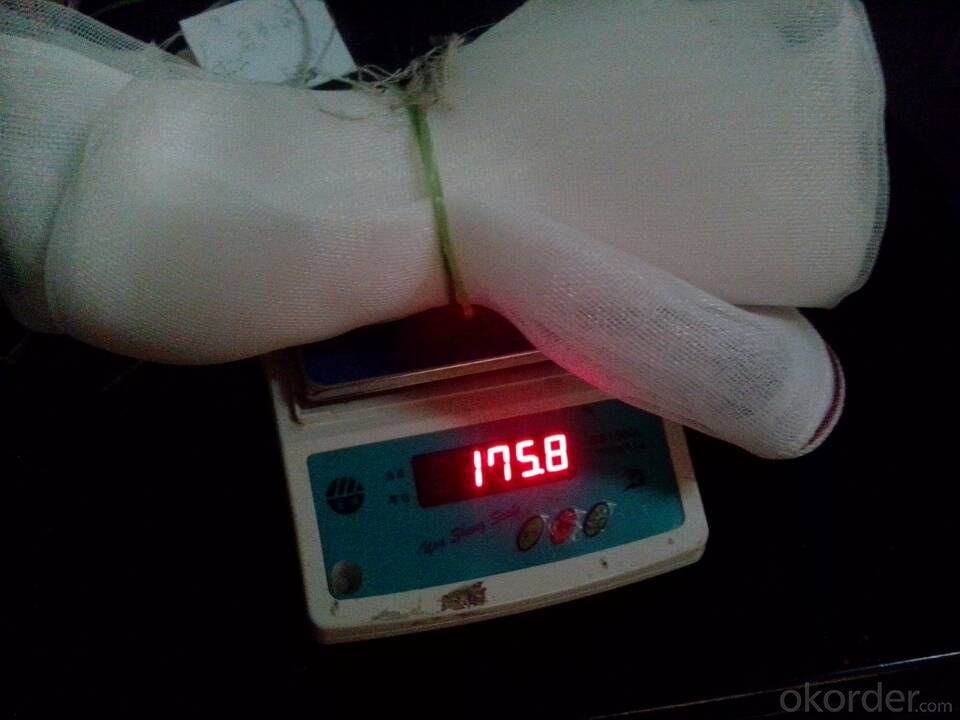

Date Bag 170g 90cmx120cm PE Material UV treatment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 950000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

About the enterprise group - CNBM Group

China National Building Material Group Corporation (CNBM),is the largest building materials and equipment group in China.

• Established in 1984 with approval from the State Council

• A Central Enterprise under direct supervision of SASAC in 2003

• Over 100,000 employees

• 20 companies under direct management

• Among which 6 were listed companies, including 2 overseas listed.

Material: polyethyelene(HDPE)

Product Name: Date plam bag

1.widely used packing dates

2.durable,fashionable,

3.recyclable

4.environment-friendly products.

Material: polyethyelene(HDPE)

Specifications:

PE date bags

Made by Virgin HDPE

Weight:170g,175g 180g 220g 225g 280g 470g

Size: 120x100cm,100x400cm,90x140cm,90x120cm,105x135cm

Color: Green,Black, White

Packing:500pcs/bale

16tons/40'HQ

Production capacity:2x40'HQ/month

Delivery time: About 15 days/40'HQ

Payment Terms: 30% prepayment before production, 70% against B/L copy.

We would like to provide you PE date bags with good quality ,large quantity and lowest price.

Expect to cooperate with you. If you are interested in our products, please feel free to contact us for more information.

- Q: What about the use of plastic bags?

- Now all walks of life have the use of plastic packaging bags, only grades, such as the food market is the worst, supermarkets in general, and then to food packaging non-toxic environmentally friendly plastic bags. There are advantages and disadvantages. If it is a new material, the printing ink is also non-toxic. You can use it safely. If you use recycled materials, there is a foul smell. That's bad. What's more, we will bring plastic bags to the cooked food, it is best to buy from the supermarket, come back after the food will be taken out, to avoid food and plastic bags long-term exposure, chemical reaction products. That's bad for your health.

- Q: Can food wrap be heated in a microwave oven?

- There are two sides to consider1. sealed pockets are heated in a microwave oven, and the pressure in the bag is too large to explode! There are all the instructions on the microwave (as well as the eggs, and a hole). The microwave food I eat is also packed in plastic bags, but there's always room for gas2. material of packing bagGeneral contact with food bags, requirements are made of polyethylene (non-toxic, burning candles oil smell), general temperature 130 degrees, this pocket no problem (including the regular supermarket to buy plastic wrap and plastic wrap)However, there are a lot of cheap pocket (for example in the market and vest bag, supermarket cashier for plastic bags) are made of PVC, and can not contact with recycled plastic food; do not to mention (characteristics: cheap, taste, burning acrid smell)And, if it's made of polyethylene, don't heat it up with high oil food

- Q: What material is the vacuum packing bag, please?

- And also consider the content and weight of the package to determine the reasonable use of the packaging materials. There is no static, and the right is the best.

- Q: Do vacuum packing bags have to be vacuum packed?

- Vacuum packaging bags and vacuum packaging machines are related. Vacuum packaging machine not only can complete vacuum extraction, but also can complete heat sealing packaging in vacuum, and ensure vacuum in vacuum bag can meet the requirement.

- Q: What's the raw material of the cement packing bag?

- The quality of cement packing bags directly affects the shelf life of cement. Bags of cement raw material is polypropylene resin, mainly for foreign production of polyethylene (PE), mainly for the domestic production of polypropylene (PP), then add some additives, after the heating wire drawing, then weaving, printing and so on, the higher the quality of the cement bag inner lining!

- Q: Which kind of transparent vacuum packing bag 16 wire and 24 wire?

- Suitable for your product packaging, like food packaging, of course, thin, see the product, electronic or hardware thick, anti puncture, of course, does not necessarily have to be very thick, suitable for good

- Q: Printing solvent for food packing bag

- Look at the appearance of the solvent. Should be clear and transparent, if there are cloudy and floating objects, the batch of solvents should be used with caution.

- Q: How can the labels affixed to the bags be removed quickly?

- Labeled plastic products, heating directly in a microwave oven for 2 minutes, and then take it out, the label is no longer sticky, you can easily remove the label with your fingernails, glue also clean up.

- Q: Can the meat with plastic packing bag be pressed directly with a pressure cooker?

- The plastic composite film (bag) products used in food packaging have 8 national and trade standards, and the main standards are divided into physical and mechanical performance indexes and sanitary performance indexes. The indexes of physical and mechanical properties are mainly tensile strength (or tensile strength), elongation, peel strength, heat resistance strength, Charpy impact energy, water vapor permeation amount and the amount of oxygen through the bag, bag, pressure resistance, heat resistance and dielectric performance drop, oil resistance, cold resistance, heat resistance etc.;

- Q: How about the material difference of food packaging bag?

- Reason: PE has better heat sealing property, which is easy to sealPA has better printability and is used in the outer layer to print beautiful picturesPVDC EVOH, good separation performance, prevent oxidation. The film closed light is good, not easy to see the light of the product is appropriate.Specific more professional, no longer introduce one by one

Send your message to us

Date Bag 170g 90cmx120cm PE Material UV treatment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 950000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches