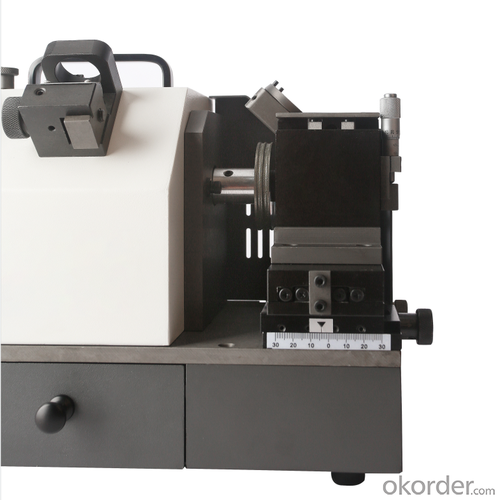

Corner Radius End Mill Re-sharpener X6RA for Grinding Bull Nose Milling Cutter

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

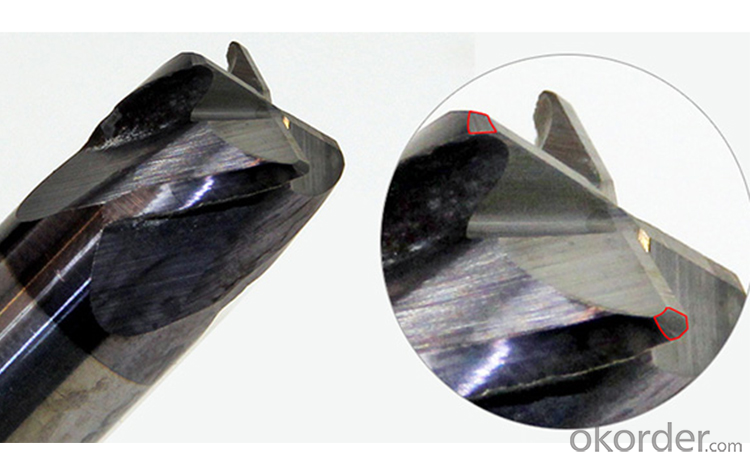

1. It is specialized in re-sharpening end mill and corner radius end mill, it can grind 2-flute, 3-flute and 4-flute, Optional fixture group can grind 5-flute end mill cutter (bigger than Φ12mm can grind 6 -flute end mill). Also use the tungsten bar to cut cutting edge directly.

2. It can grind the radius of corner radius end mill as R0.3, R0.5, R0.8 and R1. If there is any other radius, we can make the customized grinding wheel.

3. Grinding is accurate and rapid, easy operation, with no skill requirement to grind easily.

4. With Taiwan diamond grinding wheel, it can be equipped directly with an accurate angle and long service life.

5. The electrically controlled and powerful DC motor, stable frequency, strong horsepower and long service life.

Standard with SDC grinding wheel for the Carbide material, Optional CBN grinding wheel for the HSS material.

Standard equipments:

Collet chuck: 2 sets

Standard SDC grinding wheel: 2 pcs (for carbide)

ER20 collet: 6 pcs (ф4, ф6, ф8, ф10, ф12,ф14) ; ER25:Φ16, Φ18, Φ20

Hexagon wrench: 1 set

Technical Parameters

Model: | X6RA |

Diameter: | Φ4-Φ20mm |

Power: | 220V/250W |

Speed: | 4400rpm |

Point angle: | 0°-5° |

Dimension: | 42*25*30cm |

Weight: | 23KG |

Standard Equipment: | Face grinding wheel: SDC (for carbide)×1 |

R grinding wheel: SDC (for carbide)×1 | |

Nine collets: ER20:Φ4,Φ6,Φ8,Φ10, Φ12,Φ14; ER25:Φ16, Φ18, Φ20 | |

One collet chucks | |

optional Equipment: | Face grinding wheel: CBN (for HSS) |

R grinding wheel: SDC (for carbide)×1 |

Remarks:

Applicable cutting tool

Package

Q&A

Q1. Where is your factory located?

A : Our factory is located in Taizhou City, Zhejiang Province, China.

Q2. What is your MOQ of your machine?

A: Normally our MOQ is 1 set.

Q3. Do you test all your machine before delivery?

A: Yes, we have 100% test before delivery.

Q4: What is the payment term?

A: T/T 100% payment. We'll show you the photos of the products and packages before shipping.

Q5: What is the normal lead time?

A: If in stock, it usually takes10-15 days. 20-30 days if not in stock, depending on quantity.

Q6: Guarantee Period?

A: 1 year only for motor.

Send your message to us

Corner Radius End Mill Re-sharpener X6RA for Grinding Bull Nose Milling Cutter

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches