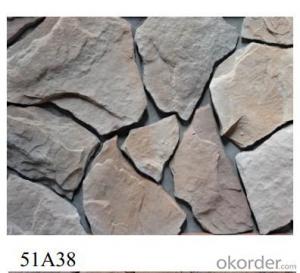

Culture stone BA 019

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

We have:

Mushroom stone series

Hometown reef series

Scattered stone series

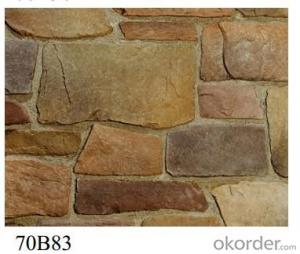

Reef rock stone series

Nangai reef series

Water washed stone series

Mixed stone series

Antique brick series

It can be used by outdoor or indoor building materials

Delivery time is 20 days after you confirm the order

TT or LC payment is available for us.

Material: Reef rock stone series

Size can be adjusted according to customers' requirements.

- Q: Decoration commonly used plate brand?

- Top 10 brands of board-off woodworking board Hebei Tengfei Wood Co., Ltd. is a private joint-stock enterprises, which was established in 1996, more than 800 employees, mainly engaged in sheet, multilayer, Glulam R & D and production. Plate top ten brands of Peng Hong. Dalian Peng Hong Wood Co., Ltd. was founded in 1997, is China's wood-based panel industry leader. The company's comprehensive production capacity and product sales in the domestic wood-based panel manufacturing industry in a leading position in the domestic market enjoyed a high reputation. Top 10 brands of Albert. Guangzhou Wei Zheng Wood Products Co., Ltd. was established in 1996, is a professional production of "Wei-licensing" green plywood of wood products large enterprises. The company has been committed to improving the human living environment, to create a harmonious home, tree industry standards, has made brilliant achievements.

- Q: What is the smart sheet?

- Smart sheet can be interpreted as intelligent sheet metal, King coconut latest release of intelligent paint-free board is smart sheet 1, intelligent simulation Using a selection of 5A-class model to ensure that each piece of intelligent paint-free board standards the best; Mianqi the surface of the impregnated film coated paper, using a digital scanning, digital imaging, digital printing technology to ensure that the finished color texture clear and realistic. 2, intelligent security Joined the UV hidden map recognition, digital layer security, intelligent information reading, physical visual security of the four recognition system to ensure that every user can rest assured that the use of King coconut products. 3, intelligent customization Choose the most representative, to undertake China's thousands of years of wood culture of natural precious wood varieties, and synchronized supporting the decorative lines and hardware, customized for consumers to enjoy the private sector, for the vast number of consumers to create a multi-functional intelligent home Living space, its beauty is no less than a variety of finished furniture. 4, intelligent experience: Through the Tablet PC, mobile phones, computers and other tools to show a variety of styles and style effects, to eliminate the consumer in the selection of the concerns, bring the sheet industry in the unprecedented ease and convenience.

- Q: Black box plate glasses for what kind of person

- If the election is more affinity Recommend the kind of color plate Black is the main color, in the edge of the box through the other colors Bright pink and bright blue are good But also a little round of the black box Not the kind of side (some formal) Or when to pick the time to see There is the kind of wrapping a little more upset That kind of wear will be very cute

- Q: Density board and Orson board difference

- Densboard (English: Medium Density Fiberboard (MDF)), also known as fibreboard, is made of wood fiber or other plant fiber as raw material, urea resin or other suitable adhesive made of artificial plate. According to their density, divided into high density board, MDF, low density board. Dust board due to the soft impact resistance, but also easy to reprocess, in foreign countries is a good material for the production of furniture, but because the country on the high density board standards than the international standard several times lower, so the density board in China, the use of quality Still need to be improved. Orson board refers to: Aosen card in the high density board. Mainly used to strengthen the floor of the substrate, but also for the furniture industry.

- Q: How to identify the millennium boat plate

- It is not what you do, belong to the cultural relics, and need archaeologists identification.

- Q: What plate to do the best white oil effect

- White paint in two kinds 1 white mixed with 3MM thick Austrian Song board is the most appropriate 2 white is the best paint is the next song with white water white or white maple oak and maple texture to do no water Willow effect no matter what time the material as long as you can match the effect of glazed tile is not because It was thousands of years ago and was eliminated

- Q: Plate and line joints at the crack causes, with morning sun water paint can improve it

- I can use the morning sun water-based wood paint, like a wooden furniture clothes, not only cleverly cover up the wood surface of the insects, knots, color and other defects, but also to highlight the beautiful texture of wood, while Play the role of protection of wood. Recommend you try, very safe

- Q: Now I'm going to calculate a display panel for the material sheet, and I'm ready to calculate the square of the plate! The data is: length [1200MM] width of [750MM] thickness of [480MM] material name is [white light paint] how to calculate how many squares to use it? Jaya! Say it! I put the remaining 5 points all to You say that one of them.

- Is it not your cabinet High: 1200 Width: 750 Depth: 480? The cabinet you have to open. There are two side panels, a roof a floor, a backplane, but you have to know there is no solid and activities Plywood. According to your size: 1.2 * 0.48 * 2 = 1.152 0.75 * 0.48 = 0.72 1.2 * 0.75 = 0.9 Probably square: 2.78. Just a mao count, there is a board where I have not subtracted.

- Q: With self-tapping or what ,,,, solve, six meters wide and two meters of the door can be installed on the ground in the installation of the door?

- Are generally used for self-tapping screws, for relatively heavy and relatively large load, you can use ordinary bolts, heavier are to use high-strength bolts to link. You say six meters wide and two meters, to use a few bolts, if necessary, with ordinary bolts to fix.

- Q: Wardrobe to choose how thick the plate

- Wardrobe sliding door generally choose 15mm, 16mm, 18mm of the majority of the plate.

Send your message to us

Culture stone BA 019

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords