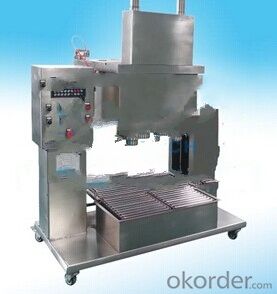

DCS30G Gravity Type Automatic Filling Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Applications:

Applicable to various coatings, inks, automotive paint, furniture paint, adhensives (glue), resin, chemical solvents, curing agents, lubricants, shoes glue, spray glue, and all kinds of liquids which can flow.

Function:

·Digital input to set weight and 10 recipes can be saved;

·With working status indicator and clock display;

·Tare inspection triggers all-position barrel putting and filling operation;

·GW/NW (barrel tared automatically) two filling modes;

·Automatic zero position tracking, barrel quantity accumulation and weight accumulation;

·Automatic weight error correcting;

·Automatic clear to zero after start-up and there is power-off protection device;

·Protection device against emergency stop;

·Factory default setting can be restored in case of misoperation;

·Fault detecting function makes maintenance easier;

·Easy moving, explosion-proof configuration and simple operation.

Feature:

DCS30G-FB-II explosion-proof filling machine is designed according to customer’s requirement and has such features as two filling outlets to be operated by one worker. The barrel position can be adjusted according to worker’s habbit. The filling outlet height is adjustable and fit for round, square, and oblate barrels with various mouth diameters. With roller conveyance, it is easy to move around and the temporary stock tank is easy to clean. Alternative outlets in big and small sizes can be used for filling different materials. two-speed filling is “fast and accurate” and filling stability is good. It can effectively improve filling speed, reduce wastage, save cost and alleviate worker’s work load.

Weighing range | ≤40 kg | Barrel specification | ≤diameter350×height400(mm) |

Graduation value | 1g、2g、5g、10g | Power supply | Ac220∨±10% 50HZ |

Accuracy level | X (0.5) 级 | Air source | 0.5Mpa |

Filling speed | 12-20barrels/min | Dimension | 1500×580×1300(mm) |

2.

Weighing range | ≤40 kg | Barrel specification | ≤diameter350×height400(mm) |

Graduation value | 1g、2g、5g、10g | Power supply | Ac220∨±10% 50HZ |

Accuracy level | X (0.5) 级 | Air source | 0.5Mpa |

Filling speed | 12-20barrels/min | Dimension | 1500×580×1300(mm) |

3.

Weighing range | ≤40 kg | Barrel specification | ≤diameter350×height400(mm) |

Graduation value | 1g、2g、5g、10g | Power supply | Ac220∨±10% 50HZ |

Accuracy level | X (0.5) | Air source | 0.5Mpa |

Filling speed | 8-12barrels/min | Dimension | 1500x600x1300(mm) |

- Q: The role of food packaging machinery

- Packaging is the necessary condition for products to enter the circulation field, and the main means of packaging is the use of packaging machinery. With the development of the times and the progress of technology, packaging machinery is playing a more and more important role in the field of packaging. The main functions of packaging machinery are as follows:

- Q: What are the main functions of packaging machinery?

- In order to meet the requirements of many customers, our company has learned from all aspects of the role of packaging machinery and equipment, so that we need customers for reference

- Q: What are the main plastic forming processes?

- 3. cold pressing molding. Cold pressing molding is also called cold pressing sintering molding. The difference between the cold press molding and the ordinary compression molding is that the material is pressurized and molded at room temperature. The mold after release can be heated or cured by chemical action. This method is used in the forming of polytetrafluoroethylene and some high temperature resistant plastics (such as polyimide, etc.). The general process is three steps of billet sintering cooling.4. transfer molding. Transfer molding is a molding process for thermosetting plastics. When molding, the mold is heated and softened in the heating chamber and then pressed into the mold cavity where it has been heated. According to the different types of transfer molding equipment form: trap type; the tank; the piston.The requirement of plastic molding for transfer molding is that the plastic should have a greater fluidity before reaching the curing temperature, and the curing rate must be faster at the curing temperature. Phenol, melamine, formaldehyde and epoxy resins can meet this requirement.Transfer molding has the following advantages: less waste edge products, can reduce the processing quantity; second molding with fine or brittle insert and perforation of the products, and can keep the insert and the hole position is correct; the product performance is uniform, accurate size, high quality; the mould wear small. The disadvantage is that the manufacturing cost is high compression mold die; the plastic loss; the fiber reinforced plastics for fiber orientation and anisotropy; and around the insert around the plastic, sometimes due to melting is not strong and make the products according to the strength reduction.

- Q: What is the price of a small jujube packing machine?

- Mainly see what some requirements, automatic metering packaging or vacuum packaging machine, after understanding can determine the price.

- Q: What machine does the packing carton machine have?

- Since its establishment, the company has continued to provide specialized packaging equipment and transportation equipment for domestic first-class enterprises, as well as perfect solutions for automated transportation systems.

- Q: The role of packaging equipment in packaging equipment

- Some products, such as food and drug packaging, according to the health law is not allowed to use manual packaging, because it will pollute the products and packaging machinery to avoid direct contact with the staff of food and medicine, to ensure the quality of health.(8) it can promote the development of related industriesPackaging machinery is a comprehensive science which is related to many subjects, materials, process and equipment, electronics, electrical appliances, automatic control and other related disciplines, requires the simultaneous and coordinated development, any discipline problems will affect the overall performance of packaging machinery. Therefore, the development of packaging machinery will effectively promote the progress of related disciplines. In addition, in order to meet the needs of high-speed packaging machinery packaging, the relevant front and rear processes are bound to adapt, and also promote the simultaneous development of related processes.

- Q: What is the name of the paper used in packing machine parts and yellow?

- Vapor phase rust proof paper is coated with vapor phase corrosion inhibitor on the base of antirust base paper (surface like kraft paper, but with chloride ion and sulfate ion limit requirement)

- Q: What are the structures of the packaging machinery?

- Is far from a professional engaged in "packaging machinery" research and development, production, sales as one of the multinational enterprise groups. It is the largest manufacturer of packaging machinery in china. Located in the Chinese science and Education City - Hefei, the geographical position is superior, the traffic condition is convenient, and the sale network extends the whole country. Is far from, with a group of the world's top machinery manufacturing R & D team, specializing in all walks of life packaging enterprises, for the efficient production of enterprises to provide power. It is a large enterprise that put forward the concept of packaging automation earlier in china. Brand with strong economic strength, first-class R & D level, advanced business philosophy and good brand service, more and more people all over the world are respected and trusted. The entire manufacturing process in full accordance with the highest standards of global manufacturing; at the same time according to the quality standard of global market development process, operating procedures and quality control system of production, all is "far Machinery" have reached world-class standards. "Far distance machinery" combines the characteristics of all kinds of products in China, such as packaging machinery, food packaging machines, two times packaging machines, powder packaging machines, particle packaging machines, liquid packaging machines, weighing machines, and so on. It is well received by Chinese enterprises!

- Q: What does the mechanical equipment include?

- Track roller type rail flat car track car battery car nailThese are, want to know more, you can go to the network building equipment to see there

- Q: Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- 5009.101 determination of antimony in polyester resins and their moulding products for food containers and packaging materialsGB 13113 hygienic standard for polyethylene terephthalate moulding articles for food containers and packaging materials

Send your message to us

DCS30G Gravity Type Automatic Filling Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords