Corundum Alumina Chrome Brick CNBM Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Index | JZGK-N | JZGK-S | |||

Standard | Typical | Standard | Typical | ||

Bulk Density,g/cm3 | ≥ 3.30 | 3.32 | ≥ 3.20 | 3.20 | |

Apparent porosity,% | ≤ 14.0 | 12.5 | ≤ 17.0 | 16.5 | |

Cold Crushing Strength(C.C.S),Mpa | ≥ 100.0 | 103.8 | ≥ 60.0 | 75.0 | |

Refractories Under Load,°C | > 1700 | > 1700 | > 1700 | > 1700 | |

Thermal Shock Resistance[TSR] 1100 °C × Water | 5 | 5 | 8 | 8 | |

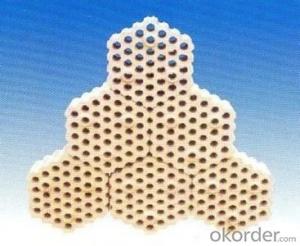

Chemical Composition,% | Al2O3 | ≥ 80.0 | 84.5 | ≥ 80.0 | 82.3 |

Cr2O3 | ≥ 12.0 | 13.7 | ≥ 12.0 | 13.4 | |

Application | Used in coke slurry and coal slurry boilers | ||||

Quick Details

| Place of Origin: | China (Mainland) | Shape: | Brick | Material: | Chrome |

| Al2O3 Content (%): | 80% min | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | 13% min |

| Model Number: | RF-LG-8013 | Brand Name: | Luoyang refractory |

Packaging & Delivery

| Packaging Detail: | wooden pallet or as customer's request |

| Delivery Detail: | Within 30-40 days |

Specifications

1.High-middle grade refractory materials

2.Manufacturer for refractories

3.Stable quality

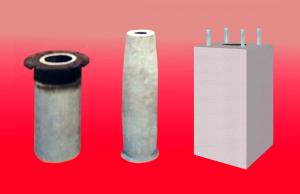

- Q: What is the blast furnace ceramic cup called by the refractory factory?

- The peak of new materials in various coal, metallurgy, mines, ports, electricity, building materials and military industry, a lot of workpiece and affect production equipment due to wear, wear resistant materials although rarely cause disasters metal workpiece disaster, but the resulting economic loss is immeasurable.

- Q: What's the jade stove for?

- Is it a furnace made of corundum or a furnace for smelting corundum?Corundum brick stove is commonly used as a refractory material sintering furnace, can be fired refractoriness in refractories, below 1700 degrees such as brick, corundum brick, brick, alumina hollow ball and so on

- Q: What equipment is used for producing diamond blanks? How much is the investment?

- You'll have to invest about about one million if you want an electric furnace. A power distribution room is easiest to approach one hundred thousand. Electric furnaces, power distribution cabinets and transformers must be around one hundred and ten thousand.

- Q: Which is good, glazed brick and whole cast glazed brick?

- The main advantages of all glazed glazed tiles are that they can be very rich and beautiful in texture and pattern, and they are suitable for family decoration, and can choose patterns according to their own family decoration style. Compared to the glazed tile, it has better pollutant discharge performance, and many pollutants are difficult to penetrate into it.

- Q: Wave tile and throwing glaze, tile which good?

- The main advantages of all glazed glazed tiles are that they can be very rich and beautiful in texture and pattern, and they are suitable for family decoration, and can choose patterns according to their own family decoration style. Compared to the glazed tile, it has better pollutant discharge performance, and many pollutants are difficult to penetrate into it.

- Q: Can the PE sintering plate dust collector be suitable for dust removal in the coking plant?

- The sinter plate dust collector is also called plastic plate dust collector. The utility model has the advantages that the utility model can adapt to various complicated working conditions, the dust removal rate is 99.99%, the utility model has the advantages of long service life, stable operation, high temperature resistance, and the utility model is a leading dedusting equipment in china.

- Q: High temperature refractory material?

- Acid refractory with silicon oxide (SiO2) as the main ingredient, commonly used are silica brick and clay brick is siliceous. Products containing more than 93% SiO2, the use of raw materials with silica, silica and other waste brick. Acid slag erosion ability is strong, but vulnerable to the erosion of basic slag, its softening temperature is very high that is close to the refractory, the volume does not shrink after repeated burning, or even a slight swelling, but the thermal shock stability. Silica is mainly used for thermal equipment of coke oven, glass furnace, furnace and other acidic silica brick, according to the physicochemical indexes and SiO2 content can be divided into several levels, mainly brick for glass furnaces and used for coke oven two kinds of brick clay brick. With refractory clay or bauxite clinker as main raw material, containing 30% to 46% of alumina, refractory degrees 1580 to 1770 DEG C, weak acid refractory material, heat shock resistance, resistance to acid slag, wide application Pan, clay brick with refractory clay as main raw material is called ordinary clay brick, made with bauxite clinker as main raw material, the porosity in the clay brick below 17% is called low porosity clay brick. Two kinds of clay brick and according to the physicochemical indexes which were divided into several grades, the price difference between ordinary clay brick and low porosity clay brick greatly.

- Q: How do corundum bricks bind?

- Each refractory brick is provided with corresponding refractory mud, and corundum bricks are bonded with corundum mud.

- Q: Ask for help about the phase of refractory material

- Major crystalline phase. The main crystalline phase is a crystalline phase that constitutes the principal part of the material structure and has a high melting point and a dominant role in the properties of the material. The properties, quantities, distribution and bonding state of the main crystalline phases of refractory determine the properties of the products directly. A lot of refractory products, such as mullite brick, corundum brick, magnesia brick, magnesia spinel brick, silicon carbide refractory products, etc., are the main phase named.

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- The T3 in T3 refractory bricks refers to the model indicating that the refractory brick model is T-3, and that the corresponding T-3 model is 230*114*65 (mm)

Send your message to us

Corundum Alumina Chrome Brick CNBM Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords