Fiberglass Yarn for Tissue Manufacturing - e-glass Fiberglass Yarn

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introductions

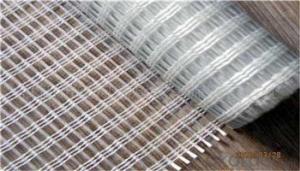

E-Glass Fiber Glass Yarn For Tissue Manufacturing is a kind of additional twisting and plying yam. With the characteristics of high strength, corrosion resistance, heat resistance and high moisture absorption, no-alkali yam has high electric insulation, so it used to produce weaved wires and cables’ wrap cladding, protection sleeve, train of mine, insulation materials of electric machinery, every yam of woven cloth and other industrial yam. It can also supply big and little paper cube and other cube yams with different shapes and different roll weight.

2.Product Features

Good Dispersibility.

Less fuzzy.

Density Even

3.Product Specifications

Product Code | Tex | diameter (um) | Sizing. | breaking strength | Twist |

CC7.5-22-1/2 110S | 44 | 7.5 | paraffin | ≥15.5 | 110±10 |

EC9-33-1/2 65S | 66 | 9 | ≥24.1 | 65±5 | |

EC8-25-1/2 65S | 50 | 8 | ≥19.2 | 65±5 | |

CC9-33-1/2 65S | 33 | 9 | ≥20.6 | 65±5 | |

CC11-44-6/0 | 264 | 11 | ≥81.6 | ||

CC11-44-1/3 110S | 132 | 11 | silane | ≥40.8 | 28±3 |

EC9-68-1/0 28Z | 68 | 9 | ≥18.0 | 28±3 |

4.FAQ

Storage:

Unless otherwise specified,It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

Empty Bobbins Returning:

The bobbins need to be returned and the buyer shall send bobbins to destination port and bear the related charge one they can filled in a full 40HQ.The seller shall handle the sea fright from destination port to China port.Customer should pay some deposite for the empty bobbins and the deposite can be treated as the payment for the future orders after the bobbins are sent back to the seller.

- Q: How does the conductivity of fiberglass yarn compare to other materials?

- The conductivity of fiberglass yarn is significantly lower compared to other materials. Fiberglass is a non-conductive material, meaning it does not allow the flow of electric current through it easily. This is due to the high electrical resistance of fiberglass, which restricts the movement of electrons. In contrast, many other materials such as metals have high conductivity, allowing electric current to pass through them with ease. Metals have free electrons that can move freely, facilitating the flow of electricity. This is why metals are commonly used in electrical wiring and other applications that require good conductivity. The low conductivity of fiberglass yarn makes it suitable for various applications where electrical insulation is needed. It is often used in the manufacture of electrical insulating materials, such as insulating tapes, cables, and circuit boards. The non-conductive nature of fiberglass yarn helps to prevent the risk of short circuits and electrical hazards. It is important to note that the conductivity of materials can vary depending on their composition, structure, and other factors. While fiberglass yarn has low conductivity compared to metals, there may be other non-metallic materials that have even lower conductivity than fiberglass. Additionally, there may be specialty materials engineered to have higher conductivity than fiberglass for specific applications. Therefore, it is always recommended to consider the specific requirements of the application when evaluating the conductivity of different materials.

- Q: Is fiberglass yarn resistant to fire or flames?

- Yes, fiberglass yarn is inherently resistant to fire or flames due to its non-combustible nature and high melting point.

- Q: Is fiberglass yarn resistant to rot?

- Yes, fiberglass yarn is resistant to rot. Fiberglass is made from a combination of glass fibers and resin, which makes it highly durable and resistant to moisture, rot, and decay. This characteristic of fiberglass yarn makes it an excellent choice for applications where exposure to moisture or harsh environmental conditions is expected. Additionally, the non-porous nature of fiberglass yarn prevents the growth of mold, mildew, and bacteria, further enhancing its resistance to rot.

- Q: Can fiberglass yarn be used for reinforcement in pipes?

- Yes, fiberglass yarn can be used for reinforcement in pipes. It is commonly used as a strong and durable material to improve the structural integrity of pipes and enhance their resistance to pressure, corrosion, and other external factors.

- Q: How does fiberglass yarn perform in terms of elasticity?

- Compared to other types of yarn, fiberglass yarn is renowned for its low elasticity. This is because it is composed of inorganic materials, including glass fibers, which do not possess the same level of stretchability as natural or synthetic fibers. Consequently, fiberglass yarn is not the ideal choice for garments or fabrics that necessitate flexibility and resilience to conform to body movements. Nevertheless, this characteristic can prove advantageous in specific industries or applications that prioritize stability and rigidity, such as the construction of composite materials or the reinforcement of concrete structures. In such cases, the low elasticity of fiberglass yarn aids in preserving the intended shape and structural integrity.

- Q: Can fiberglass yarn be used in ballistic applications?

- Yes, fiberglass yarn can be used in ballistic applications. Fiberglass yarn is known for its high strength-to-weight ratio, making it an ideal material for applications that require resistance to high impact and penetration, such as ballistic protection. The yarn's inherent properties, such as its high tensile strength and excellent energy absorption capabilities, make it effective in stopping projectiles and reducing their impact. Additionally, fiberglass yarn can be woven or layered into fabrics or composites, providing flexibility in design and enhancing its ballistic properties. Its resistance to heat and chemicals further contribute to its suitability for ballistic applications. Overall, the use of fiberglass yarn in ballistic applications offers enhanced protection and durability.

- Q: Is fiberglass yarn resistant to pilling or fuzzing?

- Fiberglass yarn exhibits exceptional resistance against pilling or fuzzing, unlike natural fibers like cotton or wool. Its composition, derived from synthetic materials, provides remarkable durability and prevents easy breakage or fraying. Consequently, the formation of pills or fuzz on the yarn's surface is highly hindered. Moreover, the sleek and smooth characteristics of fiberglass yarn further discourage the accumulation of loose fibers or lint. Consequently, the original appearance and texture of fiberglass yarn are maintained for extended periods, making it an ideal option for products that demand high resistance to pilling or fuzzing, such as upholstery fabrics, outdoor textiles, or industrial applications.

- Q: Can fiberglass yarn be used in gaskets and seals?

- Yes, fiberglass yarn can be used in gaskets and seals. Fiberglass yarn is a strong and durable material that has excellent resistance to heat, chemicals, and abrasion. These properties make it an ideal choice for applications where gaskets and seals are required to withstand high temperatures, corrosive fluids, and harsh environments. Fiberglass yarn can be woven into fabric or used as a reinforcing material in rubber compounds to enhance the strength and flexibility of gaskets and seals. Additionally, fiberglass yarn can also be impregnated with various resins or coatings to further enhance its sealing properties. Overall, fiberglass yarn is a versatile material that can effectively be used in the manufacturing of gaskets and seals for a wide range of industrial applications.

- Q: Can fiberglass yarn be used for reinforcement in sporting goods?

- Yes, fiberglass yarn can be used for reinforcement in sporting goods. Fiberglass yarn is known for its high strength-to-weight ratio and excellent durability, making it an ideal material for reinforcing various sporting goods such as tennis rackets, hockey sticks, and surfboards. The fiberglass yarn can be woven into a fabric or used as a core material to provide additional strength and stiffness to the sporting equipment. Its properties also make it resistant to moisture and corrosion, ensuring long-lasting performance. Additionally, fiberglass yarn is relatively lightweight, allowing for enhanced maneuverability and improved performance in various sporting activities.

- Q: Is fiberglass yarn suitable for outdoor use?

- Yes, fiberglass yarn is suitable for outdoor use. It is known for its durability, resistance to harsh weather conditions, and ability to withstand UV rays. It is commonly used in outdoor applications such as in the construction of awnings, outdoor furniture, and other outdoor textiles.

Send your message to us

Fiberglass Yarn for Tissue Manufacturing - e-glass Fiberglass Yarn

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords