Corundum Brick - Comprehensive CNBM Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1) Sintered alumina based

2) Vibrated & mechanical pressing

3) Used for low carbon & ultra low carbon steel ladle.

4) ISO&SGS

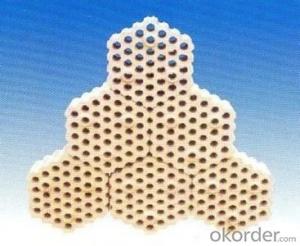

Free Carbon Corundum Spinel Carbon Brick for Refining Ladles

1. Anti erosion, anti stripping, high strength, low thermal conductivity

2. Controlled size as your requirments;

3. ISO&SGS, approved by Sinosteel Luoyang Institute of Refractories Research Co.,Ltd. ;

4. Factory direct price.

Description of Free Crbon Corundum Spinel Carbon Brick

YH-WT series Free Carbon Corundum Spinel Carbon Brick is new furnace lining material developed by our company for the low carbon or ultra low carbon steel. It is shaped by vibration or machine power by using sintered corundum as main material and special chemical raw materials for matrix strengthening. It has the advantages of anti erosion, anti stripping, high strength and low thermal conductivity. It is applicable to the ladle bottom, wall parts, etc, especially for the applications of the low carbon or ultra low carbon steel.

Main Chemical Compositions and Physical Properties of Corundum Spinel Carbon Brick

| Items | Chemical Compositions(%) | Bulk Density(g/cm3) | Apparent Porosity(%) | Compressive Strength(Mpa) | Linear Change(%) | High Temperature Flexural Strength(Mpa) | ||

| Standard | Al2O3 | MgO | C | (110℃*24h) | 155℃*3h | 1000℃*3h | ||

| ≥88 | ≥2.0 | ≤2.0 | ≥2.9 | ≤20 | ≥30 | -0.2~+0.8% | ≥5.0 | |

- Q: Application of electric high temperature regulating valve?

- Acid refractory with silicon oxide (SiO2) as the main ingredient, commonly used are silica brick and clay. Brick is siliceous products containing more than 93% SiO2, the use of raw materials with silica, silica and other waste. The silica acid slag erosion ability is strong, but vulnerable to the erosion of basic slag, its softening temperature is very high, close to the fire, the volume does not shrink after repeated burning, or even a slight swelling, but the thermal shock stability. The brick is mainly used for thermal equipment of coke oven, glass furnace, furnace and other acidic silica brick, according to the physicochemical indexes and SiO2 content can be divided into several levels, mainly used in glass furnace and coke oven silica brick for two categories. Clay brick with refractory clay or bauxite clinker as main raw material, containing 30% to 46% of alumina, refractory degrees 1580 to 1770 DEG C, weak acid refractory material, heat shock resistance, resistance to acid slag, widely used in refractory clay brick clay as main raw material is called common clay brick that made pyrojewel clinker as the main raw material, the porosity in the clay brick below 17% is called low porosity clay brick. Two kinds of clay bricks are divided into several grades according to the physical and chemical indexes. The price difference between the ordinary clay bricks and the low porosity clay bricks is great.

- Q: How much is a thermal brick?

- If you really want to buy thermal insulation brick, do not simply look at the price, but also to consider the quality of the product. (a piece of brick in the market basically in 6 yuan, if there is a floating price if it is because of the size of the insulation brick or distance, but floating slightly.)

- Q: How much is a refractory brick?

- There are many kinds of refractory bricks, you have to look at what is material, the material is not the same, the price is not the same, clay brick is the cheapest, probably hundreds of dollars a ton, and corundum brick a ton of several money, silicon carbide, silicon nitride, and more expensive. And this thing is generally on t sell, the price is by a single block after conversion.

- Q: What equipment is used for producing diamond blanks? How much is the investment?

- Plus all the cables fifty thousand. Steel 10000 yuan. Corundum bricks; insulating bricks; clay bricks, these three require more than ten thousand. The electrode is about one hundred thousand. It's just an investment in an electric furnace. Together with the rear section processing and raw materials need hundreds of thousands of.

- Q: How to improve the induction furnace campaign, from the promotion of refractory life start

- Select suitable insulation materials, such as polycrystalline facing blocks and ceramic fiber modules, depending on the service temperature

- Q: What is the hardness of corundum refractory bricks?

- Such as zirconium corundum refractory brick, chrome corundum refractory titanium corundum refractory brick.

- Q: High temperature refractory material?

- Acid refractory with silicon oxide (SiO2) as the main ingredient, commonly used are silica brick and clay brick is siliceous. Products containing more than 93% SiO2, the use of raw materials with silica, silica and other waste brick. Acid slag erosion ability is strong, but vulnerable to the erosion of basic slag, its softening temperature is very high that is close to the refractory, the volume does not shrink after repeated burning, or even a slight swelling, but the thermal shock stability. Silica is mainly used for thermal equipment of coke oven, glass furnace, furnace and other acidic silica brick, according to the physicochemical indexes and SiO2 content can be divided into several levels, mainly brick for glass furnaces and used for coke oven two kinds of brick clay brick. With refractory clay or bauxite clinker as main raw material, containing 30% to 46% of alumina, refractory degrees 1580 to 1770 DEG C, weak acid refractory material, heat shock resistance, resistance to acid slag, wide application Pan, clay brick with refractory clay as main raw material is called ordinary clay brick, made with bauxite clinker as main raw material, the porosity in the clay brick below 17% is called low porosity clay brick. Two kinds of clay brick and according to the physicochemical indexes which were divided into several grades, the price difference between ordinary clay brick and low porosity clay brick greatly.

- Q: How do corundum bricks bind?

- High temperature bonding clay can be used for bonding masonry

- Q: What problems should we pay attention to in the use of fused zirconia corundum brick (fused zirconia corundum brick) in glass furnace?

- Casting, casting mouth often appear shrinkage, brick porosity more, the density is lower, so in the brick wall of glass melting, the shrinkage in the kiln direction, if the nozzle outward, when the brick to erosion is very thin, can cause leakage of liquid glass accident. When the flame space is used in the upper part of the bath furnace, the service life is long, and the glass liquid problem can not happen, so the casting mouth is used outwards, and the service life is prolonged.

- Q: What can zirconium sponge do for those industries?

- Uses: aerospace, military, nuclear reactions, atomic energy, and metal superhard materials, the manufacture of bulletproof alloy steel, can also be used in the reactor uranium fuel coating alloy; zirconium at high temperatures easy to launch electronicProduct characteristics: zirconium metal has very strong corrosion resistance, ultra high hardness and strength

Send your message to us

Corundum Brick - Comprehensive CNBM Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords