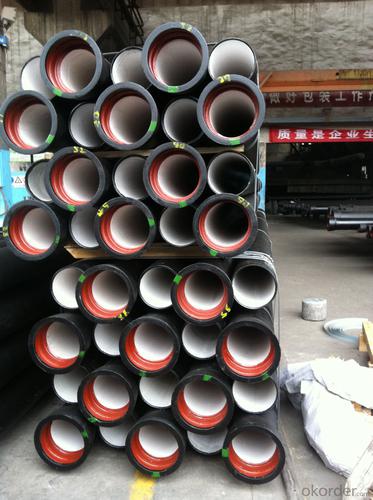

DUCTILE IRON PIPEs K8 CLASS DN1000

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 32 pc

- Supply Capability:

- 3000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

· Material : Ductile Cast Iron

· Size Range : DN 80mm to DN 2000mm

· Unit Effective Length : 6m or 5.7m

· Manufacture Standard: ISO 2531:1998/ EN 545:2006/EN 598:2007

· Annual capacity : 200,000 tons

· Coating Exterior: Zinc 130g/m2 according to ISO 8179-1 and bitumen coating 70 microns.

· Cement Interior: Portland Cement/ High Alumina Cement/ Sulphate Resisting Cement Lining according to ISO 4179

· Special requirements on external coating and internal lining can be applied

· We also provide accessories such as SBR/EPDM rubber gaskets, lubricant paste, pipe caps, PE sleeves, etc.

Additional Parts:

Each pipe is strictly inspected according to related standard to ensure permanently high performance.

Easy Installation at site and service free for life

Long Service Lifespan

Quotation will arrive you within 24hours once we get your inquiry.

We guarantee offering you a competitive price.

A copy of original inspection reports of pipes will be offered after shipment.

Photos of loading process will be sent to the customer after shipment effect.

We will follow-up the delivery progress after shipment effect and update to the customer on weekly basis.

- Q: Fire water supply network adopts ductile iron pipe, the test pressure should be no more than MPa

- Strictly speaking: the outer pipe network and the internal pipe network are the same. Minimum fire 1.0MPa, minimum sprinkler 1.4MPa. Because not only in accordance with the water pump, but also take into account the pressure on the fire engine.

- Q: Are ductile iron pipes suitable for road crossings?

- Indeed, road crossings can indeed be suitably accommodated by ductile iron pipes. Given its robustness and durability, ductile iron proves to be exceedingly appropriate for subterranean installations, specifically road crossings. These pipes exhibit remarkable tensile strength, enabling them to endure substantial loads and traffic pressures without succumbing to fractures or breakages. Moreover, ductile iron pipes showcase exceptional resistance to corrosion, guaranteeing their durability even in the harshest of environments. Not to mention, their effortless installation and upkeep render them a dependable option for road crossings.

- Q: Can ductile iron pipes be used in areas with high levels of hydrogen sulfide gas and corrosion potential?

- Before making a decision, it is important to take certain factors into consideration when considering the use of ductile iron pipes in areas with high levels of hydrogen sulfide gas and corrosion potential. Ductile iron pipes display a strong resistance to corrosion, particularly when they are adequately protected with external coatings and linings. This characteristic makes them appropriate for environments with moderate levels of hydrogen sulfide gas and corrosion potential. Nevertheless, in areas with exceedingly high levels of hydrogen sulfide gas and severe corrosion potential, alternative materials such as corrosion-resistant alloys or specially coated pipes may be more suitable. To determine the suitability of ductile iron pipes, conducting a thorough evaluation of the specific conditions in the area is crucial. Factors such as the concentration of hydrogen sulfide gas, the presence of other corrosive elements or chemicals, and the overall corrosiveness of the environment should be taken into account. Furthermore, consulting the local regulations and industry standards is essential to ensure compliance and safety. In conclusion, while ductile iron pipes can withstand moderate levels of hydrogen sulfide gas and corrosion potential, it is necessary to conduct a comprehensive assessment of the specific conditions. In areas with high levels of hydrogen sulfide gas and severe corrosion potential, consulting with experts in the field and considering alternative materials may be required.

- Q: How are ductile iron pipes protected against internal corrosion caused by chemicals?

- To safeguard against internal corrosion caused by chemicals, ductile iron pipes implement various protective measures. Primarily, these pipes are equipped with either a cement mortar lining or an epoxy coating, creating a barrier between the water or sewage's chemical substances and the iron material. This barrier effectively prevents direct contact, thereby averting corrosion. Additionally, a corrosion-resistant polymer or bituminous coating is frequently applied to the pipes' exterior. This supplementary layer of protection shields the pipes from potential chemical exposure originating externally. Moreover, cathodic protection is a commonly employed technique to counter internal corrosion. Sacrificial anodes, typically composed of zinc or magnesium, are affixed to the pipes. Over time, these anodes undergo corrosion instead of the iron, sacrificing themselves to safeguard the pipes against chemical-induced corrosion. Furthermore, regular maintenance and monitoring play a crucial role in the prevention and rectification of corrosion issues. This entails routine inspections, cleaning, and prompt repair of any corroded or damaged areas. Overall, the integration of lining, external coating, cathodic protection, and maintenance practices ensures the comprehensive protection of ductile iron pipes against internal corrosion caused by chemicals. This prolongs their lifespan and guarantees the integrity of the pipeline system.

- Q: Is nodular cast iron pipe filled with Yau Ma Tei?

- In many areas of our country, ductile iron pipe in the middle and small diameter to tube connected with the tube, the bearing type or flange interface method; ductile iron, angle limit must be allowed better seismic performance and sealing performance.

- Q: Are ductile iron pipes suitable for sewer force mains?

- Sewer force mains can indeed make use of ductile iron pipes. Ductile iron, a variant of cast iron, possesses a higher degree of strength and flexibility in comparison to conventional cast iron pipes. This quality renders it suitable for applications where pipes must endure high pressure and heavy loads, such as sewer force mains. Ductile iron pipes exhibit exceptional resistance against corrosion and boast impressive durability, which proves vital for sewer systems that face exposure to various corrosive substances and challenging environments. Moreover, these pipes possess the ability to absorb vibrations and shocks, thereby reducing the risk of pipe failures caused by external forces. Furthermore, ductile iron pipes possess a renowned reputation for their lengthy service life, frequently extending beyond 100 years. As a result, they constitute a cost-effective choice for sewer force mains, necessitating minimal maintenance and replacement throughout their lifespan. In conclusion, ductile iron pipes offer a dependable and long-lasting solution for sewer force mains, delivering the requisite strength, flexibility, and resistance to corrosion to ensure the efficiency and durability of sewer systems.

- Q: Can ductile iron pipes be used for underground cable conduits?

- Yes, ductile iron pipes can be used for underground cable conduits. Ductile iron pipes are known for their strength, durability, and resistance to corrosion, making them suitable for various applications including underground cable conduits. They have the ability to handle heavy loads and provide protection to the cables from external elements. Additionally, ductile iron pipes have a long lifespan, reducing the need for frequent replacements and maintenance. However, it is important to consider factors such as depth of burial, soil conditions, and specific requirements of the cable installation before choosing ductile iron pipes for underground cable conduits.

- Q: Is there any cast iron pipe used in the fire hose?

- I don't know, I only know that the fire pipes produced by our company is the base tube is a pipe, and then coated with a corrosion and non-toxic, long service life, we are Suzhou Yuyao Pipe Industry Co. Ltd. is a professional production of the manufacturers, oh

- Q: Usage of ductile iron pipe expander

- Ductile iron expansion is mainly provided with large flexible, easy installation, the product main material for nodular cast iron, nodular cast iron is mainly through spheroidization and inoculation by spherical graphite, effectively improve the mechanical properties of cast iron, especially the plasticity and toughness increased, resulting in higher than the strength of carbon steel. The material mainly has high strength of plasticity and toughness, and its development at home and abroad is very fast, the output has exceeded cast steel and malleable cast iron, become second only to gray cast iron casting alloy material. Spheroidal graphite is obtained by spheroidizing and inoculation of nodular cast iron. It can effectively improve the mechanical properties of cast iron, especially improve the plasticity and toughness, so as to obtain higher strength than carbon steel.

- Q: How are ductile iron pipes protected against stray current corrosion?

- Ductile iron pipes are protected against stray current corrosion through the implementation of various measures. One common method is the installation of a protective coating, such as an epoxy or zinc coating, on the external surface of the pipes. This coating acts as a barrier, preventing direct contact between the pipe and the surrounding soil or water. Additionally, cathodic protection systems, such as impressed current or sacrificial anode systems, can be employed to further protect the pipes. These systems help to control and redirect stray currents, minimizing their impact on the ductile iron pipes and preventing corrosion.

Send your message to us

DUCTILE IRON PIPEs K8 CLASS DN1000

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 32 pc

- Supply Capability:

- 3000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords