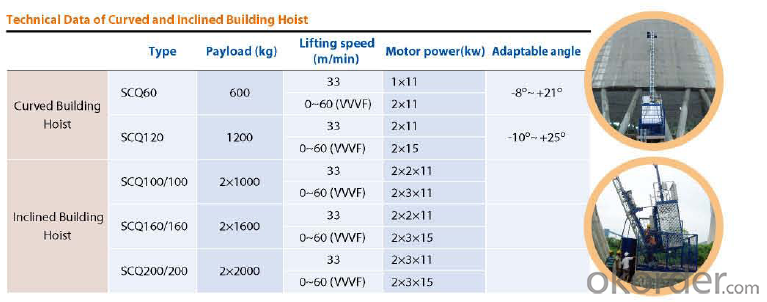

Curved and Inclined Building Hoist for Power Plant

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Description:

The general building hoist manufactured by our company have the features as good quality, long life, wide application range and convenient for maintenance, the gering adopts imported bearing, enameled cable, and oil seal, the electric parts adopt products from world renowned manufactures such as Schneider, Siemens, and LG, the racks and pinion adopts special material and heat-treatment technique, which prolong the life of these parts. The steel structure uses quality steel from famous domestic manufacturers, the surface of the structure can apply paint-spray, Parkerizing baking finish or hot galvanizing processing according to users requirements, the cage can be produced and decorated by aluminum molded board, punched-plate or figured aluminum board.

Feature:

1. The recommended cage dimension(LXWXH):2.0X1.0X2.5, 2.5X1.0X2.5, 2.5X1.3X2.5, 3.0X1.5X2.5, 3.2X1.5X2.5, 3.8X1.5X2.5, 4.0X1.5X2.5, 4.2X1.5X2.5 etc, we can also manufacture cages of other size according to the user.

2. The cage and the door material can be aluminum molded board, punched-plate, figured aluminum board or other type according to your requirements.

3. The mast and the tie-in surface can adopt paint-spray, or hot galvanizeing processing.

Image

FAQ:

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance & exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: Is it possible to utilize a building hoist for lifting materials during demolition projects?

- <p>While a building hoist is typically designed for construction purposes to lift materials and personnel, it is not advisable to use it for demolition work. Demolition involves hazardous conditions with falling debris and unstable structures, which can compromise the safety and integrity of the hoist. Instead, specialized equipment like wrecking balls, hydraulic shears, and cranes are more suitable for demolition tasks. These are engineered to handle the heavy loads and unpredictable conditions associated with breaking down structures safely.</p>

- Q: This question seeks to understand the benefits and drawbacks associated with the use of hydraulic building hoists in construction.

- <p>Hydraulic building hoists offer several advantages, including high lifting capacity, smooth and controlled lifting, and lower maintenance costs due to fewer moving parts. They are also energy-efficient and can be easily integrated into existing systems. However, they have some disadvantages. For instance, they can be more expensive to purchase initially compared to other hoist types. Additionally, they may require more space for installation and can be sensitive to extreme temperatures, which might affect performance. Lastly, hydraulic systems can be prone to leaks and require regular fluid checks and maintenance to prevent system failure.</p>

- Q: Explain the distinctions between electric and hydraulic building hoists, focusing on their mechanisms, efficiency, and applications.

- <p>Electric building hoists use electric motors to drive the hoisting mechanism, which can be more efficient and require less maintenance than hydraulic systems. They are often quieter, have fewer leaks, and can be more precise in their operation. Hydraulic building hoists, on the other hand, use hydraulic pressure to lift loads. They can handle heavier loads and are often used in situations where there is no electricity available. However, they may require more maintenance due to potential leaks and can be less precise in their movements.</p>

- Q: Is it possible to use personal components to fix a malfunctioning building hoist?

- <p>While it might be tempting to use your own parts to repair a malfunctioning building hoist, it is generally not recommended. Building hoists are complex pieces of machinery that require specific components to function safely and efficiently. Using non-standard parts can lead to further damage, safety hazards, and may void any warranty on the hoist. It's crucial to use parts that meet the manufacturer's specifications to ensure the hoist operates correctly and safely. Always consult with a professional or the manufacturer for repair advice and parts.</p>

- Q: What are the alternative uses of a building hoist besides construction?

- <p>Yes, building hoists can be used for other purposes beyond construction. They can be utilized in various industries for material handling, such as in warehouses for moving goods, in factories for lifting machinery, and in maintenance for accessing high areas. Additionally, building hoists can be employed in emergency services for rescue operations, especially in high-rise buildings. They are also used in special events for setting up stages and equipment. The versatility of building hoists makes them a valuable tool in many different scenarios where vertical transportation of materials or personnel is required.</p>

- Q: The construction elevator can only go up can't come down what happened

- It hasn't risen yet, how it has fallen! Is it a brain teaser?

- Q: What are the essential maintenance tasks and checks required to keep a hydraulic building hoist in good working condition?

- <p>Regular maintenance of a hydraulic building hoist is crucial for safety and efficiency. Key requirements include inspecting and lubricating moving parts, checking for leaks in hydraulic lines and seals, ensuring the hoist's load limit is not exceeded, and verifying the operation of safety devices like limit switches and emergency stops. Additionally, the hydraulic fluid should be checked for contamination and changed as needed, typically every 1000 hours of operation or annually. The electrical system should be inspected for any damage or wear, and all controls should be tested for proper functionality. A thorough inspection by a qualified technician is recommended at least once a year to ensure all components are in compliance with safety standards.</p>

- Q: This question asks for a comparison of the pros and cons associated with the use of building hoists in construction projects.

- <p>Building hoists offer several advantages, including increased efficiency in material transportation, reduced labor costs, and improved safety by minimizing the need for manual handling at height. They can also be used for personnel transport, enhancing site accessibility. However, there are disadvantages such as high initial costs, the need for regular maintenance and inspection, and potential downtime due to mechanical issues. Additionally, they require space for installation and can obstruct views or access during operation. Safety concerns also arise if not properly managed, as accidents can occur due to operator error or mechanical failure.</p>

- Q: This question asks about the precautions and safety protocols that should be followed when using lifting equipment in construction projects.

- <p>Safety measures for using lifting equipment in construction work include regular inspections and maintenance of the equipment, ensuring all safety features are in place and functioning correctly. Operators must be trained and certified for the specific type of lifting equipment they are using. Load limits should never be exceeded, and all loads must be secured properly. Safe operating procedures should be followed, such as not lifting loads over people and maintaining a safe distance from power lines. Personal protective equipment (PPE) must be worn by operators and workers in the vicinity. Emergency procedures should be established and communicated to all workers. Regular safety briefings and training sessions should be conducted to keep safety at the forefront of all operations.</p>

- Q: How does the construction elevator add up

- You can use a ready-made high-altitude operating platform and a high-altitude working platform

Send your message to us

Curved and Inclined Building Hoist for Power Plant

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords