Copper Mylar Shielding Foil for Cable Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Copper Mylar foil Shielding Foil for Coaxial Cable communication cable

1.Structure of Copper Mylar foil Shielding Foil Description:

Electrical cable is used to transfer electricity, information and the realization of electromagnetic energy transformation. The electrical cable in a broad term mainly indicates to cable and in a narrow term indicate insulation material. Its definition is the aggregation of different parts below: one or more insulation cores, the wrapping layers of the cores, the general protective layers and the outer protective layers. Cables also include additive conductor without insulator.

2.Main Features of the Copper Mylar foil Shielding Foil:

Copper Mylar foil Shielding Foil is applicable to the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

1.Thickness: min 6.5mic; width: 300-1000mm.

2. According to GB/T 3198-2010.

3.Usages: cable shield, candy wrap

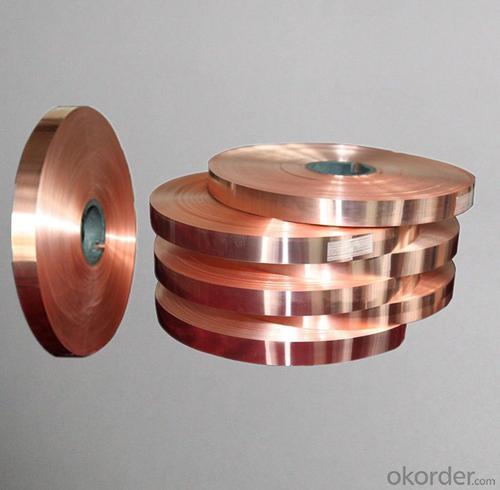

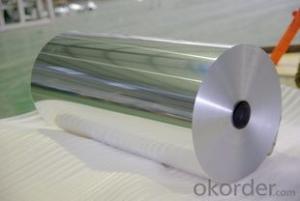

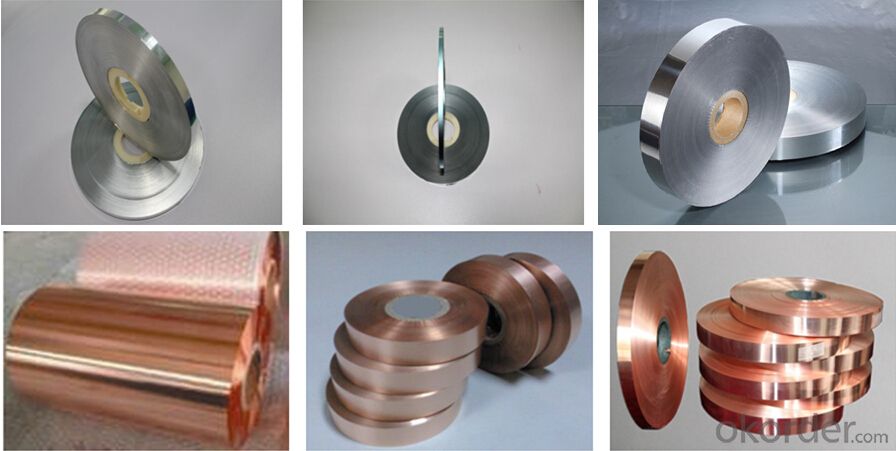

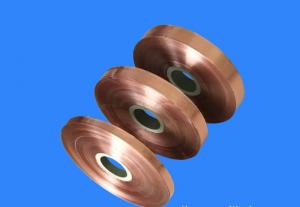

3. Copper Mylar foil Shielding Foil Images

4. Copper Mylar foil Shielding Foil Specification

AL-PET laminated foil

Description: Apply for overall or individual twisted pair shield for electronic cable and local network cables, protect from external electromagnetic interference. Features option of LUBRITAPE apply to decrease 50% friction of aluminum surface.

Construction: Aluminum foil, Polyester film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

FP007012 | 22±3 | 7 | 3 | 12 | 38.8±5% |

FP010012 | 25±3 | 10 | 3 | 12 | 46.9±5% |

FP020020 | 43±3 | 20 | 3 | 20 | 83.8±5% |

FP025012 | 40±3 | 25 | 3 | 12 | 87.6±5% |

Special specifications are also available, according to customer’s order. | |||||

AL-PET-AL laminated foil

Description: resilient shielding in cable assembling and provide the enhanced shielding required in harsh environments.

Construction: Aluminum foil +Polyester film+ Aluminum foil

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | WEIGHT |

DFP007015 | 35±3 | 7 | 3 | 15 | 3 | 7 | 65±5% |

DFP009020 | 39±4 | 9 | 3 | 15 | 3 | 9 | 76±5% |

DFP015025 | 61±5 | 15 | 3 | 25 | 3 | 15 | 115±5% |

DFP025025 | 80±5 | 25 | 3 | 25 | 3 | 25 | 175±5% |

Special specifications are also available, according to customer’s order. | |||||||

Bonded AL-PET laminated foil

Description: A laminated aluminum-polyester-aluminum tape is fully bonded to the foam dielectric to provide 100% coverage, longitudinally applied over the polyethylene core and the tape minimizes signal leakage.

Construction: Aluminum foil + Polyester film + Aluminum foil + EMAA film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | GLUE | EMAA | WEIGHT |

DFPH009012 | 65±5 | 9 | 3 | 12 | 3 | 9 | 3 | 25 | 98±5% |

DFPH009020 | 72±5 | 9 | 3 | 20 | 3 | 9 | 3 | 25 | 108±5% |

DFPH009025 | 75±5 | 9 | 3 | 25 | 3 | 9 | 3 | 25 | 114±5% |

DFPH010025 | 84±5 | 10 | 3 | 25 | 3 | 10 | 3 | 25 | 126±5% |

Special specifications are also available, according to customer’s order. | |||||||||

Copper polyester foil

Description: Copper foil, copper lamination foil typically use as shielding for low/medium voltage cable and radio frequency coaxial cable. The rolled annealing copper foil is flexible to wrap cable core, also it has the excellent physical properties, Polyester film provides electrical insulation and high mechanical properties.

Construction: Copper foil + Polyester film

CODE | TOTAL THICKNESS | CU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

CP018012 | 33±3 | 18 | 3 | 12 | 175±10% |

CP007020 | 46±3 | 18 | 3 | 25 | 195±10% |

CP015012 | 30±3 | 15 | 3 | 12 | 160±10% |

Special specifications are also available, according to customer’s order. | |||||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this foil?

Aluminum Mylar foil Shielding Foil is used for cable shield, candy wrap for the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: The self sealing bag is made of pure aluminium foil or kraft paper. How about the tightness?

- Of course, the tightness of the pure aluminum foil bag is good!Custom aluminum foil bag of words, I suggest looking for pure aluminum foil bag manufacturers customized experience, because it can reduce the cost and time for many of you, can give you a lot of packaging design and customized recommendations.

- Q: How do you handle the cursor distance of the foil composite film?

- What is the structure of your structure?Composite aluminum foil, please use special adhesive for aluminum foil, if you can afford the price, you can consider using aluminum foil cooking gum, so that the peel strength will be better.

- Q: Aluminum foil surface, SBS roll multilayer superposition, waterproof effect is good?

- Single sided aluminum foil is a mylar foil, also known as plastic tape. The soft rolling aluminum foil and polyester film as raw material, the dry intaglio compound, to foil Mylar film aging after cutting into rolling. One side is the side of aluminum foil Mylar, with side side insulation, conductive function.

- Q: Battery why aluminum foil as anode, copper foil as negative electrode?

- In addition to stability, it is necessary to consider the conductivity of the material, whether it can be machined thin, as well as mechanical strength, cost and other factors. Finally chose Cu and Al.

- Q: What is a composite aluminum foil molded poly vinyl foam board, and what is a composite aluminum foil extrusion poly vinyl vinyl insulation board, the two how to distinguish?Please try to be more specific

- A kind of composite heat preservation board with aluminum foil is used in air conditioning and air duct insulation1, the insulation material molded type insulating materials used is moulded polystyrene foam board, also known as EPS, commonly used household appliances packaging materials is the white foam foam board; the extruded insulation material is extruded polystyrene foam board, which is XPS.

- Q: What are the characteristics of aluminium foil waterproof coiled material?

- Aluminum foil paper is soft and easy to change, like paper, and it doesn't bounce after deformation. It can be assured that shading will not fall, light, pollution free and cheap. For high grade cigarettes, sweets and other food moistureproof and decorative packaging.

- Q: What is the difference between aluminum foil and aluminum foil?

- For the barbecue, is the foil, but used to call it the foil (when people have never seen a foreign thing, and that is very much like a tin foil, foil)

- Q: Processing method for waste aluminium foil composite film

- Wooden artificial board, wooden line and assembled wooden floor etc.

- Q: What is the aluminum foil?What is it?

- With metal foil Mylar foil backing, and adhesive polyester tape (PET PP) attached to the thin, 7 m and 9 m aluminum foil, in recent years with the change trend of electronic industry products small thin, the thickness of 4UM foil has gradually increased, due to the application of industry and different end use.

- Q: In case a bright paper is aluminum foil or foil with what method can distinguish and what contain aluminum foil

- Because tin costs a lot, no one actually does itThe difference between foil foil or method can be used for burning, two different melting point, the low melting point of tin.

Send your message to us

Copper Mylar Shielding Foil for Cable Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords