Strong Adhesive Double-Sided Fiberglass Mesh Tape for Buildings and Wall Marble Net

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

E-glass Fiberglass Mesh Marble Net for Buildings

Definition of E-glass Fiberglass Fabric Mesh

E-glass Fiberglass Mesh Marble Net is mainly alkali-resistant fiberglass fabric. Fiberglass Mesh mainly use the C /E-glass fiber yarn (main ingredient is a silicate, good chemical stability) through a special weaving technique, then by the anti-alkali and reinforcing agent etc high temperature heat finishing treatments. Fiberglass Mesh is an ideal engineering material in construction and decoration industry.

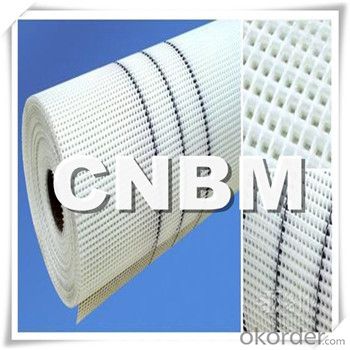

Image of E-glass Fiberglass Mesh Marble Net

Application/Usage of E-glass Fiberglass Mesh Marble Net

External thermo insulating composite System (ETICS) & External insulating finish system (EIFS)

External and internal plaster reinforcement Fiberglass Mesh, Electrical heating mats Fiberglass Mesh

Marble slab reinforcement / Mosaic carrier Fiberglass Mesh, Asphalt reinforcement (roof water-proof) Reinforced lightweight construction boards Fiberglass Mesh.

E-glass Fiberglass Mesh Marble Net Production Process

Application :

Package: E-glass Fiberglass Fabric Mesh are packed in shrink-wrapped, then put into cartons or pallets.

Packing volumes: about 20000m/20FCP, 40000m2/40HQ.

Delivery: About 15 days after confirming the order.

FAD:

Q: What is the storage of Fiberglass Mesh?

Store Fiberglass Mesh out of direct sunlight, away from direct contact ground or concrete;

Store Fiberglass Mesh rolls in cool, dry location, away from weather or other damage.

Q: What is the guarantee period of Fiberglass Mesh ?

Fiberglass Mesh: Four years under normal weather conditions and usage directions.

Q: What is the Advantage of Fiberglass Mesh ?

Good chemical stability: Alkali-resistant, acid-resistant, waterproof, cement erosion-resistant, and other chemicals' corrosion resistant; and strong resin bonding, soluble in styrene.

Outstanding craftsmanship include coating enough alkali-resist glue, our coating glue is produced by Germany BASF which can keep 60-80% strength after test in Naoh 28days later, so that guarantee high strength, high tensility, light weight.

Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it's 20% extra strong strength and beauty surface than normal fiberglass yarn.

Strength retention rate> 90%, elongation<1%, the durability of more than 50 years.

Good dimensional stability & positioning property, stiffness, smoothness an difficult to shrink & deformation.

Good impact resistance and not easy to be teared.

Q: Why choose our CNBM Fiberglass Mesh?

We are the manufacturer of Fiberglass Mesh, price will be reasonable and much competitive

We have produced Fiberglass Mesh strictly in according to customers' detailed requirements

CNBM Fiberglass Mesh theme is: Good Quality, High Credibility & Best Service.

- Q: Dust screen can really dust-proof? Dust screen window shopping tips

- Look.Jacobs is divided into domestic and imported, generally speaking, the first one is composed of chemical fiber, then one is made of glass fiber, is also part of the plastic material, in the selection, try to use imported gauze, because it can be tens of thousands of times through the sliding friction and deformation, should also see its yarn the hole is uniform, or touch Jacobs, the feel is slightly scraping.

- Q: The difference between glass fiber and plastic fiber screen

- Bacteria are generally not electrostatic adsorption, so the chemical fiber screen is difficult to obstruct bacteria!!! In addition, according to the test, the dust holding capacity of the glass fiber filter is much larger than that of the chemical fiber! And efficiency will not go down! As for the cost... Now it's about the same! As for the wind resistance, fiberglass is several times the chemical fiber

- Q: How to use gridding cloth tape, namely glass fiber self adhesive tape?

- Use it with the case sealing tape.

- Q: Is the inner wall plastering glass fiber net strong?

- Surface mortar for plastering engineering refers to smear on the surface of the substrate material, has a protective base and increase the aesthetic effects, process system construction to provide special functions for buildings.

- Q: Eradication of old wallpaper paste mesh ceiling if it will not crack?

- Not necessarily, the longer the time , the easier appearance of the cracking.

- Q: The decoration of an old house whose walls of the bedroom and living room have many cracks. Now it is intended to shovel out the wall surface before putting them on the wall mesh. Can this prevent further cracking in the future?

- After a long time, it will still cracking.

- Q: What are the types of mesh?

- 1000mm Length: 600mm: White (standard). Mesh Size: 50m: Interior wall insulation fiberglass mesh: According to customers' requirements

- Q: Why is it required to wrap alkali-resistant fiberglass mesh at the entrance to the hole?

- Flanging is good for protecting the edge of insulating layer and door and window are vulnerable to external damage. The window and door openings and other locations are not the continuation of the mesh position, large wall decapitated need Internet Plaid lap, discrete locations Mesh prone to stress concentration cracks,

- Q: What is the difference in function between alkali-resistant fiberglass mesh and hot dipping galvanized steel mesh?

- They transfer the surface load acting body. When the basis weight of fiberglass mesh increases,you must strictly control the quality of hot dipping galvanized steel to meet the stability of insulation system; the greater tensile bonding strength of brick not only protects the thermal insulation layer, but also the failure surface after drawing is concentrated on the fiberglass mesh, while having good construction operability.

- Q: How to use resin and good glass fiber gridding cloth?

- The viscosity of the resin should be moderate; The surface modifying agent of the glass fiber cloth and the compatibility of resin should be better; Resin solution mixing should be sufficient to ensure uniform distribution of resin solution; The temperature should be moderate (too high temperature will let resin curing ahead of time and too low molecular inadequate activity); The pressure should be moderate (so as to exhaust air from the glass fiber cloth while not damaging the glass cloth). It mainly is about the above points.

Send your message to us

Strong Adhesive Double-Sided Fiberglass Mesh Tape for Buildings and Wall Marble Net

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords