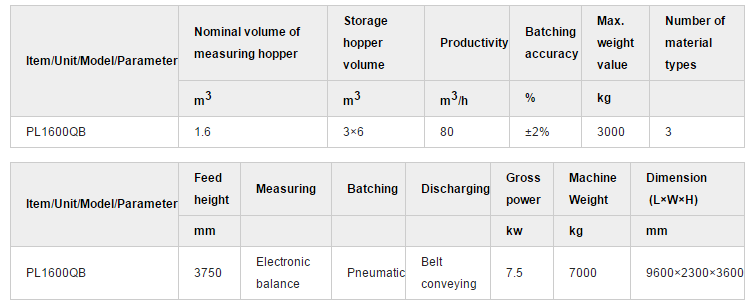

Concrete Batching Machine PL1600QB / CE & ISO Certificate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The Technology Center of Yuanyou Heavy Industry is a certified Enterprise Technology Center of Shandong Province; it has a mass of senior R&D engineers, good R&D environment and R&D mechanism which inspirit strong R&D and innovation ability. The center mainly focuses on the technical research, the application of the new technologies and materials, and the development of new products in the fields of construction machinery, building machinery, road machinery, and dry mixed mortar equipment, etc.

The Technology Center is the product and R&D department of Shandong Yuanyou Heavy Industry Science & Technology Co., Ltd., which mainly undertakes the technology and product R&D and technology management. There are five R&D departments, respectively mixing machinery R&D department, dry mortar equipment R&D department, construction machinery R&D department, automation R&D department, and new material R&D department. Every year, there is technology innovation and technical transformation project selected as major project of Weifang city or Shandong province. The recently developed energy-saving and environment friendly air-conveying concrete mixing plant is selected as one of the major technical innovation projects of Shandong province, and it gains the certificate of New Product and New Technology of Shandong Province. The project of “Technical Transformation Project of Energy-Saving and Environment Friendly Air-Conveying Concrete Mixing Plants” with annual output of 200 is approved to be the Top 10 Major Energy-Saving Engineering Project in China and the New Central Government Budgeted Investment Plan Project by National Development and Reform Committee (NDRC). The success of the product lays a solid foundation for the product upgrade and structure optimization, and plays an active role in expanding market and promoting the development of the enterprise. The center always insists on combining the production with research, and successively sets up relationships with colleges and research institutes.

The product is widely used in key projects like various highways, railroads, high-speed railways, airports, ports, bridges, and hydropower stations, as well as commercial concrete mixing station, real estate, and municipal construction. With constantly increasing investment in technological innovation, the company has achieved great achievements and been recognized as “Provincial Enterprise Technology Center” in 2008. The company has 4 research department respectively specializing in mixing, transportation, conveying, and automation.

- Q: What kind of sand do you need for a concrete plant? I don't know where to start!

- Give you a website to see. Specializing in concrete mixing stations. Hope that useful.

- Q: Cement warehouse introduction, storage reserves?

- Cement silo in concrete mixing plant is mainly used for the storage of bulk cement, there are usually used 80 t, 100 t, 120 t, 150 t, etc., this is according to the size of the concrete mixing station or the user's production decision.

- Q: What is the concept of on-site concrete mixer station

- It's not a simple blender. It's not a simple blender. But an intensive production scale small and use the site concrete, according to the need to establish a set of automatic production line, divided into according to production output per hour 35 square (45), 50 square (60), 75 (90), 90 (120), the standard station with laboratory; To establish the corresponding scale of the stations according to the construction needs; This kind of mixing station can not only guarantee the quality of concrete, but not the time factor, which guarantees that 24 hours can produce the concrete needed for the site. He needs to have about 30, 000 or so in demand, and the site is suitable. This has low cost, convenient site management and mutual benefit!

- Q: What are the supporting facilities for the concrete mixing stations?

- Concrete mixing equipment, concrete transport equipment, laboratory equipment, forklift, overpound equipment, ground pump, car pump etc.

- Q: How much water does a concrete mixer use every day?

- It is also a waste of water to flush the transports. Suppose you flush a vehicle with 1-2t water, rinse it 2-3 times a day, and use 20 cars a day for a medium size of a blender, 40 to 120 t a day. From this perspective, the reuse of washing water is very conducive to environmental protection and water conservation. The rational recycling of water in the mixing stations is also gradually being promoted. Our new hydraulic patent product concrete wastewater and sewage circulation recycling used by many domestic manufacturers, most of new mixing plant began to use the recycling equipment. The wastewater recovery system has made some efforts for the environmental cause of China.

- Q: What are the facilities of the concrete mixing station

- It can be divided into five large parts of the mixing host, material weighing system, material conveying system, material storage system and control system

- Q: What are the advantages of HZS series of concrete mixing stations

- HZS75 concrete batching plant investment amount, less occupied area is small, the use of equipment, maintenance easy, can be equipped with high performance of independent control room, make the equipment operation convenient and safe, and in the batching machine also can produce high quality under the condition of accurate measurement of concrete. This type of mixing station under our positive study also used the green environmental protection design, the construction of a possible pollution under control, rather than the old way of construction and transportation pollution, nature is winning.

- Q: Concrete mixstations belong to no special equipment

- Special equipment is referred for life safety, greater danger of boilers, pressure vessels (including gas cylinders, hereinafter the same), pressure pipes, elevators, lifting machinery, passenger ropeway, large-scale amusement facilities. The boiler, pressure vessel (air bottle), pressure vessel is the pressure type special equipment; Elevator, hoisting machinery, passenger rope and large amusement facilities are special equipment for mechanical and electrical equipment.

- Q: What is the daily routine of the concrete mixing station?

- Concrete mixing station is made by mixing console, materials weighing system, material conveying system, material storage system, control system of five systems and other ancillary facilities of building materials manufacturing equipment, the main principle of work is with cement as cementing material, mixing materials such as sandstone, limestone, coal cinder stirring, finally made into concrete, as the wall materials into construction operation.

- Q: The mixing time of the concrete mixer is in which standard

- Concrete quality control standard gb50164-2011

Send your message to us

Concrete Batching Machine PL1600QB / CE & ISO Certificate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords