OPP Packaging Tape with Double Sided PE Foam EVA Foam Yellow Glassin Paper Hot Melt/Solvent Adhesive

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m

- Supply Capability:

- 2000000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

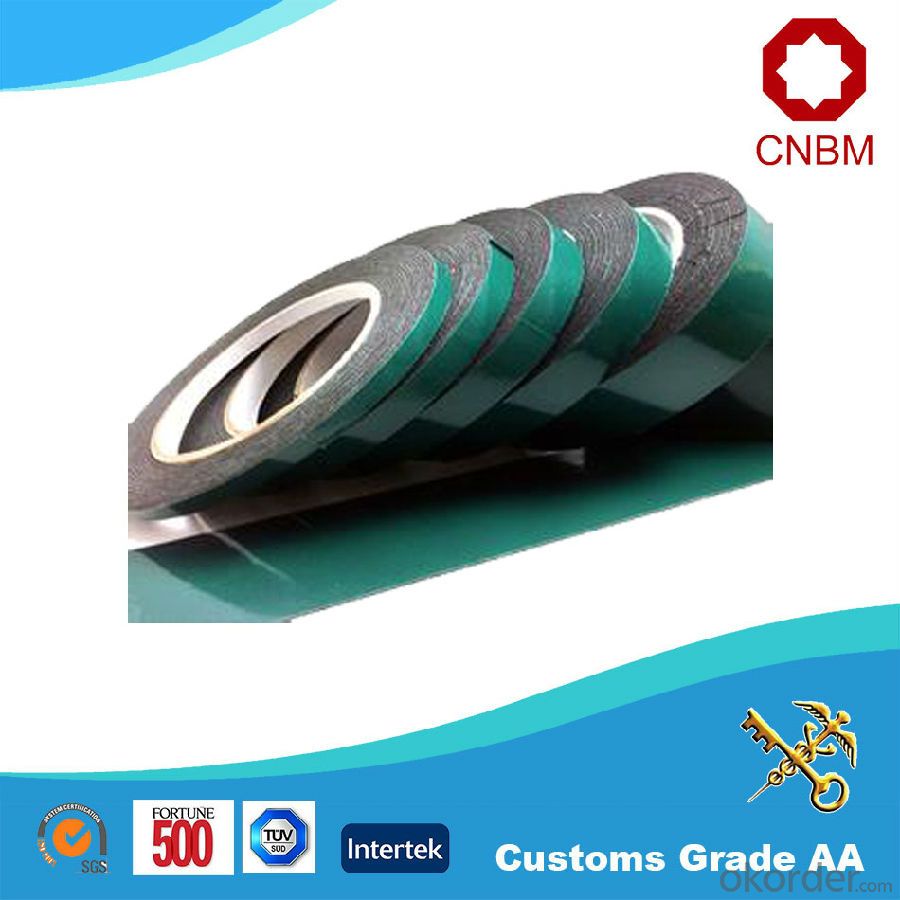

Double Sided Tape with PE Foam EVA Foam Yellow Glassin Paper Hot Melt/Solvent Adhesive

Product Description

Double Sided Foam Tape is of PE foam or EVA foam as the carrier, coating with hot melt adhesive, solvent based acrylic. Double Sided Foam Tape is widely used in the auto, electronic and construction industries.

FEATURES:

l Excellent in adhesion and flame retardant

l Resistance to cold, heat and aging.

l High Temperature stability

l High mechanical strength and good impact resistance

l Ideal for use in dispensers

l Printable

Data Sheet

| Item NO. | DSP08YM |

| Carrier | PE Foam |

| Adhesive | Hot melt/Solvent |

| Thickness (mm) | 0.8 |

| Density (kg/m3) | 120 |

| Peel Adhesion (N/25mm) | 12 |

| Holding Power (H) | 100 |

| Packing | Carton |

| Delivery | With 10-20 days after deposit |

| Payment | TT & LC |

Authorized Certificate

Production Line

Exhibition Domestic and Oversea

Company

China National Building Materials Group is a state-owned company. As World Top 500 companies, we have clients from over 160 countries and wholly-owned overseas subsidiaries and branches in 10 countries. We supply adhesive tape for over twenty years.

We supply various adhesive tapes: cloth tape, double sided tape, PVC tape, aluminum foil tape, Opp tape, masking tape and so on. All our products have been SGS and ISO9001 certified and exported with Grade AA approval. The quality and performance all meet the advanced international levels.

We not only own professional manufacturers in China, but also work with many famous brands as agents. We can provide OEM Design & Brand as you required.

FAQ

1. Why choose us?

20 Years Experience USD1.6 billion yearly sales

World Top 500 Enterprise

OEM service, supported by strong R&D team

A short lead time

Quality guarantee with third party certification

One-step service: transportation, capital etc.

2. What can we do for you?

Professional consultation on your local market

Custom-made advices for your need

Free samples

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Satisfactory sales service

3. Delivery time

7-25 days after receiving the deposit

4. Packing and Shipping

36 Rolls per Caron.

5. What is other specifications of double sided tape?

Double Sided Tissue Tape: widely used for bonding, fixing for leather, foam, sponge, garment, shoe, luggage, plastic, paper splicing and stationery.

Double Sided PET Tape is wildly used for carpet fixing, flying splice operations on film, bag cover sealing, bounding, foam lamination and others.

Double Sided Cloth Tape is ideal for carpet fixing, bag cover sealing, bundling, flying spice operations and other industrial.

- Q: How does packaging tape perform in high-temperature conditions?

- Packaging tape generally performs well in high-temperature conditions, but its effectiveness may vary depending on the specific type and quality of the tape. Most packaging tapes are designed to withstand a range of temperatures and are typically heat-resistant up to a certain degree. However, it is important to note that extreme temperatures, particularly those exceeding the tape's specified heat resistance limit, can affect its adhesive properties and overall performance. In high-temperature conditions, the adhesive on packaging tape may soften or weaken, leading to reduced bonding strength and potential tape failure. This can result in packages opening or becoming less secure during transit or storage. Furthermore, heat can cause the tape to become less flexible, making it more prone to cracking or breaking. Hence, it is crucial to select packaging tape that is specifically designed for high-temperature environments if you anticipate exposure to extreme heat. Certain types of packaging tape, such as fiberglass-reinforced or high-temperature resistant tapes, are better suited for withstanding high temperatures. These tapes are often made with special adhesives and materials that offer enhanced heat resistance and improved performance in extreme conditions. They are designed to maintain their adhesive strength, bonding capability, and structural integrity even when exposed to elevated temperatures. In summary, while packaging tape can generally withstand high-temperature conditions, its performance may be compromised if subjected to extreme heat. Using tapes specifically designed for high-temperature environments can help ensure optimal performance and securely seal packages even in challenging conditions.

- Q: Can packaging tape be used for sealing pet food or treats?

- Indeed, pet food or treats can be effectively sealed using packaging tape. This tape guarantees a sturdy and reliable seal, ensuring the preservation and protection of the contents. However, it is crucial to verify the safety of the tape employed, ensuring its non-toxicity and absence of any harmful substances that could potentially be consumed by the animals. It is highly recommended to opt for pet-safe packaging tape specifically crafted for the purpose of sealing pet food or treats, as it adheres to all necessary safety standards and regulations.

- Q: Can packaging tape be used for sealing packages with fragile artwork or sculptures?

- Yes, packaging tape can be used for sealing packages with fragile artwork or sculptures. However, it is important to choose the right type of packaging tape to ensure the protection of the artwork. Generally, it is recommended to use a high-quality, heavy-duty packaging tape that is specifically designed for shipping and handling delicate or fragile items. These tapes are often reinforced with fibers or have extra adhesive strength to provide a secure seal and prevent damage during transportation. Additionally, it is advisable to use proper cushioning materials such as bubble wrap or foam padding to protect the artwork inside the package.

- Q: Can packaging tape be used for sealing medical supplies or equipment?

- No, packaging tape should not be used for sealing medical supplies or equipment. Medical supplies and equipment require proper and sterile sealing to ensure the safety and integrity of the contents. Packaging tape is not designed for medical purposes and may not provide an adequate seal. It is important to use medical-grade sealing materials that meet the required standards and regulations to prevent contamination and ensure the effectiveness of the medical supplies or equipment.

- Q: Can packaging tape be used for securing pallet loads?

- Yes, packaging tape can be used for securing pallet loads. It is commonly used to reinforce and stabilize palletized goods by securing them together, preventing shifting or toppling during transportation or storage.

- Q: Can packaging tape be used for sealing packages with heavy-duty construction materials?

- Yes, packaging tape can be used for sealing packages with heavy-duty construction materials. However, it is recommended to use a high-quality, heavy-duty packaging tape specifically designed for securing heavy items.

- Q: What's the tape for sealing tape?

- BOPP film can be produced by tube or flat film method. The BOPP films obtained by different processing methods have different properties. The BOPP film produced by the flat film method has a higher strength ratio (up to 8-10), so the strength is higher than that of the tube film, and the uniformity of the film thickness is better.

- Q: Does packaging tape have any specific certifications or standards?

- Yes, packaging tape can have specific certifications or standards. Some common certifications or standards for packaging tape include ISO 9001 (quality management), ISO 14001 (environmental management), and ASTM D1974 (standard specification for sealing and securing pressure-sensitive tape for packaging). Additionally, certain industries may have their own specific certifications or standards for packaging tape, such as food-safe certifications for packaging tape used in the food industry.

- Q: Can packaging tape be used for sealing foam?

- Sealing foam can be achieved by using packaging tape. While packaging tape is commonly used for sealing boxes and packages, it can also be effectively used to seal foam. To create a tight seal, it is important to make sure that the tape is securely adhered to the foam surface by applying pressure after it has been applied. It is advisable to use a tape specifically designed for sealing foam, as these tapes usually have stronger adhesive properties and are more resistant to temperature changes and moisture. In conclusion, packaging tape can be a convenient and effective choice for sealing foam.

- Q: How does packaging tape perform on low-friction surfaces?

- Packaging tape generally does not perform well on low-friction surfaces. Low-friction surfaces, like smooth plastics or certain types of laminates, lack texture and adhesion, making it challenging for packaging tape to effectively stick and hold. The lack of friction allows the tape to easily slide or peel off the surface, compromising the integrity of the package. In such cases, it is advisable to use alternative methods like shrink wrapping, heat sealing, or adhesive sprays specifically designed for low-friction surfaces. These alternatives provide better adhesion and ensure the package remains securely sealed during handling and transportation.

Send your message to us

OPP Packaging Tape with Double Sided PE Foam EVA Foam Yellow Glassin Paper Hot Melt/Solvent Adhesive

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m

- Supply Capability:

- 2000000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords