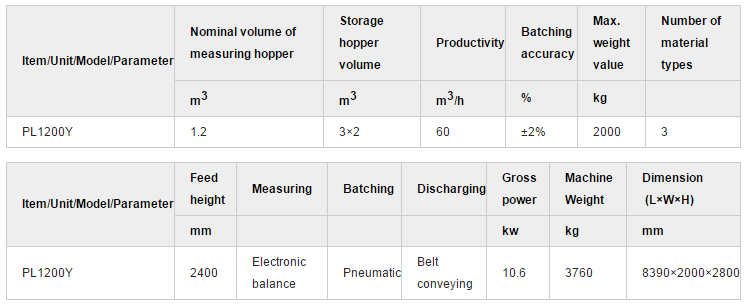

Concrete Batching Machine PL1200Y II/ CE & ISO Certificate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The Technology Center of Yuanyou Heavy Industry is a certified Enterprise Technology Center of Shandong Province; it has a mass of senior R&D engineers, good R&D environment and R&D mechanism which inspirit strong R&D and innovation ability. The center mainly focuses on the technical research, the application of the new technologies and materials, and the development of new products in the fields of construction machinery, building machinery, road machinery, and dry mixed mortar equipment, etc.

The Technology Center is the product and R&D department of Shandong Yuanyou Heavy Industry Science & Technology Co., Ltd., which mainly undertakes the technology and product R&D and technology management. There are five R&D departments, respectively mixing machinery R&D department, dry mortar equipment R&D department, construction machinery R&D department, automation R&D department, and new material R&D department. Every year, there is technology innovation and technical transformation project selected as major project of Weifang city or Shandong province. The recently developed energy-saving and environment friendly air-conveying concrete mixing plant is selected as one of the major technical innovation projects of Shandong province, and it gains the certificate of New Product and New Technology of Shandong Province. The project of “Technical Transformation Project of Energy-Saving and Environment Friendly Air-Conveying Concrete Mixing Plants” with annual output of 200 is approved to be the Top 10 Major Energy-Saving Engineering Project in China and the New Central Government Budgeted Investment Plan Project by National Development and Reform Committee (NDRC). The success of the product lays a solid foundation for the product upgrade and structure optimization, and plays an active role in expanding market and promoting the development of the enterprise. The center always insists on combining the production with research, and successively sets up relationships with colleges and research institutes.

The product is widely used in key projects like various highways, railroads, high-speed railways, airports, ports, bridges, and hydropower stations, as well as commercial concrete mixing station, real estate, and municipal construction. With constantly increasing investment in technological innovation, the company has achieved great achievements and been recognized as “Provincial Enterprise Technology Center” in 2008. The company has 4 research department respectively specializing in mixing, transportation, conveying, and automation.

- Q: The main components of a mixing station

- The conveying system of materials is made up of three parts. Aggregate conveying; There are two ways of conveyance and belt conveyance. The advantage of hopper promotion is that the area is small and the structure is simple. The advantage of belt transport is that the transport is large, efficient and low. The belt conveyor mainly applies to the mixing stations that have aggregate storage, thereby increasing the productivity of the mixing stations. Powder conveying; The powder used in concrete is mainly cement, fly ash and mineral powder. The most commonly used powder conveyors are conveyors of screw conveyors, and the large mixing buildings are carried by pneumatic conveyer and scraper. The advantages of screw transport are simple structure, low cost and reliable use. Liquid transport mainly refers to water and liquid admixtures, which are delivered separately by water pumps

- Q: What is the concept of on-site concrete mixer station

- Concrete mixing station is mainly composed of mixing console, materials weighing system, material conveying system, material storage system and control system of large system and other ancillary facilities. Action: concrete mixing plant is used to concentrate the mixing of concrete, also called concrete precast. Because its mechanization, high degree of automation, productivity is high, and can guarantee the quality of concrete and cement, commonly used in concrete, long duration and site of quantities focus of large and medium-sized water conservancy, electric power, Bridges and other projects. Centralized with the development of municipal construction, stirring, provide commercial concrete mixing station has great advantages, and thus get rapid development, and to promote concrete pumping construction, the mixing, transportation, casting machinery joint operation to create the conditions. Basic introduction: concrete mixing station is mainly composed of mixing console, materials weighing system, material conveying system, material storage system and control system of large system and other ancillary facilities.

- Q: How much concrete is produced per hour by HZS180 concrete mixer?

- Depending on the different areas of the site, the requirement is between 10 and 300, 000, which requires a high level of testing equipment. The cost is relatively higher. The best way is to find a few different test equipment suppliers, according to different manufacturers, equipment, and make a simple quote analysis

- Q: How to choose a good concrete mixer station?

- For simple concrete mixup stations, the overall cost of equipment is much cheaper, because the configuration is different and a lot of configuration is eliminated. But cement weighing cannot save configuration independent water weighing measurement more accurate to efficient, do not use water weighing system can also be mixing concrete, but there is a big hidden trouble. The water weighing system is not suitable for individual water weighing system, and it can reduce the investment of a simple mixing station by about 7, 000 yuan. And shortcomings is not water in the mixing drum of the weighing system and water, time node device can be used to set the water within a certain time interval to churn, but increased water and forced concrete mixer mixing time, still can cause concrete model is not stable. Therefore, although do not use water weighing system can save investment, but will increase the mixing time of concrete and affect the stability of the concrete, so the customer can choose according to oneself circumstance.

- Q: What are the advantages of HZS series of concrete mixing stations

- Concrete mixing plant is composed of ingredients, mixing and electric control system components made sets of fully automatic concrete mixing equipment, and equipped with a separate manual control, automatic fall compensation, sand moisture content of compensation, can automatically accomplish the tank production. The theory of productivity 75 cubic meters/hour, discharging height is 3.8 meters, the storage hopper volume of 8 cubic * 3 warehouse or 4 warehouse, supporting the host is forced JS1500 type and double shaft mixer

- Q: How much concrete is produced by the js1000 type of the concrete mixing station

- The production standard test concrete is not less than 50 cubic meters per hour. But the actual situation is (fully automatic), usually more than 40 cubic meters per hour. The cement productivity would be low by hand. Concrete mixing station, also known as concrete mixing station, concrete mixing station is mainly composed of mixing console, materials weighing system, conveying system, material storage system and control system and so on five big systems and other ancillary facilities. Because building aggregate measurement compared with standing aggregate metering, reduced the four of the intermediate links, and the vertical blanking metering, saved measuring time, thus greatly improving the production efficiency, under the condition of the same model, mixing building production efficiency than mixing plant production efficiency by a third. Concrete mixing station is mainly composed of material storage system, materials weighing system, material conveying system, mixing console and electric control system and other ancillary facilities. The mixing and electrical control system is a key part of the whole equipment.

- Q: What is the special work of the concrete mixing station

- One of the features of the high-performance concrete mixer line is the low water ratio. In order to ensure its liquidity, it must be mixed with an efficient water reducer. Therefore, it is necessary to select cement that is suitable for low water cement ratio. One is the composition of fineness and particles, and the other is the early hydrogenation after the addition of water.

- Q: What is the difference between a concrete mixer and a concrete mixer

- The bone material of the mixing tower is on the top, and the aggregate is measured directly into the mixer. The concrete bin of the commercial concrete station is below, and the bone material is measured and then transported into the mixer after being transported by the inclined belt (which also has some use of the elevator). In a popular way, it is called the building, which is called the second ascent. The steel structure will be larger and the diagonal belt will be relatively longer because of the bone material in the mixing building. But in productivity, the churn is about a fifth higher than the commercial concrete station. In operation, because the inclined belt of the commercial concrete station starts frequently, the energy consumption and the failure rate will increase, and the energy consumption of the mixing building is lower than the failure rate. In the end, because the production capacity of the concrete station is small, the structure is easily disassembled and can be made into a container transfer site, which is suitable for the construction site. The mixing tower is large and high in productivity, and can only be used as a fixed mixer, suitable for the supply of large water projects or large quantities of goods. So customers in the difference between commercial concrete, concrete stand and commodity concrete mixing floor, from aggregate (material), the production efficiency and so on, to choose and buy the right equipment.

- Q: Which staff does the concrete mixing station need?

- Mainly depends on how big is your station, whether can fully staffed, mainly included: general manager, deputy general manager, technology, webmaster, laboratory (deputy) director of the general, the production manager, sales managers, salespeople, scheduling, lab team leader, the operator (inspection), quality inspection, proportioning design, the material inspector technicians, machine operators, resposible, site, monitor of overhaul, maintenance engineer, loadometer, finance, cashier, mixers, pump truck drivers, company drivers, forklift driver, the handyman, chef, etc These are the main people who want to help you.

- Q: What is the daily routine of the concrete mixing station?

- Concrete mixing station is made by mixing console, materials weighing system, material conveying system, material storage system, control system of five systems and other ancillary facilities of building materials manufacturing equipment, the main principle of work is with cement as cementing material, mixing materials such as sandstone, limestone, coal cinder stirring, finally made into concrete, as the wall materials into construction operation.

Send your message to us

Concrete Batching Machine PL1200Y II/ CE & ISO Certificate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords