Fiberglass Mat Tissue - E-Glass Fiberglass Mat, Powder, 1040mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

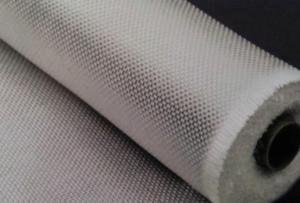

Structure of Chopped strand mat

Chopped strand mat is made from fiberglass chopped strands boned with powder binder or emulsion binder.

E glass chopped strand mat is made from fiberglass strands chopped to length and bonded together

with powder binder. Chopped strand mat is used primarily for hand lay-up processes, filament winding and press molding of FRP products. Typical products include bathroom

accessories, pipe, building materials, automobiles, furniture and other FRP products.

This products ischaracterized bg good combination of resin,easg operation ,good wet strengthretention,good laminate transparency

E glass chopped strand mat is made from fiberglass strands chopped to length and bonded together

with powder binder. Chopped strand mat is used primarily for hand lay-up processes, filament winding and press molding of FRP products. Typical products include bathroom

accessories, pipe, building materials, automobiles, furniture and other FRP products.

Images

Features of E-glass Chopped Strand Mat

1.Consistent thickness and stiffness;

2.Rapid impregnating and good compatibility with resin;

3.Superior wet through with less air trap;

4.Good mechanical properties and high strength of parts

FAQ of Chopped strand mat

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

- Q: Can fiberglass mat tissue be used for corrosion-resistant applications?

- Corrosion-resistant applications can indeed utilize fiberglass mat tissue. Comprised of delicate glass fibers fused with a resinous binder, this tissue offers exceptional properties for combating corrosion. Specifically designed to serve as a barrier layer, it finds utility in a range of applications that require resistance to corrosion, such as the construction of tanks, pipes, and vessels that face exposure to corrosive environments. By acting as a protective barrier, the fiberglass mat tissue effectively thwarts the infiltration of corrosive elements, thereby significantly enhancing the structure's longevity and durability. Furthermore, its lightweight nature and ease of handling, coupled with its ability to be easily molded into intricate shapes, render it an exemplary choice for corrosion-resistant applications.

- Q: Does fiberglass mat tissue require any special precautions during storage?

- Yes, fiberglass mat tissue does require special precautions during storage. It should be stored in a dry and well-ventilated area to prevent moisture damage. Additionally, it should be kept away from direct sunlight and extreme temperatures as they can degrade the material. Proper stacking and support should also be ensured to prevent any deformation or damage.

- Q: What is the moisture resistance of fiberglass mat tissue?

- The moisture resistance of fiberglass mat tissue is high.

- Q: Can fiberglass mat tissue be used for bridge construction?

- Yes, fiberglass mat tissue can be used for bridge construction. It is often used as a reinforcement material in the construction of bridges due to its high strength, durability, and resistance to corrosion. It helps to improve the overall structural integrity and longevity of the bridge.

- Q: Is fiberglass mat tissue suitable for insulation in laboratories?

- Fiberglass mat tissue is indeed suitable for insulation in laboratories. It is a commonly used material for thermal insulation due to its excellent thermal properties. Fiberglass mat tissue has a high resistance to heat transfer, making it an effective insulator to maintain stable temperatures within laboratory spaces. Additionally, fiberglass mat tissue is also resistant to moisture, chemicals, and fire, which are crucial factors in laboratory settings. It can withstand exposure to harsh chemicals and does not degrade or lose its insulating properties over time. This makes it ideal for insulation in laboratories where various chemicals and substances are handled. Furthermore, fiberglass mat tissue is easy to install and can be customized to fit specific insulation requirements. It can be applied to walls, ceilings, and pipes to create a barrier that prevents the transfer of heat, ensuring a controlled environment within the laboratory. Overall, fiberglass mat tissue is a suitable choice for insulation in laboratories due to its thermal resistance, chemical resistance, fire resistance, and ease of installation. It helps to maintain stable temperatures, protects against chemical exposure, and ensures safety in laboratory environments.

- Q: Does fiberglass mat tissue provide any thermal insulation?

- Yes, fiberglass mat tissue does provide thermal insulation. Fiberglass is a poor conductor of heat, which means it does not transfer heat easily. When used as a mat tissue, it helps to trap air within its fibers, creating a layer of insulation. This insulation layer acts as a barrier, preventing heat transfer through conduction and reducing thermal energy loss. Therefore, fiberglass mat tissue can be an effective solution for providing thermal insulation in various applications, such as construction, automotive, and aerospace industries.

- Q: Can fiberglass mat tissue be used in automotive manufacturing?

- Yes, fiberglass mat tissue can be used in automotive manufacturing. Fiberglass mat tissue is a lightweight, flexible material made from glass fibers that are bonded together with a binder. It is commonly used in the automotive industry for various applications such as reinforcing body panels, creating structural components, and improving sound and heat insulation. One of the main advantages of using fiberglass mat tissue in automotive manufacturing is its high strength-to-weight ratio. It provides excellent reinforcement properties while adding minimal weight to the vehicle, making it an ideal choice for achieving fuel efficiency and reducing emissions. Additionally, fiberglass mat tissue is highly moldable, allowing it to be easily shaped and formed into complex geometries required for automotive parts. This material can be used to reinforce areas that are susceptible to high stress, such as the roof, doors, and undercarriage, thereby enhancing the overall strength and durability of the vehicle. Moreover, fiberglass mat tissue offers excellent resistance to corrosion, chemicals, and extreme temperatures, making it suitable for use in diverse automotive environments. It is also an effective sound and heat insulator, helping to reduce noise and maintain a comfortable interior temperature. Overall, fiberglass mat tissue has proven to be a valuable material in automotive manufacturing due to its lightweight, strong, moldable, and durable properties. Its versatility and performance characteristics make it a preferred choice for many automotive manufacturers looking to enhance the quality and performance of their vehicles.

- Q: Can fiberglass mat tissue be used for insulation in hot climates?

- Yes, fiberglass mat tissue can be used for insulation in hot climates. It has excellent thermal insulation properties and can effectively block heat transfer, making it suitable for use in hot climates to maintain cooler indoor temperatures.

- Q: Can fiberglass mat tissue be used for repairing fiberglass RVs?

- Fiberglass mat tissue is a suitable option for fixing fiberglass RVs. This lightweight and flexible material is commonly employed to strengthen and mend fiberglass structures. Its design allows for easy molding and shaping to conform to the contours of the damaged area, making it an excellent choice for repairing RVs with curved surfaces. To repair a fiberglass RV using fiberglass mat tissue, you must first clean and prepare the damaged area. This involves removing any loose or damaged fiberglass. Next, you cut the mat tissue to the appropriate size and shape, ensuring it covers the damaged area completely. Apply a suitable fiberglass resin or adhesive to both the damaged area and the backside of the mat tissue. Carefully place the tissue over the damaged area, pressing it down firmly to ensure proper adhesion. Once the repair is finished, allow the fiberglass resin or adhesive to cure according to the manufacturer's instructions. After curing, you can sand, prime, and paint the repaired area to match the rest of the RV's exterior. It's crucial to note that fiberglass mat tissue is typically used for smaller repairs and cosmetic damage. For more extensive structural repairs, additional reinforcement materials such as fiberglass cloth or woven roving may be necessary. It is highly recommended to consult a professional or refer to specific repair guides for detailed instructions on repairing fiberglass RVs.

- Q: Is fiberglass mat tissue suitable for insulation in pharmaceutical plants?

- Insulation in pharmaceutical plants cannot be accomplished with fiberglass mat tissue, as it does not meet the necessary criteria. The insulation materials used in pharmaceutical plants must fulfill specific requirements, including being non-porous, non-shedding, and resistant to moisture and chemicals. Unfortunately, fiberglass mat tissue is a porous substance that can shed fibers, posing a risk of contamination to the pharmaceutical production environment. Moreover, it may not offer sufficient protection against moisture and chemicals, both of which are prevalent in pharmaceutical plants. To ensure compliance with the required standards and regulations for insulation in these delicate environments, it is advisable to utilize insulation materials that are explicitly designed and certified for pharmaceutical applications.

Send your message to us

Fiberglass Mat Tissue - E-Glass Fiberglass Mat, Powder, 1040mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords