Composite Timber Decking from factory and made in CHINA

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

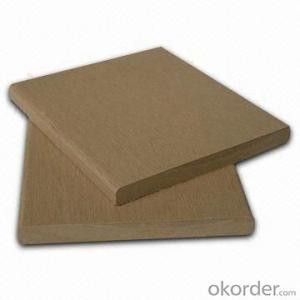

一. Structure of Composite Timber Decking

Item | Composite Timber Decking-- China 10 Years Experience Composite Decking Suppliers |

Material | Wood Plastic Composite |

Color | Cedar, Coffee, Brown, Black, Dark gray, Light gray, Red wood, Red pine, Yellow, or adjusted to customer's requirement |

Surface | Groove, Wood Grain, Sanding |

Length | 2.2m/pc, 2.9m/pc, 5.4m/pc |

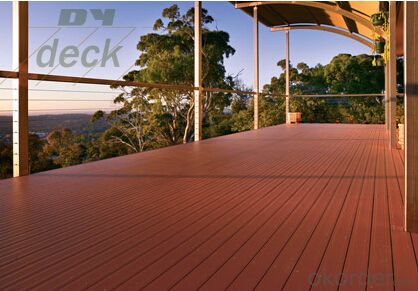

Application | Terrace, Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Playground |

Packing | PE Film + WPC Pallet (length of 0-2.2m) or Wood Pallet (length>2.2m) optional |

Certificate: | CE, SGS, CMTL |

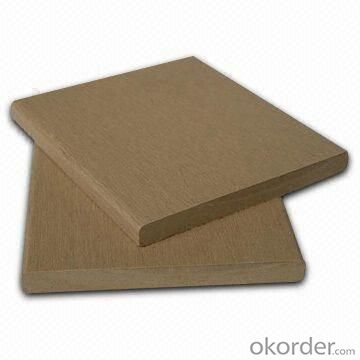

二.Main Features of Composite Timber Decking

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

三. Composite Timber Decking Images

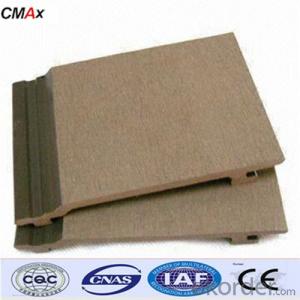

四. Composite Timber Decking for outdoor Specification

Name | Cheap Composite Decking sutibale for outdoor |

Size | W*H=145*30 mm, can be customized |

Length | 2200mm, 2800mm, 4000mm, Customized |

Material | Wood Powder, HDPE, Additives |

Surface Finishing | Sanding, Brushing, Wood grain |

Certification | CE, Reach, Intertek, SGS, ISO, FSC |

Range of Application | Outdoor Flooring, Garden, Balcony, Terrace, Pool Surrounds, Boardwalk, Playground… |

五.FAQ of Composite Timber Decking

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: The home is all ceramic tile or plastic floor

- Unwanted。 In winter, you can carpet in the bedroom. I hope my answer can help you

- Q: How many yuan per square meter of plastic floor

- Please understand Shanghai Hu Mei plastic floor for the sports ground facilities, good floor to prevent injuries, foot comfort. Shanghai, Shanghai, the United States and the United States and the United States and the United States and the United States and the United States and the United States and the United States and the United States and the United States and the United States and the United States and the United States and the United States and. Stable regular rebound to the ground to achieve the best comfort

- Q: Can I have a white mat?

- The original mats at the seams overlap 20mm, and tape sealing, although also can achieve similar waterproof effect, but the cushion thickness of 2mm or so, the overlap will have high low, easy to produce noise floor installation. The thickness of plastic film is only about 0.1mm, although the overlap will not produce high and low, no effect on the pavement.

- Q: Home decoration can use plastic floor it?

- Due to the unique advantages of PVC floor and huge development prospects, many domestic enterprises also began to get involved in the PVC flooring industry, through the introduction of technology and equipment, absorbing research and innovation, now part of the enterprise in PVC sheet and PVC composite sheet has made considerable progress, to produce high-quality PVC floor, but generally speaking PVC membrane production technology is still not perfect, still need to. Sales in the market PVC floor, especially around some of the building materials City gathered a lot of small manufacturers, they are mainly for the low-end market, in order to meet the consumer price pressure is very low, the natural quality can not be guaranteed. It also caused the phenomenon of poor quality PVC floor flooded the market, people naturally have misconceptions on the PVC floor. In order to protect the interests of consumers, we recommend the use of well-known brands or products, there is an old saying in China, "no good cheap goods, good goods are not cheap," or very reasonable.

- Q: Plastic floor paper how much a square

- On the floor of the material as well as any special design requirements (requirements and price proportional)

- Q: How to spread the plastic floor?

- On the ground roughness requirements are higher, the best time to install the floor glue

- Q: What are the differences between plastic floor and floor tiles

- Plastic floor is the main material for PVC resin, and the composite floor is composed of the wear-resistant layer five layer structure, through a special process, with heat resistance, moisture resistance and deformation, anti-aging, antibacterial, mute, abrasion resistance, fire retardant etc.. Plastic floor, also known as PVC floor, mainly in PVC materials (polyvinyl chloride) as raw material for the production of ground decorative materials. Some people call it plastic floor, floor board, floor glue, floor leather, a variety of names, different regions are also different names

- Q: Plastic floor can be spread in the bathroom

- A commercial floor (children's glue) children's floor (PVC floor) plastic floor1, commercial floor material PVC (real name: PVC floor)2, commercial floor PVC wood material

- Q: What is the price per square metre of plastic floor?

- And the price of this plastic floor in accordance with the use of different location, the difference between the laying of a slightly larger, then there will be some differences in prices. This is a common phenomenon.

- Q: What is the role of badminton PVC plastic floor

- The glass fiber reinforced layer plays the role of stabilizing the size of the site and prolonging the service life, which makes the floor never shrink, the performance is more stable, and the athletes can play a better level.

Send your message to us

Composite Timber Decking from factory and made in CHINA

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords