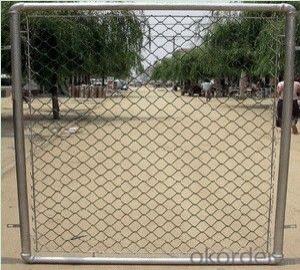

Common Chain Link Fence

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Type: | Place of Origin: | Hole Shape: | |||

| Model Number: | Frame Material: | Metal Type: | |||

| Pressure Treated Wood Type: | Frame Finishing: | Feature: | |||

| Item: | Material: | Assortment: | |||

| Mesh: | Wire dia: | Length: | |||

| Height: | zinc coating: | Color: | |||

Packaging & Delivery

| Packaging Detail: | woven bags in two edge of rolls |

| Delivery Detail: | 15-25days |

Specifications

Chain link fence

1.Material: low carbon steel wire,stainless steel wire, PVC coated wire.

2.Wire dia 0.2mm~5.0mm

- Q: How does steel wire mesh perform in load-bearing capacity?

- Steel wire mesh has excellent load-bearing capacity due to its strong and durable nature. It can effectively distribute and bear heavy loads without deforming or breaking, making it suitable for various applications such as construction, reinforcement, and fencing.

- Q: What are the different thickness options available for steel wire mesh?

- There are several different thickness options available for steel wire mesh, depending on the specific application and requirements. The thickness of steel wire mesh is typically measured in gauge or wire diameter. Common thickness options for steel wire mesh range from 4 gauge (5.19 mm or 0.2043 inches) to 30 gauge (0.25 mm or 0.0098 inches). However, it is important to note that the thickness can vary even within these ranges, as different manufacturers may offer slightly different wire diameters. The choice of thickness depends on various factors such as the intended use of the wire mesh, the level of strength and durability required, and the size of the openings needed for the specific application. For example, a thicker gauge wire mesh would be suitable for heavy-duty applications such as industrial screens or fencing, where strength and resistance to impact are important. On the other hand, a thinner gauge wire mesh may be suitable for more lightweight applications such as insect screens or decorative purposes. It is advisable to consult with a reputable supplier or manufacturer to determine the most appropriate thickness option for your specific needs. They can provide guidance based on the desired application, budget, and other considerations to ensure that you select the most suitable thickness for your steel wire mesh.

- Q: Is steel wire mesh suitable for outdoor applications?

- Indeed, steel wire mesh proves to be highly appropriate for outdoor applications. Renowned for its robustness and sturdiness, steel wire mesh emerges as an exceptional alternative for outdoor utilization. It possesses the ability to endure adverse weather conditions, including strong gusts of wind, torrential rainfall, and extreme temperatures, without succumbing to any harm or corrosion. Not only that, steel wire mesh exhibits resistance against bothersome pests, rodents, and insects, rendering it an ideal choice for outdoor perimeters, enclosures, and protective barriers. Moreover, steel wire mesh can undergo galvanization or be coated with materials such as PVC, thereby fortifying its anti-corrosion properties and extending its lifespan, thereby rendering it even more suitable for outdoor applications.

- Q: Does steel wire mesh rust?

- Yes, steel wire mesh can rust. Rust is the result of the oxidation process that occurs when iron or steel is exposed to moisture and oxygen. If the steel wire mesh is not properly coated or protected, it can be susceptible to rusting over time. However, there are various methods to prevent or minimize rusting, such as galvanizing the steel wire mesh or applying a protective coating. These measures can significantly extend the lifespan of the mesh and ensure its durability.

- Q: How does steel wire mesh perform in high-pressure water jetting applications?

- Steel wire mesh performs well in high-pressure water jetting applications. It is highly durable and strong, allowing it to withstand the force of high-pressure water jets without breaking or deforming. The mesh's small openings and tightly woven structure provide effective filtration, preventing debris and particles from passing through and potentially damaging the equipment or clogging the water jet nozzles. Additionally, steel wire mesh is resistant to corrosion and can withstand exposure to water and other environmental elements, making it suitable for long-term use in water jetting applications. Overall, steel wire mesh is an excellent choice for high-pressure water jetting applications due to its strength, durability, filtration capabilities, and resistance to corrosion.

- Q: Can steel wire mesh be used in electrical applications?

- Yes, steel wire mesh can be used in electrical applications. It is commonly used for grounding purposes, providing protection against electromagnetic interference, and as a conductor in various electrical circuits.

- Q: How does steel wire mesh perform in terms of resistance to weathering?

- Steel wire mesh is known for its exceptional resistance to weathering. Its composition, consisting of sturdy and corrosion-resistant steel, allows it to withstand various weather conditions such as rain, snow, heat, and UV exposure. Unlike other materials, steel wire mesh does not warp, crack, or degrade when exposed to these elements. The galvanization process further enhances its weather resistance. Galvanization involves coating the steel wire mesh with a layer of zinc, which acts as a barrier against moisture and prevents rusting. This additional layer makes the mesh even more durable and extends its lifespan. Steel wire mesh also performs well in terms of resistance to extreme temperatures. It does not become brittle in cold weather or lose its structural integrity in high temperatures. This makes it suitable for a wide range of applications, including outdoor fencing, construction projects, and agricultural uses. Furthermore, steel wire mesh is highly resistant to wind and impact. Its strong and flexible nature enables it to withstand strong gusts without bending or breaking. This makes it an ideal choice for applications where wind loads are a concern, such as in coastal areas or high-rise buildings. Overall, steel wire mesh is an excellent choice for outdoor applications due to its exceptional resistance to weathering. Its ability to withstand various weather conditions, galvanized coating, and resistance to extreme temperatures and wind make it a reliable and durable option for a wide range of projects.

- Q: How is steel wire mesh used in reinforcement of chemical plants?

- Steel wire mesh is commonly used in the reinforcement of chemical plants due to its excellent strength and durability. It is primarily used in the construction of concrete structures within the plant such as walls, floors, and ceilings. Chemical plants typically house equipment and machinery that generate high levels of heat, pressure, and corrosive substances. Steel wire mesh is highly resistant to these harsh conditions, making it an ideal choice for reinforcement. The mesh is typically embedded within the concrete structure, providing additional support and stability. It helps to distribute the load evenly across the structure, minimizing the risk of cracks and structural failures. This is particularly important in chemical plants, where the integrity of the structure is crucial to ensure the safe operation of the plant and to prevent any potential leaks or accidents. Furthermore, steel wire mesh is also effective in preventing the propagation of cracks. In the event of a crack forming, the mesh acts as a barrier, preventing the crack from spreading and compromising the structure's strength. This is especially valuable in chemical plants where the containment of hazardous materials is of utmost importance. Additionally, steel wire mesh can also be used in the reinforcement of concrete pipes, tanks, and other structures that are commonly found in chemical plants. The mesh helps to enhance the structural integrity of these elements, making them more resistant to the corrosive nature of the chemicals being handled. Overall, the use of steel wire mesh in the reinforcement of chemical plants plays a critical role in ensuring the safety and longevity of the structures. Its strength, durability, and resistance to harsh conditions make it an essential component in the construction and maintenance of these facilities.

- Q: How does steel wire mesh perform in fire resistance?

- Fire resistance is typically a strong suit for steel wire mesh. Its metal composition provides it with a high melting point and robust structural integrity, enabling it to endure high temperatures for extended durations. This renders it a dependable choice for situations that demand fire resistance. During a fire, steel wire mesh acts as a barrier, obstructing the propagation of flames and minimizing heat-induced damage. It effectively confines the fire to a specific area, allowing more time for evacuation or the implementation of fire suppression measures. Furthermore, steel wire mesh does not release toxic fumes or emit harmful gases when exposed to fire, ensuring the safety of individuals in its vicinity. This characteristic is especially crucial in buildings where materials with fire-resistant properties are indispensable for safeguarding occupants and minimizing property destruction. Moreover, steel wire mesh is frequently utilized in fire-resistant doors, windows, and ventilation systems due to its ability to withstand intense heat and prevent the passage of fire and smoke. Its durability and fire resistance make it an appropriate option for various industrial, commercial, and residential applications. However, it is important to note that the fire resistance of steel wire mesh can vary based on factors such as mesh size, thickness, and adherence to specific fire ratings. Therefore, it is vital to carefully select the appropriate type of steel wire mesh that complies with the required fire safety standards for a given application. In conclusion, steel wire mesh excels in terms of fire resistance owing to its high melting point, structural integrity, and ability to confine flames. Its usage in fire-rated doors, windows, and ventilation systems ensures the safety of occupants and helps prevent the spread of fire and smoke. Nevertheless, it is crucial to choose the right type of steel wire mesh that meets the necessary fire safety regulations.

- Q: Is steel wire mesh resistant to staining?

- Yes, steel wire mesh is generally resistant to staining. The steel wire used in the mesh is typically coated or treated with a protective layer to prevent corrosion and enhance its stain resistance. This protective layer can be in the form of galvanization, PVC coating, or epoxy coating, among others. These coatings create a barrier between the steel wire and external elements such as moisture, chemicals, and environmental factors that can cause staining. However, it is important to note that the level of stain resistance may vary depending on the specific type of steel wire mesh and the nature of the staining agent. In some cases, certain strong chemicals or prolonged exposure to harsh environmental conditions may still cause minor discoloration or staining on the mesh. Regular cleaning and maintenance can help to minimize any potential staining and keep the steel wire mesh in optimal condition.

Send your message to us

Common Chain Link Fence

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords