B-XG Type Parallel Beam Structure Load Cell

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

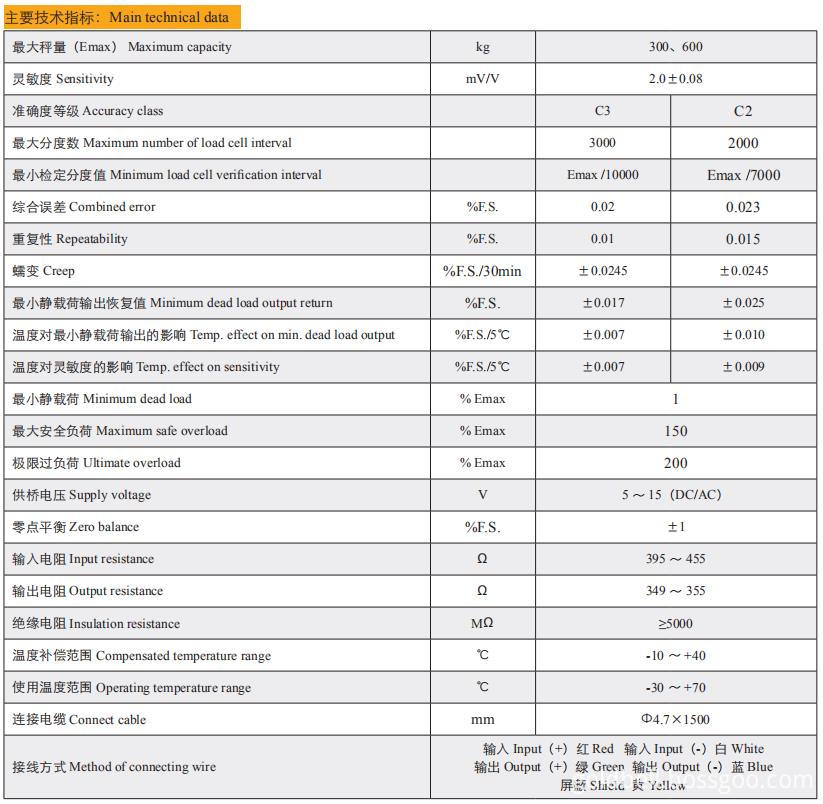

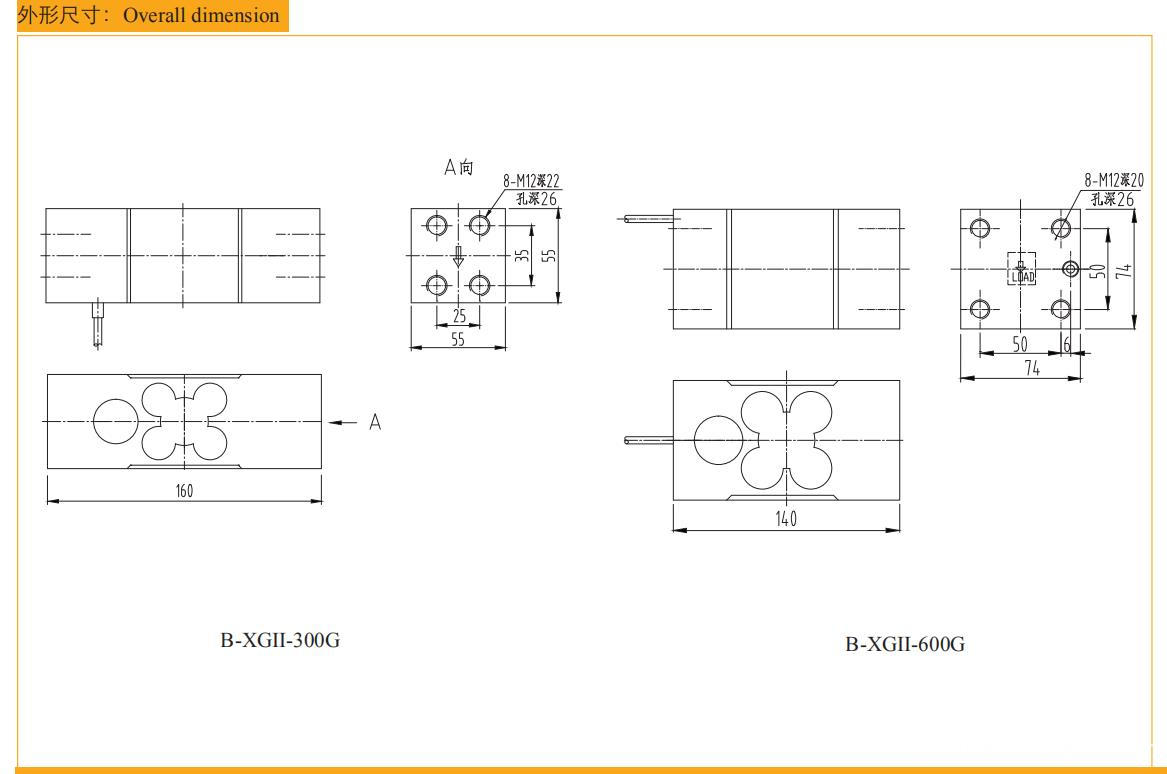

B-XG II -××G type load cell (made of alloy steel) is double parallel beam type with small size. The load cell (made of aluminum alloy) is double holed parallel beam type. It is through technology treatment of temperature compensation and adjusting four-corner error. It has low height and small size. It has been conducted four corners adjustment, has good anti-tilting-load, easily for installation and use.

The load cell has high quality and performance, long-term stability and safety. Our company uses the load cell in own platform scale and bench scale, and exports the load cell to various countries such as South Africa, Thailand, Indonesia and Phillipine.

It is suited to produce electronic price computing scale, electronic counter scale, electronic platform scale and other electric scales with small capacities.

The load cell has protection grade specified as IP67. It is able to be used in explosive dangerous circumstance, the explosion-proof symbol is Exia II CT6Ga; ExiaD20T85.

,

- Q: Can I use a pressure sensor on the transformer?

- The transformer is not familiar with me, I am a sensor, you just need to determine whether the transformer work in the consideration of pressure factors, whether or not the side pressure signal, you can know whether or not to use a pressure sensor.

- Q: The pressure sensor passes, 4-20MA signal how programming can use it.

- You need to have an acquisition module that converts the analog to digital.As some conversion module ART-3048F or Advantech can.

- Q: Is the pressure sensor directly connected to the 24V at both ends damaging?

- This looks at what you are, the direct sensor (the output of the MV signal), or the output of the standard voltage product, and there is a need to see how much your range is

- Q: The Audi A6 intake pressure sensors are installed there

- The intake pressure sensor is mounted behind the throttle valve. Audi 2.4, 2.8, 3.2 and the new 2.5 displacement are installed in the throttle.

- Q: How does the pressure sensor control the flow of the pump?

- The pressure sensor provides pressure information feedback to control the pump pressure and can not control the flow directly

- Q: What are the pressure sensors for?

- By means of signals, the pressure is converted to digital display, visualized on the computer, so that it is easier to adjust the pressure

- Q: Design method and procedure of flat diaphragm piezoresistive pressure sensor

- Diaphragm piezoresistive pressure transducer.. I give,

- Q: I want to find a pressure sensor driver on the steering wheel grip (preferably can be transferred to the steering wheel, internal) should use which kinds of sensors? How to design? Please understand people feel free, thank you! The answer is acceptable, I add points.

- The driver's grip on the steering wheelIt's going to change. I think it's related to the degree of stress the driver hasIf you want to test, the driver will have an uncomfortable feelingIt may be difficultWhat do you want to know about this?

- Q: Does the pressure sensor have to work with an exciting power source?

- The pressure sensor requires a power supply. Pressure sensors generally have two wire system and three wire system, the two-wire power supply can be provided by instrument or module, and the three wire system can also be supplied by switching power supply or regulated power supply. The work principle and function are same.

- Q: The pressure sensor changes the pressure signal into a current signal, and the received pressure signal remains constant, while the actual pressure is constantly changing

- The current that reflects the magnitude of the pressure should be at 4~20mA. Is your current within this range? Beyond this range, be sure your sensor is out of order.If the current is fixed within this range, check that the pressure is applied to the sensor diaphragm Have you ever been blocked? If these are normal, you still think the sensor is broken.

Send your message to us

B-XG Type Parallel Beam Structure Load Cell

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords