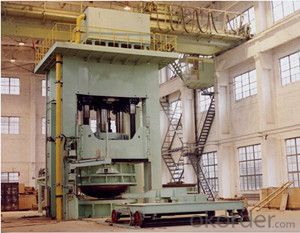

die forging hydraulic presses and isothermal die forging hydraulic presses

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TYHI designs and manufactures common die forging hydraulic presses with various specifications, such as multidirectional die forging hydraulic presses and isothermal die forging hydraulic presses and others per customers’ requirements.

Our main products include lifting equipment, forging equipment, rolling equipment, excavation equipment, coke oven equipment, coal chemical equipment, wind power generating equipment, oil film bearings for rolling mills, gear drive equipment, train wheels and axles, forgings and castings and project contracting.

Our key products include our 1200t EOT crane, our 500t ladle crane, our 75m³ shovel for mining, our Φ180mm continuous rolling production line, our 110 MN aluminum alloy extrusion press and our 7m top charging coke oven equipment.

TYHI’s products are widely used in the metallurgical, mining, energy, transportation, aerospace, chemical, rail, ship building, environmental protection and various other industries. Many products designed and manufactured by TYHI have filled gaps in the domestic market. Furthermore, we have created 360 nationally and internationally recognized products which have been exported to approximately forty countries and regions.

TYHI is now delving further into the development of the rail, engineering machinery, new energy, and maritime equipment fields. We have established a new production base in the Binhai New Area of Tianjin to facilitate the transportation and export of large-sized equipment. Our second wheel production line is currently under construction. We have also established production lines for wheels, axles and wheel sets for use at speeds above 200 km/h.

We are now turning our focus to international markets which we are certain can benefit from our high quality products and service. As we are constantly innovating and improving, we have no doubt that we will meet and even exceed our customers’ expectations.

- Q: How is this pneumatic binder? What's wrong with it? Stamping machine above.

- This can be said that the tooling equipment to do the tooling equipment, what specific to see what products to determine

- Q: Good hydraulic press or punching machine

- If there is a need to enter my Baidu space home page to see my contact information.

- Q: Fenghua robot production of stamping robot, is fully automatic?

- Stamping robots are generally automated, fully automated need to contain automatic feeding of the silo (sheet, roll, bar material has a corresponding automation equipment), loading and unloading of the manipulator, and the storage of the conveyor (conveyor.

- Q: How to distinguish between stamping machine installed mold to pad pad it?

- in order to take the red down the parts, but also need to add a hammer under the mold, the mold pad up overhead

- Q: How to improve the capacity of a single punching machine

- If you want to quickly improve the productivity of a workshop is not anxious to invest in new equipment and automation, capacity is not the higher the better the blind, the better, but with the quality of products produced together.

- Q: What are the structure of the press?

- Between the connecting rod and the slider between the need for circular motion and linear motion of the transfer point, the design of roughly two kinds of institutions, one for the ball, one for the pin (cylindrical), through this body will be circular motion

- Q: How do the hooks press a one-time press?

- Open the cost of the mold need to go up, this number is not the case, or with artificial plus molded into a good

- Q: Can MnZn ferrite powder be molded with a press?

- Of course you can, but need to choose the right tonnage based on your actual product size, you can consider 1.5 tons per square centimeter.

- Q: My home next to the punch factory vibration on my house caused a relatively large impact on the success rate?

- The photo did not ah, the vibration to measure really have a shock, the actual distance, 3 meters away from my home

- Q: The hands were stamping machine Qi rush, how much money to pay

- I encountered a case last time, a year before a worker left hand thumb did not, the company probably compensated 80,000.

Send your message to us

die forging hydraulic presses and isothermal die forging hydraulic presses

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords