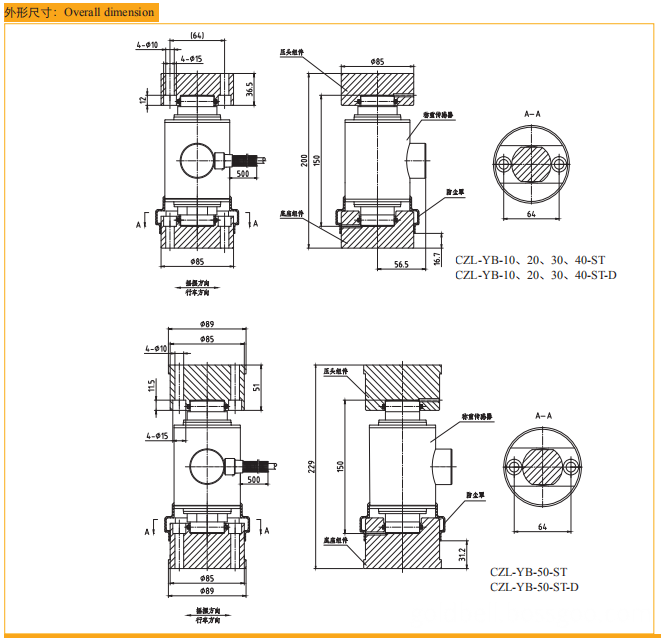

CZL-YB Type Analog Column Type Load Cell

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CZL-YB type load cell is full sealing double ball head column type structure. It uses stainless steel material, and has good automatic center adjusting and anti-rotation function, good dynamic response, strong anti-overload capacity, uses metal diaphragm welding sealing technology, its waterproof and dust proof capacity reaches the requirements of IP68 and IP69K level. It can suit adverse working environment, and has advantages such as high accuracy, convenient installation and repair and reliable operation. It has capacity from 10t to 50t, and can be used for producing various scales such as digital electronic truck scale, dynamic railway scale and large capacity hopper scale. Its explosion proof label is Exia II CT6Ga; ExiaD20T85. CZL-YB-××-ST-D type load cell is installed with metal net anti-mouse bite double shield cable, and has anti-mouse bite function.double shield cable, and has anti-mouse bite function.

- Q: Now do the experiment, build your own test platform and buy 4 pressure sensors, I am responsible for how to collect the experimental data But I don't understand very well, all ask everybody.Signal amplifier, analog signal conversion, how to connect to the computerPS: what kind of software acquisition is used in the general data collection?

- You'd better add a module in the middle...Data acquisition, communication, host computer

- Q: The product is a ABB ACS355 transducer that is fed back to a 4-20MA output pressure sensor that is controlled by an instrument and made automatically by an PID regulator

- To do the closed-loop control of the inverter, to enter the settings menu, set the type of input signal, the upper limit of the range, the lower limit, the control value and many other parameters, to carefully look at the instructions will be clear.

- Q: Is there a heat sensor on the bus? What's the function?

- There must be a heat sensor on the car, mainly to test the cooling water temperature, so as to judge the temperature of the engine. Because the normal operation of the engine, only in a suitable temperature range can be carried out.

- Q: And sometimes the pressure doesn't go. What's the matter? The air compressor only took a year and a half.

- 1. For instrument problems, check the following locations:Inlet valve failure;? the minimum pressure valve is jammed and needs to be cleaned, readjusted or replaced;? the pressure switch setting is too low (should not);? pressure sensor failure;? pressure gauge failure ? pressure switch fault;? pressure sensor or gauge input hose leaks. ,TwoUsually pay attention to maintenance work, regular inspection of the replacement of air filters, oil filters, and a variety of instrument valves (maintenance work reference random manual)

- Q: How many parts does the pressure sensor consist of?

- Signal processing sectionConvert physical quantities into electrical signals

- Q: The automobile intake pressure sensor is out of order. What effect does it have?

- Some car pressure sensor bad won't get hit some bad taxi and car idling instability to gas mixture get underpowered or thin because ECU is based on the intake pressure sensor crankshaft position sensor for coolant temperature sensor signal control three fuel inlet pressure sensor is broken ECU have not accepted the signal of intake air or received is not accurate so there will be some of the above fault symptom; not a car, lights, engine code ECU, data storage, misalignment and other symptoms.Diagnosis; consultation with a decoder.Methods according to the consultation results, the necessary investigation, adjustment, maintenance, code repetition and test run shall be carried out in sequence, according to the order.Summary: on time to protect the car, improve performance, low carbon environmental protection, identify problems, timely investigation, eliminate hidden dangers and ensure safety.

- Q: The basic principle of strain gauge pressure sensor

- Strain gauge pressure sensor straingauge, pressure, transducerThe working principle of the resistance strain gaugeThe working principle of the metal resistance strain gauge is that the resistance of the strain is changed on the base material. The resistance changes with the mechanical deformation, which is commonly called the resistance strain effect. The resistance of a metal conductor can be expressed in the lower order:Type: resistivity - metal conductor (. Cm2/m)S - cross sectional area of conductor (cm2)L - conductor length (m)We use metal wire strain resistance as an example, when the metal wire under the action of external force, its length and cross-sectional area will change from the type of it is easy to see that the resistance value is changed, if the wire under the action of external force and elongation, the increase in the length and cross-sectional area of reduced resistance value will increase. When the wire is compressed by external force, the length decreases, the cross section increases, and the resistance decreases. As long as the change in the resistance (usually measuring the voltage at both ends of the resistor), the strain of the strain wire will be obtained

- Q: For two wire pressure sensors, two wires are used to connect the power supply. How does the PLC collect its analog signals from the 4-20mA?

- For example, capacitive pressure sensors are passed through the capacitor - current linear conversion into the PLC, and the transformation part of the circuit power consumption is very small, negligible, so that you can save a line!

- Q: Automobile tire pressure sensor principle is how to work ah? Some cars don't have sensors installed in the tire valve. How do you detect low pressure? How do you monitor and alarm automatically?

- Detection principle1 、 direct tire pressure monitoringDirect tire pressure monitoring device is the use of pressure sensors installed in each tire to directly measure the tire pressure, using a wireless transmitter will send information from the tire to the central receiver module, and then the tire pressure data display. When the tire pressure is too low or leak, the system will alarm automatically.2 、 indirect tire pressure monitoringThe principle of indirect tire pressure monitoring is that when the pressure of a tire is lowered, the weight of the vehicle will reduce the rolling radius of the wheel, causing its speed to be faster than that of other wheels. By comparing the speed difference between the tires, to achieve the purpose of monitoring tire pressure. The indirect tire warning system actually monitors the air pressure by calculating the tire rolling radius.There are two main solutions to the tire pressure monitoring system, the direct system and the indirect system.Direct tire pressure monitoring system is the direct measurement of tire pressure by the pressure sensor is installed in every tire in, and the tire pressure display and monitoring, when the tire pressure is too low or when there is leakage, the system will automatically alarm.The indirect tire pressure monitoring system uses the wheel speed sensor of the automobile ABS system to compare the speed difference between the tires to achieve the purpose of monitoring the tire pressure:1, can not display accurate instantaneous pressure value of each tire;2, the same axle or the same side of the wheel or all tire pressure drop at the same time, can not alarm;3, can not take into account both speed, detection accuracy and other factors.

- Q: Is the Fawkes intake pressure sensor and the intake air temperature sensor a sensor?

- Look, how many lines are there? Three words should be together...Some machines are separate...Yes, togetherHow many lines are there?...

Send your message to us

CZL-YB Type Analog Column Type Load Cell

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords