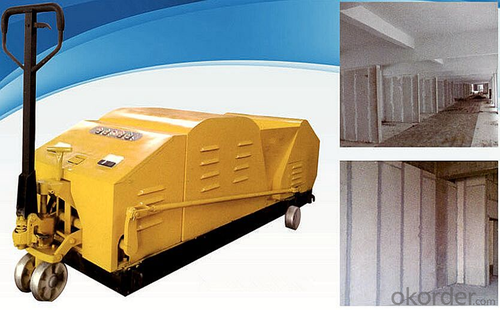

Concrete hollow wallpanel machine HQJ150-600

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

· Condition: New

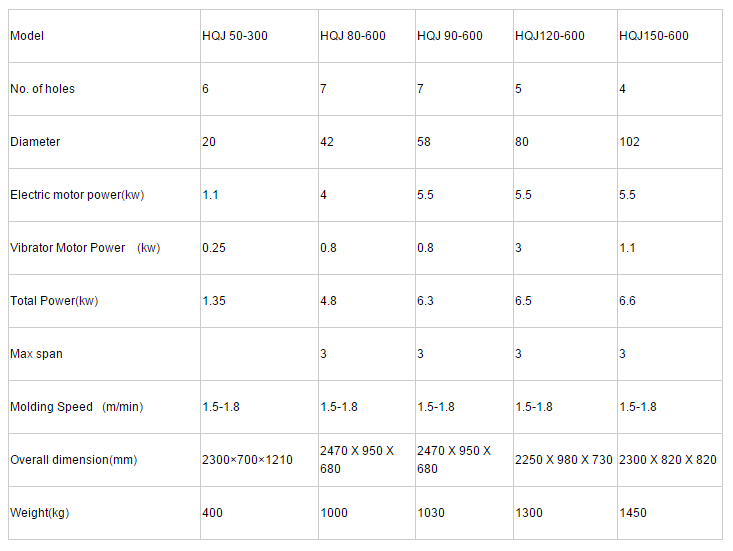

· Application: prefab building

· Automatic Grade: Automatic

· Production Capacity: 60-70m/h

· Place of Origin: Shandong, China (Mainland)

· Brand Name: LING FENG

· Model Number: SL80*600

· Voltage: 360v

· Power(W): 4.5-8.0kw

· Dimension(L*W*H): 2.5*1.0*1.0m

· Weight: 2.0T

· Features: high efficiency

· Certification: ISO9001/CE

· Warranty: 12 months

· After-sales Service Provided: Engineers available to service machinery overseas

· Main frame: 2.0*1.4m

· Color steel thickness: 0.3-0.8 mm

· Insulation: first class

· Shaft axis: diameter 80

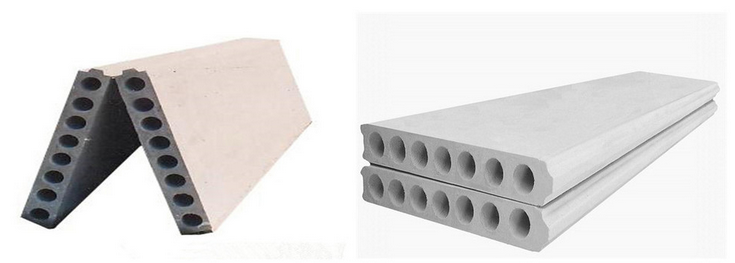

· Brick Raw Material: Cement, sand, stone.

· Strength: water proof, fireproof, sound proof

· Vibrator type: ZW type 3.0kw

· Motor model: YEZ132S-4-B5

· Color: yellow or custom

· OEM: available

Products

Quality

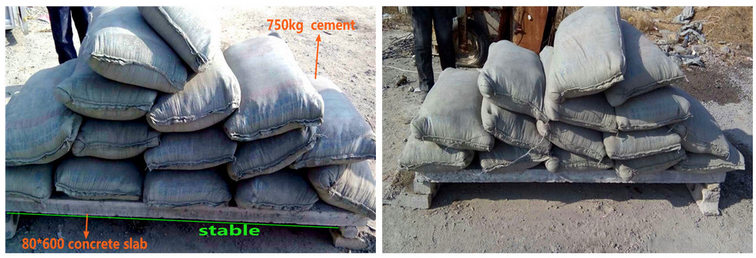

Packaging & Delivery

Packaging Details: Wooden case and wood flour into the bottom of the box.

Delivery Detail: Within 15 days

Major Parts and advantage of lightweight wall panel machine

Features:

I. Anti-corrosion and wear-resistant.

The machine frame is made of manganese steel whose quality is better than normal steel. The interior side of the mould is made of stainless steel (its thickness can be 2.2mm) which can stand repeated use and corrosive materials. It can be used for over 10 years. Besides, panels made by this kind of machine have better quality than other kinds. The panel will not be deformed. Its surface is smoother than others.

II. High capacity

Normal hollow core wall panel machine can make only ten panels in one mould, but this machine can make 14 panels at one time.

III. Energy-saving

The machine uses storage battery as power which can save a lot of electricity and is safe to use. Besides, if there is something wrong with the machine in the production line, it will not influence the use of other machines.

IV. Lower the cost of production

We use stainless steel for the mould instead of traditional steel. Steel mould machines need brushing de-molding agent or the panels can't be taken out. Stainless steel machines need a little de-molding agent, this can save both labor and material cost for manufacturers.

V. Hydraulic mould closing and opening

The mould is opened and closed by hydraulic. Its moving is very smooth and stable. All the four sides of the mould can be opened together, so it is very easy to use and it can save labor and cost.

VI. Unique design

We have special design not only for the single machine, but also for the whole production line. Our mixer can be customized for the customer according to their requirement. We also have special equipment to get rid of the dust so that the production is very clean.

Our Services

Interests in the good faith, interests in quality, interests in the service

Customer visits and technical guidance provides 24-hour service and lifetime maintenance services, supply of spare parts. Site church consumer operation, teach operating essentials, equipment maintenance and production experience, considerations.

Our factory can produce all kinds of equipment and prefabricated factory accessories according to customer demand.

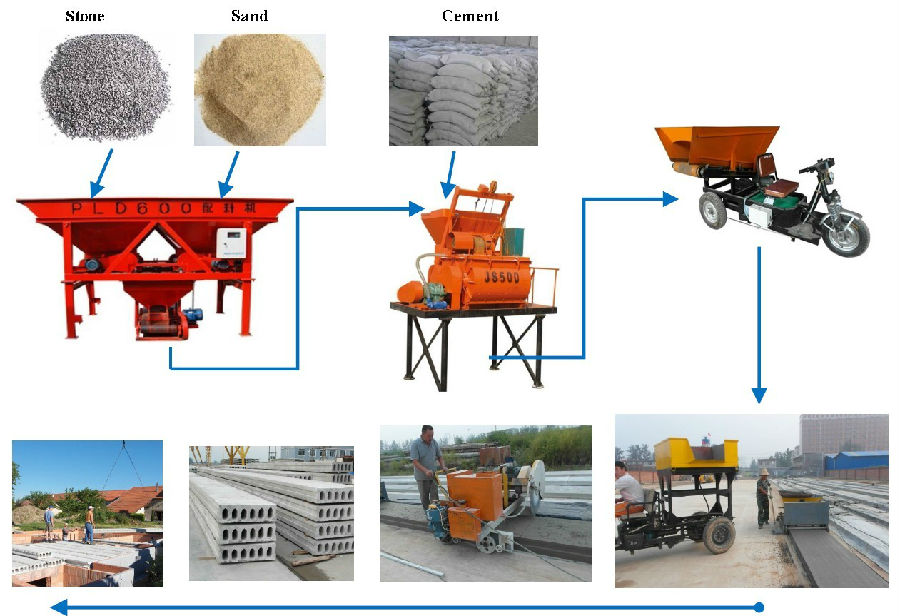

Flow chart:

Other available machines:

- Q: Where are the second-hand machinery and equipment acquisition?

- A wide variety of mechanical equipment, mechanical equipment, some of its components and even its own can be carried out in different forms of mechanical movement. The mechanical equipment is composed of driving device, speed change device, transmission device, working device, brake device, protection device, lubricating system and cooling system.

- Q: Any used heavy earth moving machinery for sale/auction in maryland(MD)?

- The website below may provide some tips on locating heavy machinery for sale in MD.

- Q: Any one no og some good pec exercises i can do without machinery or equpitment? i no of the obv. push up but i was thinking more of like a seated work out thx

- does a medicen ball count as machinery? becuase you can do really good accross body workouts with them :)

- Q: What's the level of the construction machinery in China?

- First, the team is definitely not, but it takes up most of the second team.

- Q: Hello! We are a firm located in Nasik, India. A company from Texas, USA wants to buy 4 of our used machines and transport them to the USA. My questions are:What is the procedure to be followed for this purchase? What all documents or agreements need to be signed? Do we need Law signatures on the purchase agreement both from India and USA or just any one?Your replies are appreciate.

- 1. The question has an Exchange Control angle, apart from other things. The shipping documents have to be rounted through a bank in India(authorised dealer in foreign exchange). Remittance from USA to India will also have to be routed through a bank(authorised dealer in foreign exchange). 2. A bank, being an Authorised Dealer in Foreign Exchange (SBI, BOI, BOB, ICICI Bank, HDFC Bank, etc., etc.) will give necessary guidance in the matter, including the documentation part. 3. Reserve Bank of India has delegated many powers under Foreign Exchange Management Act to Authorised Dealers in Foreign Exchang (banks). 4. Please visit a bank and enquire. .

- Q: Is the construction machinery good? How about employment?

- The words are generally go to the factory when the technical director, prior to when the apprentice

- Q: I'm pretty disturbed about this whole deal. So she doesn't have certain female components.. does that make her a man? Is that why she ran so much faster than everyone else in Berlin? Are men really that much faster than women? Do you think she knew?

- Face it, estrogen's only redeeming value is to make a woman look supple and moist and give her reproductive capabilities. It's a real drag otherwise. So, she was born a hermaphrodite, so what, the more power to her. More women should be so lucky. Too many people in the world anyway especially in Africa where she comes from. Obviously, she has a lot more testosterone floating through her veins than estrogen. Just because she doesn't have octo-mom capabilities, everyone is on her case. She just happens to have all the ingredients to be what she is and that is a no-hands down world class champion. I suppose they could try to clone her LOL!!!!

- Q: why was machinery the most powerful weapon in the war of capital against the working class?

- They lessened the need for skilled laborers

- Q: What is the relationship between XCMG, construction machinery, Limited by Share Ltd and Xuzhou Construction Machellonery Group Inc?

- The name of XCMG construction machinery Limited by Share Ltd, you can see the front of the two words is a stake in Xugong Group and the middle, the company is a listed company under the Xugong Group, referred to as Xugong Xugong Group, because not all listed, so the company is a company which XCMG group as a whole.

- Q: For a project in college I need to know what machinery (JCB etc) is used for deep excavations. Does anyone know? I can research their functions myself but I can't find any types of machinery used online. Help?Thanks in advance

- Sandvic D C120 Hydraulic drilling unit is used for drilling, CATTERPILLER make Excavator 330 DL and L T Komatsu PC 300 Volvo excavator etc are bing used for Deep Excavation. Please contact local office of the above said companies(L T, CAT, Hyuyidai, Vova) and enquire model No for the your applications.

Send your message to us

Concrete hollow wallpanel machine HQJ150-600

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords