Dry Method Sand Making System for Concrete Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 60 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

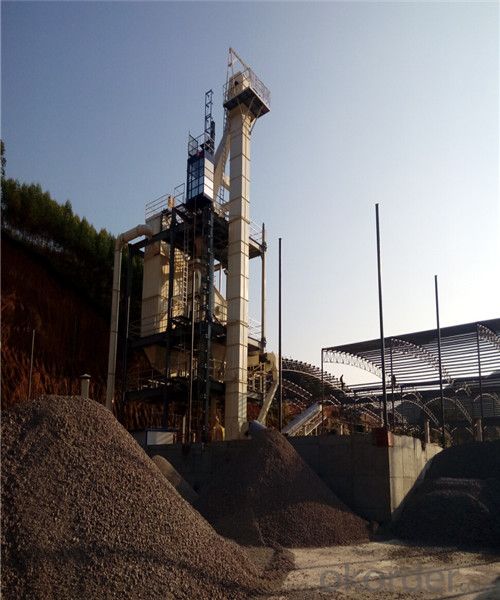

Dry Method Sand Making System introduction

Dry Method Sand Making System is researched and designed by the senior engineer of CNBM with 10 years experience , it combined all the machine into one equipment, including sand making , separating , dust separation and collection etc for crushing ,grinding ,stone-breaking-stone and reduce the motor power for the main machine .The final products is with stable gradation, cubic shape, adjustable fineness modulus . We control the stone powder content to meet National Standard effectively with Stone-Powder Separation Patent Technology . The final products from our Dry Method Sand Making System meet the requirement for high characteristic concrete and dry-mixed mortar . It saves much cost because the comprehensive performance of the final products is better than river sand and mountain sand . It leave out the heating procedure and save cost with the improved durability and strength and other performance for concrete . The final sand can be used directly without water washing . It is the first choice equipment for sand making in quarry , concrete industry, dry-mixed mortar industry without mixing river sand to adjust the ratio .

Dry Method Sand Making System Advantage :

1. The sand mould is premium.

During production process, “pounding, milling and rock hit rock” are all in one. Finished sands are gradating stability and in good shape (containing 10% or less micro-grading flour). All the sands are almost no flakiness. The finished sands are with more angular, nearly circular, fineness modulus (2.3 ~ 3.0). The percentage of powder content (below 10%) is adjustable. All the performance indicators are meets the national “Architecture Sand” standard GB14684-2011.(patented equipment).

2. Low energy consumption.

The energy consumption is 3kW/t which save 60% energy than the similar international or domestic products, greatly reducing the cost of production. Suit for the concrete sand cause its disposable sand ratio reach 0~4.75mm (>70%). And suit for dry-mixed mortar cause its disposable sand ratio reach 0 ~ 2mm(>40%).

3. Feed size range.

Feeding size from 0mm ~ 120mm.

4. Low noise.

Lower than traditional sand system 20db.

5. Wide range crushing.

In addition to variety of limestone, it can be used for crushing tailings, cobblestone, construction waste and other materials.

6. Environmental Friendly.

The system is equipped with advanced dust removal program, the working environment will be without any dust pollution.

7. Compact Structure.

100 ~ 200m2 (Transporting in parts available, finishing the installation and commissioning in a week normally), low height, the maximum height is 10 ~ 20 m.

8. High degree of automation.

Saving human resources greatly, because the control system is integrated in an operating room.

Dry Method Sand Making System parameter:

SJ-100 | Feed particle size | Feed quantity | Discharge quantity | Material particle size | Power |

The host system | 0~30~80mm | 120t | 0~4.75mm(>70%) | 150kW | |

Feeding system | 0~30~80mm | 120t | 20kW | ||

Discharge system | 0~3mm(product) | 80t | 0~2mm(>40%) | 15kW | |

De-dusting system | 15000m3/h(wind) | Powder quantity adjustable | Fine powder | 25kW | |

Sieving system | 0~30mm | 120t | 120t | 0~3mm;3~4.75mm;>4.75mm | 11kW |

Others | 15kW | ||||

Total power | 236kW | ||||

SJ-150 | Feed particle size | Feed quantity | Discharge quantity | Material particle size | Power |

The host system | 0~30~100mm | 160t | 0~4.75mm(>70%) | 220kW | |

Feeding system | 0~30~100mm | 160t | 45kW | ||

Discharge system | 0~3mm(product) | 110t | 0~2mm(>40%) | 30kW | |

De-dusting system | 20000m3/h(wind) | Powder quantity adjustable | Fine powder | 30kW | |

Sieving system | 0~30mm | 160t | 160t | 0~3mm;3~4.75mm;>4.75mm | 15kW |

Others | 20kW | ||||

Total power | 360kW | ||||

SJ-300 | Feed particle size | Feed quantity | Discharge quantity | Material particle size | Power |

The host system | 0~30~120mm | 320t | 0~4.75mm(>70%) | 400kW | |

Feeding system | 0~30~120mm | 320t | 60kW | ||

Discharge system | 0~3mm(product) | 220t | 0~2mm(>40%) | 45kW | |

De-dusting system | 40000m3/h(wind) | Powder quantity adjustable | Fine powder | 45kW | |

Sieving system | 0~30mm | 320t | 320t | 0~3mm;3~4.75mm;>4.75mm | 22kW |

Others | 20kW | ||||

Total power | 592kW |

Note:

1.These parameters of sand production make limestone as a reference base.

2.Feed requirements in accordance with international standards, stone moisture is less than 5%.

3.Sand production will change according to different stone and raw material.

4.Designed by site-specific, picture is only for reference.

FAQ

1. Our Advantage

We are one of the largest State-Owned Enterprises in China which established in 1984 , has 30 years experience in stone crushing and sand making industry , have rich experience , We have professional R&D design department and technical engineer , we can make the design and suggest the suitable machine as per customer’s special requirement and any products is customized .

2. Quality Guarantee

We have Strictly Quality-Inspection Department and we also can apply SGS and other Third-Party Agency to check the Products to make sure superior quality .

3. Payment Terms :

Generally we accept TT and LC , if project requirement , we can accept DP and LC After Sight .

4. After Sales Service

We can send our engineer and sales manager to your job site for work and installation direction and make training for your workers .

5. Time of Delivery

We can overdo work for the customer to make sure the fast shipment

- Q: A guy at the gym said that mma gloves cant be used for punching bags, is that true because i cant stand having though huge lightbulbs on the end of my hands.Does anyone train with mma gloves on punch bags?

- A windshield won't do much below 45 MPH. It will help block some wind at highway speed, but is not necessary. Personally, I prefer to not have a windshield or a fairing. I like the feel of the wind on my body. I always wear a full face helmet though. In the past, I wrecked enough times on the track to really appreciate their value.

- Q: I accidentally left the furnace on while I was at work, it wouldn't stop beeping when i got home! Ever since I moved in this new place about a week ago It has been hard for the kids I to get up in the morning???!!!

- Bad Rear Shocks and/or Broken Springs. Broken Sway Bar could also do it.

- Q: pleez tell me? lol

- Muncie M-22 4-speed

- Q: I work at a restaurant where the chefs remove the cooked meat from the skewer with the same cloth again and again, as it seems very unhigyienic I suggested they use other method but the head chefs is adamant that's the only way to do it and it's not a problem. Would that be right? If not how shoud it be done?

- the speed bumps did not do anything to the water pump ! it just happened the water pump went out the same time you went over the bump !

- Q: Why does the hammer crusher work with strong vibration?

- This situation occurs mainly in the following aspects: 1. bearing clearance exceeds the limit or has been damaged. Generally, new bearings are used to solve such problems; 2., the hammer pieces are installed incorrectly when repairing and assembling the crusher.

- Q: What is the hammer piece of the crusher?

- Our factory specializes in the production of nickel based tungsten carbide hammer chip, hammer piece is the hammer hammer pieces of metal parts vulnerable parts

- Q: I am on a Macbook pro, and the program Skype on my computer has access over many system preferences, including volume control. Skype will change the input volume of my microphone in a seemingly unorthodox way, and I don't want it do to this any longer. I can't seem to find any options in Skype or System Preferences that will restrict Skype's access to my computer's options Are there any terminal commands I can use instead?Thanks in advance for your help. Much appreciated!

- i recommend to format everything that's on on your computer. except OS

- Q: My headphones broke but, nothing of it has to do with it not workig anymore or with wires. Its simple because, one headphone piece (the right) broke off the main headset. So now I pretty much have one headphone attached to the main headset and the other one which isnt attached and to the side.

- Before you try to fix anything, check with Skull Candy since they generally have some kind of lifetime warranty, where they say they will at least give you a 50% discount on the next product you buy from them, even if they broke like yours did. If you want to try to patch it back together yourself, then from what I can see, I might try roughing the surfaces a little and using a good strong epoxy to hold it all together. Be patient and let it dry/cure sufficiently before stressing it much. Sorry I can't think of any particular brand or type of glue or epoxy to suggest at the moment. Research the adhesive first (some dry more firm/brittle, others might dry softer, or may stick to certain surfaces more securely). Drawbacks to fixing might include the earpiece not pivoting quite the same as before, depending on how it all fits together (which is harder to see in this picture), and possibly the epoxy being visible (depending on how cleanly the gluing job goes).

- Q: who invented the can crusher?

- You mean the little one used on aluminum cans? Probably about 20 guys following on -- A drunk after WWII when beer cans were made of steel and crushing a can was an indication of strength, crushing it against your forehead being good proof you were a strong moron.

- Q: Star Trek Enterprise takes place at an earlier date than The Next Generation.

- Not more advanced (obviously) but Phlox's methods are vastly different. Phlox used what we would call 'natural' medicine, employing a great deal of cross-species work, such as using the enzymes of alien creatures to treat human diseases. His methods were most akin to the 'witch doctors' or 'native healers' who used plants and animals to effect cures. Like the Medicine Men, the methods worked because he studied the inter-relationships between species. McCoy and Crusher and Bashier and 'Zimmerman' used technological methods of cures.

Send your message to us

Dry Method Sand Making System for Concrete Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 60 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords