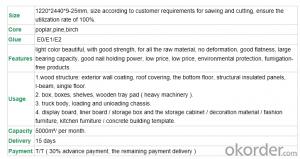

1.Basic Specificaiton of Melamin Faced Partical Board

|

Plain / Poplar Particle board | |

|

Size |

1220*2440; |

|

Thickness |

2.5mm,5mm,6mm,8.0mm,9.0mm,12mm,14mm,15mm,16mm,18mm,22mm,25mm or as your request |

|

Material |

Poplar or pine |

|

Surface |

Melamine(Solid color or woodgrain),veneer,PVC |

|

Color |

Any color |

|

Glue |

E0,E1,E2,MR |

|

MOQ |

21cbm |

|

Density |

650-700kg/m3 |

|

expansion rate : |

8%-10% |

|

Features |

moisture-proof,good nailing strength,suitable for wardrobe making |

2. Products Charateristics

(1)Density:tolerance+/-2%

(2)Moisture-proff,low formaldehyde emissions,fast curing ,high tack

(3)mixed hardwood,poplar,pine or Eucalytus

(4)Good for different climatic conditions

(5)Function:making furniture,doors and windows and floor and kitchen cabinet,e.g.

(6)we have about more than 200 colors for your choice

3. Look forward to your inquiry.

We persevere in the management of credit and innovation,and we are

willing to cooperate with all the friends for mutual development. looking

forward to your inquiry and trail order.

- Q: What are the raw materials for making the particleboard?

- The former fat color is light, the curing temperature is low, all kinds of plant raw materials such as wheat straw, rice husk and so on have good glue effect, hot pressing temperature is 195 ~ 210 ℃.

- Q: Particleboard industry is currently looking ahead

- Seeking resource-rich and inexpensive adhesives is an important factor in the development of particleboard production

- Q: Make the raw material of the particleboard

- The compound is ejected from the nozzle to form particles of 8 to 35 microns in diameter, forming an extremely thin and uniform continuous layer on the surface of the shavings

- Q: Particleboard in the production process of environmental performance

- if the smell is large or have tears, indicating that the release of formaldehyde in the particleboard may be higher.

- Q: Raw materials for the production of particleboard include

- Therefore, the use of dryers on the initial moisture content of different shavings to dry, so that it reaches a uniform final moisture content

- Q: Particleboard production process requires proper hot pressing pressure

- Box molding method is a special press pressure, a pressure made of products for the manufacture of crates.

- Q: From the appearance point of view

- the length is generally 5-10MM length is appropriate, too long structure loose, too short anti-deformation of the poor, the so-called static bending strength is not compliance;

- Q: Market foreground and Industry development

- the quality of China's particleboard has been significantly improved, and re-accepted by the market,

- Q: Production of raw materials for particleboard

- Wood raw materials are taken from the forest cuttings, small diameter timber (usually less than 8 cm in diameter), harvesting residues and wood processing residues

- Q: What are the disadvantages of particleboard?

- in the cutting board is likely to cause the phenomenon of violence teeth, so part of the process requirements for processing equipment higher; not on-site production;

Send your message to us

E1 Melamine Faced Particle Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 CBM m³

- Supply Capability:

- 50000 CBM per year m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords