Duct Iron Pipe DI Pipe Flange Pipe with Cast ISO 2531 EN545

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ductile iron pipe fittings:

Dimensions standard:

ISO2531: 50-1000mm, PN10/16

BS4772: 50-1000mm, PN10/16

EN545: 50-1000mm, PN10/16

Connecting mode:

Flanged

Socketed

Mechanical connection

Loose flanged

Coatings:

Inner lined with cement and outside coated with zinc plus bitumen

Inner and outside coated with epoxy resin

Inner and outside coated with fusion bonded epoxy resin

Quality:

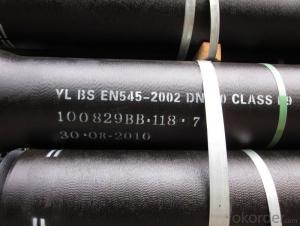

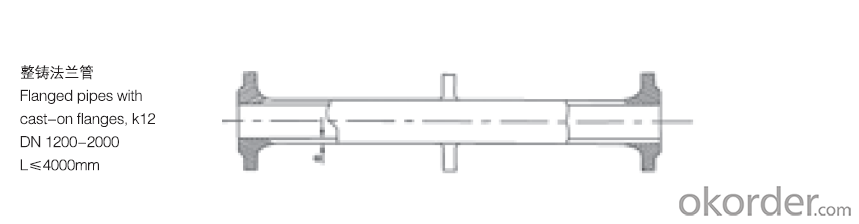

ISO 2531 or EN 545 Standard K9 Class, K12 Class

1. ISO 9001 Certificate

2. ISO 2531 & EN 545 Certificate

3. WRAS Potable Water Certificate for FBE Internal Lining

4. WRAS EPDM Rubber Gasket or NBR Rubber Gasket

5. DN80mm - DN2000mm

6. Black Bitumen or Blue FBE / Epoxy Coating

7. Lengh = 6m or cut into 5.6m, 5.7m, 5.8m

8. Client's Brand Customization Allowable

9. Container or Bulk Loading / Shipping

10.Delivery within one Month or According to Client's Order Quantity

11. Support Client or The Third Party Inspection before Shipment

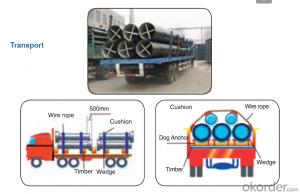

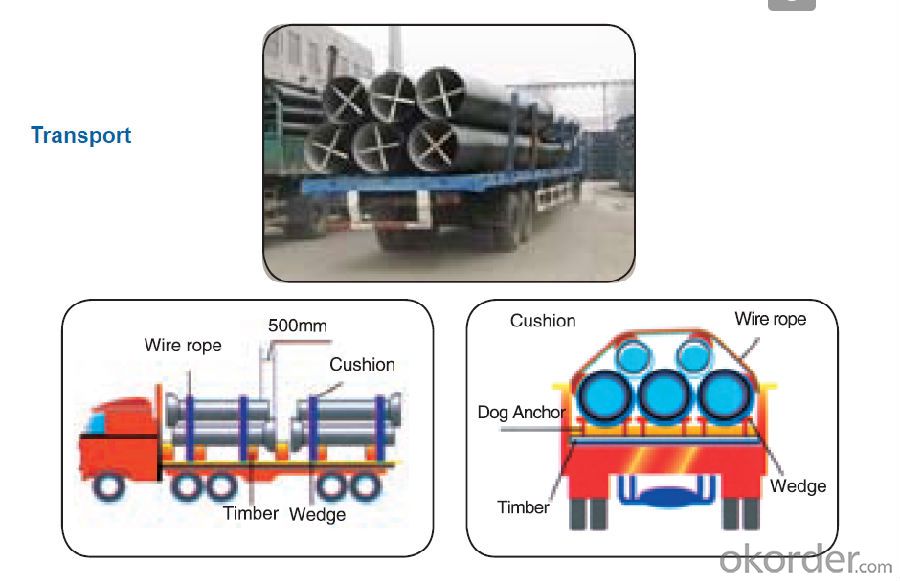

Transport:

- Q: How do ductile iron pipes handle traffic vibrations?

- Ductile iron pipes are highly resistant to traffic vibrations due to their inherent strength and flexibility. These pipes have the ability to absorb and dissipate the energy generated by traffic vibrations, minimizing any potential damage or stress on the pipes. Additionally, their sturdy construction and high tensile strength make them less susceptible to cracking or breaking under the impact of traffic-induced vibrations. Overall, ductile iron pipes provide excellent performance and durability in handling traffic vibrations.

- Q: Can ductile iron pipe be repaired if it gets damaged?

- Yes, ductile iron pipe can be repaired if it gets damaged. Various repair methods such as welding, clamping, and epoxy lining can be used to fix cracks, leaks, or other types of damage in ductile iron pipes. However, the repair method depends on the nature and extent of the damage, and it is recommended to consult with experts or professionals for proper repair procedures.

- Q: What is the expected fire resistance of ductile iron pipes?

- The expected fire resistance of ductile iron pipes can vary depending on several factors such as the thickness of the pipe walls, the quality of the installation, and the surrounding conditions. However, generally speaking, ductile iron pipes have a high fire resistance due to their durable and heat-resistant material composition. Ductile iron is made by adding a small amount of magnesium to cast iron, which enhances its strength and flexibility. This makes ductile iron pipes less susceptible to cracking or breaking under high temperatures compared to other materials like PVC or HDPE pipes. In terms of fire resistance, ductile iron pipes can withstand high temperatures for an extended period of time without significant structural damage. They have been tested and proven to maintain their integrity in fire conditions for up to 2-4 hours, depending on the specific pipe design and installation. It is important to note that while ductile iron pipes have a high fire resistance, they are not fireproof. In case of a fire, it is crucial to follow proper fire safety protocols and consult with professionals to ensure the safety of the system and surrounding infrastructure.

- Q: How does ductile iron pipe perform in areas with high soil erosion?

- Ductile iron pipe is known for its exceptional strength and durability, making it a reliable choice for areas with high soil erosion. Its unique composition, which includes graphite nodules, allows it to be both flexible and resistant to fractures or cracks, even in challenging environments. This makes ductile iron pipe highly capable of withstanding the impact of soil erosion. In areas with high soil erosion, the soil particles can scrape against the surface of the pipe, potentially causing abrasions or damage. However, ductile iron pipe's thick wall thickness and corrosion-resistant coating provide an effective barrier against these abrasive forces. This means that even in areas with significant soil erosion, ductile iron pipe can maintain its structural integrity and functionality. Moreover, ductile iron pipe's ability to resist corrosion further enhances its performance in areas with high soil erosion. Soil erosion often leads to an increased presence of moisture, which can accelerate the corrosion process of certain materials. However, ductile iron pipe's protective coating, typically made from zinc or epoxy, acts as a shield against corrosion, ensuring its long-term performance and reliability. In summary, ductile iron pipe demonstrates excellent performance in areas with high soil erosion due to its strength, flexibility, and resistance to fractures or cracks. Its thick wall thickness and corrosion-resistant coating make it highly durable against abrasive forces and corrosion, allowing it to withstand the challenges posed by soil erosion. As a result, ductile iron pipe is a dependable choice for infrastructure projects in such areas, providing long-lasting and efficient water and wastewater transportation systems.

- Q: Can ductile iron pipe be used for industrial process piping?

- Yes, ductile iron pipe can be used for industrial process piping. Ductile iron pipe is known for its strength, durability, and resistance to corrosion, making it a suitable choice for various industrial applications. It can handle high-pressure systems and is often used in industries such as water and wastewater treatment, oil and gas, chemical processing, and power generation. Additionally, ductile iron pipe is easy to install and has a long lifespan, making it a cost-effective option for industrial process piping.

- Q: How much is the installation of cast iron pipe drainage 1 meters?

- Ductile iron pipes mainly called centrifugal ductile iron pipe, it has the properties of nature, iron and steel, excellent corrosion resistance, good ductility, good sealing effect, simple installation, mainly for municipal, industrial and mining enterprises, water supply, gas, oil etc..

- Q: Are ductile iron pipes suitable for use in mining tailings pipelines?

- Yes, ductile iron pipes are suitable for use in mining tailings pipelines. Ductile iron has excellent strength and durability properties, making it capable of withstanding the high pressure and abrasive nature of tailings. Furthermore, its corrosion resistance and ability to withstand harsh environmental conditions make it a reliable choice for mining applications.

- Q: Why does the construction wastewater system use ductile iron pipes instead of galvanized steel tubes?

- The cost is low, the construction cost is low, and the schedule is fast. Such as PVC, PE double wall corrugated pipes, etc..

- Q: What's the difference between ductile iron pipe and cast iron pipe?

- Cast iron pipe and ductile iron pipe, cast iron pipe, also known as the cast iron pipe, ordinary gray iron. Often used in socket connection, the sealing material is usually cement rigid interface.

- Q: Ductile iron pipe joint leakage

- The main reason for the leakage is that the installation is not in place, resulting in the loss of the apron. Sealed with cement or pipe head Hough section. Recommend the use of Hough section fast and convenient, and there is no menace from the rear.

Send your message to us

Duct Iron Pipe DI Pipe Flange Pipe with Cast ISO 2531 EN545

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords