Construction Hoist Counterweight High Qualified

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Construction Hoist Description

Feature: Construction Hoist Condition: New Application: Construction

Payload(kg):2700 Lifting Speed(m/min):0-33 Motor Power(kw): 2*15

Safety Device: SAJ50-1.2 Cage: Single Counterweight: Yes

Certification: CE,ISO Place of Origin: China(Mainland) Model Number: Type:SCD270

Packaging & Delivery of Construction Hoist

Packaging Detail: Nude package Delivery Detail: 25-30days

Main Parts of Construction Hoist

● The gearing adopts imported bearing, enameled cable, and oil seal.

● The electric parts adopt products from world renowned manufactures such as Schneider, Siemens, and LG.

● The racks and pinion adopts special material and heat-treatment technique, which prolong the life of these parts.

● The steel structure uses quality steel from famous domestic manufactures.

● The surface of the structure can apply paint-spray, parkerozing baking finish or hot galvanizing processing according

to users requirements,

● The cage can be produced and decorated by aluminum molded board, punched-plate or figured aluminm board.

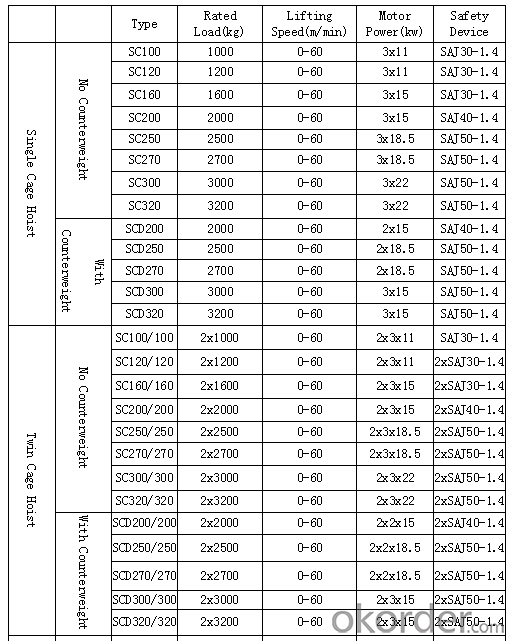

Construction Hoist Specifiction

FAQ of Construction Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance

& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: Is it possible to utilize a building hoist for lifting materials during demolition projects?

- <p>While a building hoist is typically designed for construction purposes to lift materials and personnel, it is not advisable to use it for demolition work. Demolition involves hazardous conditions with falling debris and unstable structures, which can compromise the safety and integrity of the hoist. Instead, specialized equipment like wrecking balls, hydraulic shears, and cranes are more suitable for demolition tasks. These are engineered to handle the heavy loads and unpredictable conditions associated with breaking down structures safely.</p>

- Q: This question asks for a description of the process of operating a building hoist using a remote control system.

- <p>To use a remote control system for a building hoist, first ensure that the hoist is properly installed and inspected for safety. Turn on the hoist's power supply and ensure the remote control is synced with the hoist. Familiarize yourself with the control panel, which typically includes buttons for up, down, stop, and emergency stop. Operate the hoist by pressing the up or down buttons to lift or lower the load. Always monitor the load's movement and communicate with workers on site. Use the stop button to halt the hoist if needed, and the emergency stop button in case of an immediate hazard. Regularly check the hoist's operation and maintain the remote control system to ensure smooth and safe operation.</p>

- Q: This question asks for the method to determine the maximum weight an electric-hydraulic lifting system can handle.

- <p>To calculate the maximum load capacity of an electric-hydraulic lifting system, you need to consider several factors: the hydraulic cylinder's piston area, the pressure rating of the hydraulic system, and the mechanical strength of the system components. The formula to calculate the maximum load (P) is P = A * P, where A is the area of the piston in square inches or square meters, and P is the pressure in pounds per square inch (psi) or Pascals (Pa). Ensure to convert units if necessary. Additionally, account for safety factors and the mechanical limits of the system to determine the practical maximum load that the system can safely lift without risk of failure.</p>

- Q: This question asks for methods to protect lifting equipment from damage while it is being transported or stored.

- <p>To prevent damage to lifting equipment during transportation or storage, follow these guidelines: 1. Use protective covers or wraps to shield equipment from environmental elements. 2. Securely fasten equipment to prevent movement during transit. 3. Store equipment in a dry, clean area to avoid rust and dirt accumulation. 4. Regularly inspect equipment for signs of wear or damage before and after use. 5. Follow the manufacturer's guidelines for weight limits and proper handling. 6. Use padding or cushioning materials to protect equipment from impacts. 7. Ensure that all parts are properly lubricated to prevent rust and facilitate smooth operation. By adhering to these practices, you can significantly reduce the risk of damage to lifting equipment.</p>

- Q: This question asks whether it is safe to operate a building hoist in adverse weather conditions such as wind and rain.

- <p>The use of a building hoist in windy or rainy weather is generally not recommended due to safety concerns. Wind can cause instability and swaying of the hoist, while rain can lead to slippery conditions and electrical hazards. Most hoist manufacturers and safety guidelines advise against operating hoists in such conditions. However, if absolutely necessary, it should be done with extreme caution, following specific safety protocols, and ensuring all necessary weatherproofing and stability measures are in place. Always consult the manufacturer's guidelines and local regulations before operating a hoist in adverse weather.</p>

- Q: What precautions should be taken when using manual lifting equipment to ensure safety?

- <p>Safety measures for using manual lifting devices include inspecting equipment for damage before use, ensuring the load is within the device's weight capacity, using proper lifting techniques, maintaining a clear path for lifting, and securing the load to prevent shifting. Always wear appropriate personal protective equipment, such as gloves and safety shoes. Never exceed the rated capacity of the lifting device, and avoid sudden or jerky movements that could cause loss of control. Regular maintenance and training on safe lifting practices are also crucial to prevent accidents.</p>

- Q: For example, what records do you want to have a third party monitoring?

- After the construction elevator overhaul, the contents of the inspection and acceptance inspection shall be inspected; In the use of elevators, the contents of the regular inspection shall be conducted once a year in accordance with the provisions of the regulations.

- Q: This question asks for the detailed specifications and dimensions of a building hoist, which is a type of construction equipment used to lift materials.

- <p>The specifications and measurements of a building hoist can vary significantly depending on the model and manufacturer. Generally, a building hoist (also known as a construction hoist or material hoist) is characterized by its load capacity, which can range from 500 kg to several tons. The height of the hoist is determined by the number of floors it serves, typically measured in meters. The width and depth are usually around 1.5 to 2 meters, and the speed can vary from 24 to 60 meters per minute. The power requirement is often between 3 to 7.5 kW. Safety features like overload protection, emergency stop, and limit switches are also standard. For precise specifications, it's essential to consult the manufacturer's data sheet for the specific model in question.</p>

- Q: Is it permissible to use a building hoist for lifting people or animals?

- <p>No, building hoists are not designed for lifting people or animals. They are specifically engineered for the transportation of materials and construction equipment. Using a building hoist for this purpose is dangerous and can lead to accidents. It is essential to adhere to safety regulations and use appropriate equipment for lifting people or animals to ensure their safety and comply with legal standards.</p>

- Q: What is the purpose of a building hoist and can it be utilized for lifting heavy objects that cannot be manually lifted?

- <p>Yes, building hoists are specifically designed to lift heavy objects that are beyond the capacity of manual lifting. They are essential in construction sites for moving materials such as bricks, cement, and steel beams to various levels of a building. Building hoists are engineered to handle significant weight and ensure the safe and efficient transport of materials, reducing the risk of injury and improving productivity on construction sites.</p>

Send your message to us

Construction Hoist Counterweight High Qualified

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords