Construction Use LVL

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1X20' FCL m³

- Supply Capability:

- 3000 CBM per month m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

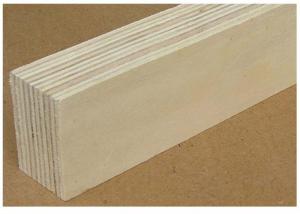

Specifications for Construction Use LVL

| Size | Wide(Max.1250mm*length(Max.6000mm) |

| Thickness | Max.50mm |

| Glue | WBP/melamine/MR |

| Material | poplar wood, Eucalyptus,pine |

| Usage | For construction,used for permanent structural applications including beams, lintels,truss chords and fromwork |

| Grade | A Grade |

| Package | Standard export packing,Pallet matal strip |

The usage for the Constrction Use LVL

Laminated Veneer Lumber is a high-strength engineered wood product made from veneers bonded together under heat

and pressure. It is used for permanent structural applications including beams and rafters. It is also widly used in the

furniture making, wooden packing boxes like packing machine or glass, and bed flame etc.The ability to cut different

shapes from the LVL sheets allows for structural innovation using angular and curved shapes.

Applications and Advandages of the Construction Use LVL

Laminated veneer lumber (LVL) is an engineered wood product that uses multiple layersof thin wood assembled with adhesives.

It offers several advantages over typical milled lumber.it is stronger, straighter, and more uniform. It is much less likely than

conventional lumber to warp twist, bow, or shrink due to its composite nature. Made in a factory under controlled specifications,

LVL products allow users to reduce the onsite labor.

Instruction for the Construction Use LVL

.It is similar in appearance to plywood without crossbands and is typically rated by the manufacturer for elasticmodulus and

allowable bending stress. Common elastic moduli are 1.8, 1.9, and 2.0 million psi, and common allowable bending stress values

are 2800 and 3000 psi.

Packing and delivery of the Construction Use LVL

Packing details: standard export packing

Delivery Port: China main port

The following pictures for reference:

- Q: How to handle the business license and tax registration certificate for wood products processing plant?

- To carry the company's articles of association, shareholders' meeting resolution, real estate certificate or housing lease contract, capital verification report, shareholder ID card and then go to the Trade and Industry Bureau for business license. Second, carry a copy of the business license to the local Quality Supervision Bureau, for the organization code certificate. Third, carry a business license and organization code certificate to the local IRS, for tax registration certificate.

- Q: How to use wood products paint

- 2. White paint, with a base of gray scraping the bottom, the same as above. 3. paint, to use a special colored soil (building materials market have to sell) plug holes, holes, insect eyes nail eyes and other places, and then ibid If it is a traditional paint such as alkyd paint, etc., to the upstairs said the same. Diluted with water that day, spray can be.

- Q: How much is the woodworking painting

- Before the paint is past the paint before the first paint stripping with paint, the unit price of 50 yuan / square red paint: labor costs 30-35 yuan / square, auxiliary materials 5 yuan / square, paint 25 yuan / square, 60-65 yuan / square (cost price)

- Q: Whether it belongs to wood products

- Wooden box: Clothing box food box health care products packaging box moon cake box tea box Cordyceps tea box bird nest box ginseng box wine box box gold and silver coin box commemorative coin box coin box perfume box glasses box cosmetics box collection box luxury box toolbox

- Q: Laser marking machine engraved wood products will be black

- If it is pulse, then by increasing the Q frequency, increase the pulse width and other measures can be achieved.

- Q: Who knows the art of wood on the brush is what oil?

- First, simply answer as follows: The first layer is tung oil, not paint, the role of tung oil should be anti-corrosion, the outside layer is a varnish, varnish role is smooth and bright.

- Q: Will the small wood products of the dipping (paint) should be how the production process?

- Followed by the primer is closed. After the primer can be dry after the paint.

- Q: Water content is too high or too low, will cause the quality of wood in the home improvement

- Because solid wood materials are textured, so the temperature, humidity changes when the larger, there will be cracking, warping with the deformation of the scene.

- Q: What are the wood products?

- Only relatively environmentally friendly products exist, that is, the application of time or the number of applications and the ratio of the greater the better.

- Q: To which country the wood products must be fumigated

- Exporting wood packaging needs to fumigation in the country: The United States, Canada, Brazil, the Philippines, South Africa, New Zealand, South Korea, Japan, Mexico, Turkey, the European Union, Chile, Australia, Vietnam, Taiwan. In international trade, countries to protect their own resources, some imported goods to implement a mandatory quarantine system. Wood packaging fumigation is a precautionary measure taken to prevent harmful pests from harming the forest resources of the importing country. Therefore, the export of goods containing wood packaging, it must be shipped before the wood packaging for pesticide treatment, fumigation is a way to deal with pesticides.

Send your message to us

Construction Use LVL

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1X20' FCL m³

- Supply Capability:

- 3000 CBM per month m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords