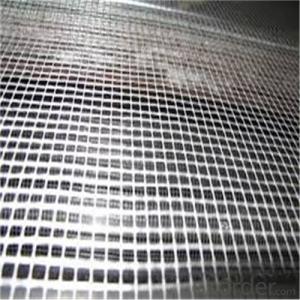

Fiberglass Mesh for Concrete - Core Mat 2:High Quality & Competitive Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CORE MAT

PRODUCT DESCRIPTION

CORE MAT is a stratified reinforcing glass fiber fabric composed by 5 layers. 2 exterior layers of random mat, 1 layer of woven roving and 2 layers of synthetic fibers. The main application is for RTM and RTM Light parts where mechanical performance is a must.

CONSTRUCTION

CORE MAT has been manufactured by stitch bonding technology. The 5 layers are arranged as follows:

Layer 1: Random glass fiber mat

Layer 2: Synthetic Web

Layer 3: Woven roving

Layer 4: Synthetic Web

Layer 5: Random glass fiber mat

The layers 2 and 4 are made by a synthetic material (polypropylene)and the main purpose of these layers is to allow the resin flow and provide compressibility to the reinforcement.

STYLES

The standard materials are the ones in the following list, but other designs are also available according to customer needs

Specification Glass fiber G/M2 Total dry weight G/M2

250BWR500B250 1000 1250

350BWR500B350 1200 1450

450BWR500B450 1400 1650

250BWR800B250 1300 1550

350BWR800B350 1500 1750

450BWR800B450 1700 1950

How to understand CORE MAT description:

Example:

250BWR500B250

- Q: Hydraulic oil filter, glass fiber or imported paper is good?

- The HEPA screen made of glass fiber is generally accepted to achieve high efficiency. Because of the high requirement of glass fiber in making technology, the quality of products is low.

- Q: The difference between the gridding cloth and iron gauze What materials should be used for thermal insulation of external and internal walls?

- The current technical standards (JG) for thermal insulation gridding cloth of external walls: alkali resistant fiberglass mesh warp weft tensile breaking strength: 750 n / 50 mm, alkali tensile breaking strength retention rate: 50%, weight/㎡: ≥130 grams JG alkali resistant fiberglass mesh warp weft tensile breaking strength: 1250 n / 50 mm, alkali tensile breaking strength retention rate: 90%, weight/㎡: 160 grams, or breaking strength and alkali resistance strength retention: as all know, the breaking strength and alkali resistance strength retention, important performance: breaking strength, glass fiber gridding cloth and glass fiber count or weight Currently the glass fiber gridding cloth for thermal insulation of external walls is about 130 grams/㎡ with relatively lower quality and 160 grams/㎡ with standard quality. With platinum glass fiber as base material, gridding cloth is coated with emulsion with good alkali resistance and high tensile resistance in the bidirection of warp and weft, thus featured by smoothness and reducing the mortar amount.

- Q: Is glass fiber harmful to human body?

- Skin damage: glass fiber workers have contact dermatitis, but some workers can gradually tolerance, known as "hardening" phenomenon. The extent of skin damage depends on fiber diameter and surface roughness. It is now accepted that fiber diameter exceeds 5 mu m, which has a significant stimulating effect. A small number of people exposed to glass fiber and rock wool have skin allergies, but so far they have not been proved to be allergens.

- Q: The difference between alkali resistant mesh cloth, emulsion and urine glue

- Relatively better quality products than latex products produced urine glue surface is relatively soft but not broken some customers customized urine gum products according to different uses, our factory can also be customized according to customer requirements of the corresponding products in general

- Q: Are epoxy resins and glass fibers the same kind of thing?

- Glass fiber is a kind of inorganic non-metallic material with excellent performance. It has many advantages, such as good insulation, good heat resistance, good corrosion resistance and high mechanical strength, but its disadvantages are brittleness and poor wear resistance. It is a glass ball or waste glass as raw materials by high temperature melting, wire drawing, winding and weaving process for production, the filament diameter of several microns to twenty micron, the equivalent of a hair 1/20-1/5, each bundle of fibers by hundreds or even thousands of root root filaments.

- Q: What is the standard of external wall thermal insulation mesh?

- External wall thermal insulation mesh 1, interior wall thermal insulation mesh specifications: Mesh size: 5x5mm, 4x4mm gram weight: 80g165g / m2 Width: 1000mm2000mm length: 50m300m 2, external wall thermal insulation mesh specifications: Mesh size: 5x5mm, 4x4mm gram weight: 80g160g / m2 Width: 1000mm2000mm length: 50m, 100m or 200m Color: White (standard), blue, green or other colors Packing: According to customer requirements 3, GRC enhanced mesh product specifications: Mesh size: 8x8mm, 10x10mm, 12x12mm gram weight: About 125g / m2 width: 600mm, 900mm, 1000mm length: 50m or 100m Color: White (standard), yellow, green or other colors Packing: According to customer requirements 4, glass?fiber tape specifications: Specification: 8x8mm, 9x9mm gram weight: 55g85g / m2 Width: 25mm - 1000mm length: 10m150m Color: It is usually white mesh is the indispensable material in the vast majority of insulation materials, including rivet and various mortar. The interior wall mesh is made of glass fiber as the main raw material, but also through the multi-channel processes. The interior wall mesh is ideal material for grc wallboard.

- Q: Is fiberglass mesh also called as stone? Why?

- No, it isn't. Fiberglass mesh is just the auxiliary material to reinforce fragile stone like marble and improve adhesive strength.

- Q: Exterior wall insulation, alkali resistant mesh cloth in the door window flip bag approach?

- The doors and windows should be done to strengthen bladder surrounding layer, strengthening layer grid cloth on the inside of the door window frame. If the skin and the base wall surface is larger than the 50mm mesh and the base wall paste. If less than 50mm, you need to do the package disposal. Great wall laying mesh should block entry window outside of cement.

- Q: What is the function of interior design mesh?

- Its raw material is medium alkaline or non-alkaline glass fiber yarn. Modern buildings are made from concrete or bricks. The features like crack resistance can be restored. This is lightweight wall.

- Q: If external insulation material is insulation putty, is it necessary to wrap external corners of mesh?

- Before being paving, mesh shoule be scraped a leveling blamket with cracking resistant mortar on insulation layer. Then paste mesh, slightly press it with trowel, and scrape another cracking resistant mortar to make sure that mesh is outside of the cracking resistant mortar so that it is crack-resistant.

Send your message to us

Fiberglass Mesh for Concrete - Core Mat 2:High Quality & Competitive Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords