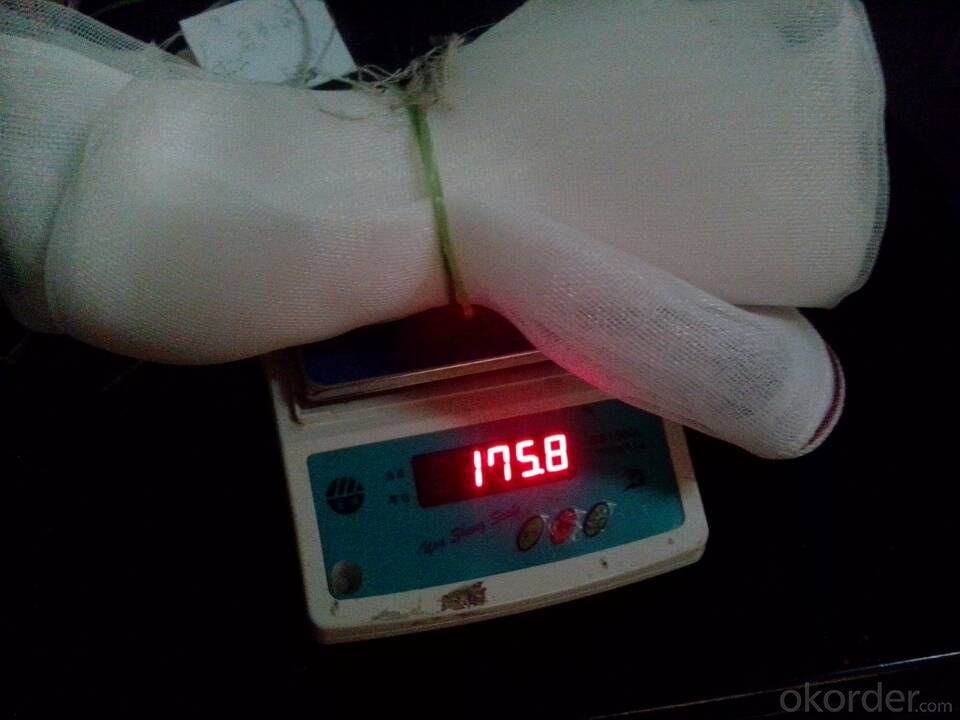

Date Bag Monofilament170g 100cmx120cm PE Material UV treatment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 950000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

About the enterprise group - CNBM Group

China National Building Material Group Corporation (CNBM),is the largest building materials and equipment group in China.

• Established in 1984 with approval from the State Council

• A Central Enterprise under direct supervision of SASAC in 2003

• Over 100,000 employees

• 20 companies under direct management

• Among which 6 were listed companies, including 2 overseas listed.

Material: polyethyelene(HDPE)

Product Name: Date plam bag

1.widely used packing dates

2.durable,fashionable,

3.recyclable

4.environment-friendly products.

Material: polyethyelene(HDPE)

Specifications:

PE date bags

Made by Virgin HDPE

Weight:170g,175g 180g 220g 225g 280g 470g

Size: 120x100cm,100x400cm,90x140cm,90x120cm,105x135cm

Color: Green,Black, White

Packing:500pcs/bale

16tons/40'HQ

Production capacity:2x40'HQ/month

Delivery time: About 15 days/40'HQ

Payment Terms: 30% prepayment before production, 70% against B/L copy.

We would like to provide you PE date bags with good quality ,large quantity and lowest price.

Expect to cooperate with you. If you are interested in our products, please feel free to contact us for more information.

- Q: What are the requirements of the mark on the cement packing bag?

- Label on cement packing bagCommon C25, C30, C35, C40 label is the cement packaging machine packaging cement mark, specific what label, drawings will generally indicate, general use C25 on the line, the greater the strength higher.

- Q: How are food bags made out?

- Packaging design: This is based on the requirements of the food company to design the layout of the food packaging bag, that is, the pattern of food packaging bags. A good design layout of food packaging bags can improve the sales of products. After all, the first eye is still very important. This pattern is generally designed by the food company and then given to the manufacturer of the bags.

- Q: What are the bags and bags?

- According to functional categories: high Yin diaphragm bag, cooking film bag, anti-static film bag, antibacterial film bag, anti fog film bag, vacuum bag, anti chemical film bag, oxygen packing film bag, air conditioning packaging film bag, etc.

- Q: What about the use of plastic bags?

- Now all walks of life have the use of plastic packaging bags, only grades, such as the food market is the worst, supermarkets in general, and then to food packaging non-toxic environmentally friendly plastic bags.

- Q: Three layer coextrusion material for packaging bags

- Five layer co extruded films composed of outer layer of multi ester copolymer, high mechanical strength, the second layer is ethylene methacrylate polymer, the third layer is the fourth layer of polyethylene, polyethylene, the inner layer is modified with ethylene propylene polymer. Five layer co extruded films performance of each layer as outer layer: providing excellent heat sealing and protection, good printing performance; the second layer is connected with the outer layer and third layer; third layer: providing vapor barrier and softness; fourth layer: connection layer and the third layer; inner layer: non-toxic, with compatibility infusion product good, excellent heat sealing and buffering external impact.

- Q: What kind of material is the food packing bag in general?

- Now the standard of living has improved, basically the food vacuum packed bag. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

- Q: What material is the packing bag for pure milk, please?

- W1l203 (station contact TA) should be food grade polyethylene, safe, easy to tear learn1986 (station contact TA), aluminum foil and polyethylene plastic film and paper interaction combined into polyethylene aluminum plastic composite packaging materials.

- Q: What does "13 silk" in vacuum packing bag mean?

- Silk is a mechanical worker, commonly known as "0.01 millimeters", the workers who have inherited the technology of Shanghai say "silk", and in the north they say "0.01 millimeters" as "Dao".

- Q: Printing solvent for food packing bag

- Look at the appearance of the solvent. Should be clear and transparent, if there are cloudy and floating objects, the batch of solvents should be used with caution.

- Q: How many kinds of packing bags are there in the packaged foods?

- You ask about food plastic packaging, it is generally packaged with composite bags, composite materials, polyethylene (PE), polypropylene, nylon, polyester. These are the main membranes. The film is made of stretch film and blow film. Dry frozen goods, generally cooked with PET/PE., such as high temperature, it is generally nylon, composite CPP, or other composite, many kinds. I am in Dongguan, Humen, food packaging, such as alcoholic peanuts, bags, red dates bags, mask packaging bags, washing powder bags, areca bags, milk powder bags, small fish bags.

Send your message to us

Date Bag Monofilament170g 100cmx120cm PE Material UV treatment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 950000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches