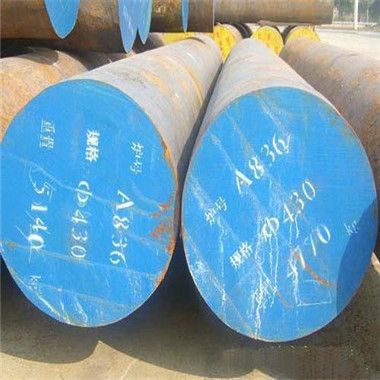

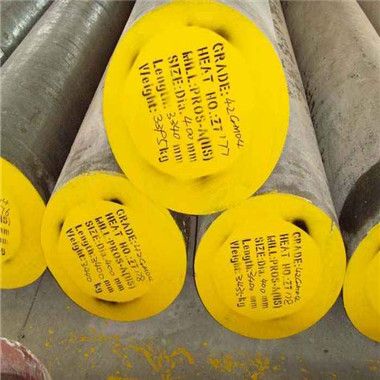

D6 Cold Work Mould Steel Round Bars DIN1.2436

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

D6 Cold Work Mould Steel Round Bars DIN1.2436

AISI D6 tool steel is a high-carbon, high chromium tool steel alloyed with tungsten that is characterized by high compressive strength, high wear resistance, high surface hardness and good hardening stability

Specification of D6 tool steel

1.Diameter:60mm~600mm

2.Length:1-6.5m or as customer's request

The chemical composition of D6 tool steels is outlined in the following table.

| Element | Content (%) |

|---|---|

| Iron, Fe | 83.05 |

| Chromium, Cr | 12.5 |

| Carbon, C | 2.05 |

| Tungsten, W | 1.3 |

| Manganese, Mn | 0.8 |

| Silicon, Si | 0.3 |

Forging

D6 tool steel is heated slowly and uniformly to 700°C (1292°F) and then more rapidly to 900-1050°C (1652-1922°F).

Annealing

D6 tool steel is then annealed at 800-840°C (1472-1544°F) and cooled. Hardness of the steel after annealing will be approximately 225 Brinell.

Stress Relieving

Stresses from D6 tool steel can be eliminated before hardening by heating up to 650-700°C (1202-1292°F), if machining operations have been heavy. The steel is then allowed to cool slowly.

Hardening

D6 steel is pre-heated slowly to 750-800°C (1382-1472°F) and thoroughly soaked. Heating is then continued till the final hardening of 950-980°C (1742-1796°F), followed by air or oil quenching.

Tempering

The steel is heated uniformly and thoroughly at the selected tempering temperature. Double tempering can also be carried out with intermediate cooling to room temperature.

Main applications of D6 tool steels:

Forming tools

Molds for abrasive plastics and ceramics

Long-run press tools

Blanking and shearing tools for hard materials.

- Q: Can steel round bars be heat treated to improve their mechanical properties?

- Steel round bars can undergo heat treatment to enhance their mechanical properties. Heat treatment involves heating the steel to a specific temperature, maintaining it at that temperature for a certain duration, and then cooling it rapidly or slowly. This process can modify the microstructure of the steel, resulting in changes to its hardness, strength, toughness, and other mechanical properties. Various types of heat treatment processes can be applied to steel round bars, depending on the desired outcome. For instance, annealing is a process that entails heating the steel to a specific temperature and subsequently cooling it gradually. This method helps alleviate internal stresses in the steel, enhance its ductility, and facilitate machining. Another commonly used heat treatment process is quenching and tempering. This involves heating the steel to a specific temperature and rapidly cooling it, often by immersing it in an oil or water quenching medium. This swift cooling process helps strengthen the steel, making it more resistant to wear and abrasion. Following quenching, the steel is typically tempered by reheating it to a lower temperature, reducing its brittleness and improving its toughness. In addition to annealing and quenching and tempering, other heat treatment processes such as normalizing, case hardening, and precipitation hardening can also be employed to enhance the mechanical properties of steel round bars. These processes involve different heating and cooling techniques, and are utilized to achieve specific outcomes based on the desired properties of the steel. Overall, heat treatment is a versatile and effective approach for improving the mechanical properties of steel round bars. By carefully controlling the heating and cooling process, significant improvements in hardness, strength, toughness, and other properties can be achieved, rendering the steel suitable for a wide range of applications.

- Q: Difference between cold drawn round steel and round steel

- There are different reasons for the residual stress in hot rolled and cold-rolled steel sections, so the distribution of the residual stresses is also quite different. The residual cold-formed steel section stress distribution is curved, and hot rolled steel or steel welding section on the residual stress distribution is thin.

- Q: Can steel round bars be used for making wire?

- Yes, steel round bars can be used for making wire. Steel round bars can be processed into wire by a process called wire drawing. In this process, the steel round bar is pulled through a series of progressively smaller dies to reduce its diameter until it reaches the desired wire size. This process is commonly used in the manufacturing of various types of wire, including steel wire used in construction, electrical wiring, fencing, and other applications. The steel round bars used for making wire are typically made from carbon steel, which provides the necessary strength and durability for the wire to be used in various applications.

- Q: How do steel round bars compare to other materials like aluminum or titanium?

- Steel round bars have several advantages over other materials like aluminum or titanium. Firstly, steel is known for its exceptional strength and durability. It has a high tensile strength, which means it can withstand heavy loads and resist deformation under stress better than aluminum or titanium. This makes steel round bars an ideal choice for applications that require strong structural support. Additionally, steel has a higher melting point compared to aluminum, making it more suitable for high-temperature environments. It can withstand extreme heat without compromising its strength, making it a preferred choice for applications such as construction, manufacturing, and automotive industries. Another advantage of steel round bars is their cost-effectiveness. Steel is generally more affordable than titanium, making it a more budget-friendly option for various projects. Moreover, steel is readily available and easily sourced, while titanium can be more difficult to obtain and more expensive to manufacture. However, it is important to note that aluminum and titanium also have their own unique benefits. Aluminum is lightweight and has excellent corrosion resistance, making it a preferred material for industries such as aerospace, marine, and automotive. Titanium, on the other hand, is known for its exceptional strength-to-weight ratio and its resistance to corrosion. It is commonly used in applications that require high strength and low weight, such as aircraft components and medical implants. In summary, steel round bars offer unmatched strength, durability, and cost-effectiveness compared to aluminum or titanium. However, the choice of material ultimately depends on the specific requirements of the project, as each material has its own distinct advantages and applications.

- Q: What is the yield strength to tensile strength ratio of a steel round bar?

- The yield strength to tensile strength ratio of a steel round bar is typically around 0.85.

- Q: How do steel round bars perform under fatigue loading?

- High-quality steel round bars generally exhibit excellent performance when subjected to fatigue loading. Fatigue loading refers to the repetitive application of stress or strain on a material, which can eventually cause failure. The outstanding fatigue strength of steel round bars is well-known. This refers to their ability to withstand cyclic loading without developing cracks or failures. This exceptional fatigue strength can be attributed to the inherent properties of steel, including its high strength, ductility, and toughness. During fatigue loading, steel round bars undergo cyclic stress, resulting in alternating tension and compression. Nonetheless, steel possesses a relatively high endurance limit, also known as the fatigue strength coefficient. This limit determines the maximum stress level that the material can endure without failure, even under cyclic loading. Moreover, steel round bars demonstrate commendable resistance to fatigue crack propagation. In the event that a crack does initiate due to cyclic loading, it is less likely to propagate or grow rapidly in comparison to other materials. This can be attributed to the material's ability to absorb energy and redistribute stress, thus impeding crack growth and preventing failure. Nevertheless, it is essential to consider that the performance of steel round bars under fatigue loading can be influenced by various factors. These factors include the specific type and grade of steel utilized, the manufacturing process, surface conditions, and the applied stress or strain levels. Therefore, it is crucial to adhere to industry standards and guidelines when designing and implementing steel round bars to ensure optimal performance and safety under fatigue loading.

- Q: Can steel round bars be used in the automotive industry?

- Indeed, the automotive industry does make use of steel round bars. These bars are frequently employed in various capacities within the industry. Specifically, they are commonly utilized in the fabrication of different components, including axles, drive shafts, suspension parts, and steering components. The reason for their popularity lies in their exceptional attributes, such as high strength, durability, and resistance to wear and tear. These qualities enable them to withstand the rigorous conditions and heavy loads that automotive components are subjected to. Moreover, the ease with which steel round bars can be machined and welded facilitates efficient production and assembly processes in the automotive sector. Consequently, steel round bars are highly regarded as a dependable and cost-effective option for automotive manufacturers, making them a favored material in the industry.

- Q: Can steel round bars be used for making springs?

- Yes, steel round bars can be used for making springs. Steel is a commonly used material for springs due to its strength, durability, and flexibility. Round bars can be machined and shaped into the desired form for different types of springs, making them suitable for various applications.

- Q: What are the different types of steel round bars used in the automotive drivetrain systems?

- There are several types of steel round bars commonly used in automotive drivetrain systems, including alloy steel, carbon steel, and stainless steel. These bars are chosen based on their specific properties and characteristics, such as strength, durability, and resistance to corrosion. The selection of the type of steel round bar depends on the specific application and requirements of the drivetrain system.

- Q: What are the applications of steel round bars?

- Steel round bars have a wide range of applications across various industries due to their inherent strength, durability, and versatility. Some of the key applications of steel round bars include: 1. Construction: Steel round bars are extensively used in the construction industry for various structural purposes. They are commonly used for building columns, beams, and frames due to their high strength-to-weight ratio, which ensures stability and safety in construction projects. 2. Manufacturing: Steel round bars are widely used in the manufacturing sector for fabricating various components and machinery. They are commonly employed in the production of gears, shafts, axles, and other machine parts that require high strength and precision. 3. Automotive industry: Steel round bars find significant applications in the automotive industry. They are used in the manufacturing of crankshafts, connecting rods, suspension components, and many other parts, providing strength and reliability to vehicles. 4. Oil and gas industry: In the oil and gas sector, steel round bars are used for manufacturing drill bits, valves, pipes, and other equipment that are exposed to harsh environmental conditions and require high strength and corrosion resistance. 5. Aerospace industry: Steel round bars are essential in the aerospace industry due to their high strength and lightweight properties. They are used in the production of aircraft components, such as landing gear, engine parts, and structural components. 6. Shipbuilding: Steel round bars are commonly used in shipbuilding due to their excellent strength and corrosion resistance. They are used in the construction of ship frames, hulls, and other critical components that require durability and resistance to harsh marine environments. 7. Infrastructure projects: Steel round bars are extensively used in infrastructure projects, such as bridges, tunnels, and railways. They provide the necessary strength and stability required for supporting heavy loads and ensuring the structural integrity of these projects. 8. Furniture and interior design: Steel round bars are also used in the furniture and interior design industry. They are commonly employed in the construction of chairs, tables, shelves, and other furniture pieces due to their sleek appearance, durability, and easy formability. Overall, steel round bars have a wide range of applications in various industries, contributing to the development of robust and reliable structures, machinery, and equipment.

Send your message to us

D6 Cold Work Mould Steel Round Bars DIN1.2436

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords