Commercial Packaging Tape - Double Sided Tissue Tape with Solvent Based Adhesive, Yellow Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

The Double Sided Tissue Tape is of tissue as the carrier, coating with hot melt adhesive, water based acrylic, solvent based acrylic. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

The thickness of the tape can be customized.

General purpose of Double Sided Tissue Tape: widely used for bonding, fixing for leather, foam, sponge, garment, shoe, luggage, plastic, paper splicing and stationery.

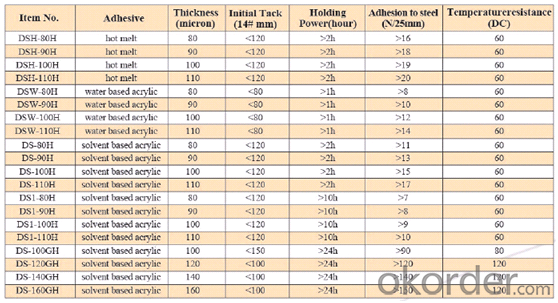

Typical Physical Reports of Double Sided Tissue Tape

Packaging Detail

The thickness of the tape can be customized.

Cut Roll: As per customer’s requirements

Log Roll: Length 1000mm; width: 1050mm, 1260mm, 1040mm..

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Double Sided Tissue Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: 2014, how can I sell the tape better?

- Fourth, the background of your company must say company influence and company history,Fifth, the market prospects and profit margins, regardless of the price of your products is how much of that is not a problem, and if you have a small list of hands, you can put the list to be introduced to customers, these are my experience to sell, can only give you a reference, are different for each personal selling, to try to know,

- Q: Are there any special considerations when using packaging tape for fragile items?

- Yes, there are definitely special considerations when using packaging tape for fragile items. When packaging fragile items, it is important to choose a tape specifically designed for this purpose. Look for packaging tape that is labeled as "fragile" or "handle with care" as these tapes are usually reinforced with additional strength and have special features to protect fragile items. Here are some specific considerations when using packaging tape for fragile items: 1. Strength and durability: Fragile items require extra protection, so it is crucial to use a tape that is strong and durable. Look for packaging tape that is made from high-quality materials, such as reinforced fiberglass or heavy-duty polypropylene, to ensure it can withstand the weight and pressure without tearing or breaking. 2. Cushioning and padding: Fragile items are prone to damage from impact, so it is recommended to use packaging tape that provides cushioning or padding. Some tapes come with built-in bubble wrap or foam padding, which helps absorb shocks and protect delicate items from breaking during transit or handling. 3. Adhesive quality: The adhesive quality of the packaging tape is another important consideration. Fragile items might require longer transit times, and the tape needs to stay securely in place throughout the journey. Look for packaging tape with a strong adhesive that can adhere well to various surfaces, including cardboard boxes, plastics, or glass. 4. Easy removal: Fragile items often need to be unpacked delicately, so it is essential to use packaging tape that can be easily removed without leaving any sticky residue or damaging the item. Some tapes are designed to have a low-tack adhesive, making them easier to peel off without any hassle. 5. Clear visibility: It is crucial to ensure that fragile items are clearly marked to alert handlers and delivery personnel. Using packaging tape that is brightly colored or labeled with a "fragile" message can help draw attention and promote careful handling. In summary, when using packaging tape for fragile items, it is essential to choose a tape that is strong, durable, provides cushioning, has a high-quality adhesive, and is easy to remove. These considerations will help protect fragile items from damage during shipping or handling.

- Q: Are there any eco-friendly options for packaging tape?

- In today's market, there are various eco-friendly options for packaging tape. Typically, traditional packaging tapes are made from plastic materials like polypropylene or PVC, which are harmful to the environment and not biodegradable. However, there have been developments in creating eco-friendly alternatives to tackle this issue. Some of these options include: 1. Packaging tape made from paper: These tapes are crafted from renewable resources like paper and natural adhesives. They are both biodegradable and compostable, making them a sustainable choice for packaging requirements. 2. Gummed paper tape, also known as water-activated tape: This type of tape is made from paper and requires water to activate the adhesive. It forms a strong bond when applied to boxes and provides tamper-proof sealing. Additionally, water-activated tape is biodegradable and can be recycled along with the packaging it is used on. 3. Biodegradable and compostable tape: These tapes are manufactured using plant-based materials such as cellulose or polylactic acid (PLA). They are designed to naturally break down over time, minimizing their impact on the environment. Some options are certified as compostable, meaning they can be added to compost piles or sent to composting facilities. 4. Recycled plastic tape: Although traditional plastic tapes are not environmentally friendly, there are recycled plastic tape options available in the market. These tapes are produced using recycled plastic materials, reducing the demand for new plastic and promoting a circular economy. When searching for eco-friendly packaging tape, it is crucial to consider certifications such as the Forest Stewardship Council (FSC) for paper-based tapes or the Biodegradable Products Institute (BPI) certification for compostable tapes. By opting for these alternatives, individuals and businesses can minimize their environmental impact and contribute to a more sustainable future.

- Q: Can packaging tape be used for sealing paper bags?

- Yes, packaging tape can be used for sealing paper bags.

- Q: Can packaging tape be used for sealing packages with medical or pharmaceutical products?

- Indeed, packaging tape can certainly serve as a means to seal packages containing medical or pharmaceutical items. Nonetheless, it is crucial to take into account the precise requirements and regulations pertaining to packaging within the medical and pharmaceutical sectors. Such industries often uphold rigorous standards concerning packaging materials, aiming to guarantee the safety, soundness, and adherence to regulatory guidelines of the products. Consequently, it is advisable to opt for packaging tape specifically formulated and authorized for use in medical or pharmaceutical contexts. These tapes are typically composed of moisture-resistant and tamper-proof materials, ensuring a robust seal to safeguard the package's contents. By utilizing approved packaging tape, the quality and integrity of medical or pharmaceutical products can be preserved throughout storage and transportation.

- Q: A tape of 2.5 cm thick, about how many meters

- Take a look at how thick the film is and how much silk it reaches

- Q: The production of transparent tape material is what to do

- The base material of the sealing adhesive tape is BOPP film.BOPP is a very important flexible packaging material, and has been widely used. BOPP film is colorless, odorless, tasteless, non-toxic, and has high tensile strength, impact strength, rigidity, toughness and good transparency. It is a high quality substrate for making transparent sealing tape. BOPP film has low surface energy, and it needs corona treatment before gluing or printing. However, the BOPP film has good printing adaptability after corona treatment. It can be printed by printing and has a beautiful appearance, so it is often used as the surface material of composite films. BOPP film is also inadequate, such as easy accumulation of static electricity, no heat sealing and so on. In the high-speed production line, BOPP film is easy to generate static electricity. Electrostatic eliminator is necessary. In order to obtain the BOPP heat seal film, can be on the surface of BOPP film after corona treatment coating heat sealing resin glue, such as PVDC, EVA latex latex, can also be coated with solvent glue, coating or extrusion method can be applied to the production of extruded composite heat sealing film BOPP. The film is widely used in bread, clothing, footwear and other packaging, and cigarettes, books cover packaging. The tear strength of BOPP film increases after stretching, but the secondary tearing strength is very low. Therefore, no cut can be left at the ends of the BOPP film, otherwise the BOPP film is easy to tear when printed and compounded. BOPP coated self-adhesive, we can produce our commonly used sealing tape, tape sealing tape, is a larger amount of BOPP market.

- Q: What is packaging tape?

- Packaging tape, specifically designed for sealing and securing packages and boxes, is a form of adhesive tape. It is widely used in industries, shipping companies, warehouses, and households to guarantee the proper sealing and protection of packages during transportation or storage. This tape is typically manufactured from durable materials like polypropylene or polyester, which provide tear resistance and strong adhesion. It comes in various widths and thicknesses to accommodate different package sizes and weights. While it is commonly transparent or brown, it can also be found in different colors or patterns for aesthetic purposes or to distinguish between package types. Overall, packaging tape is an indispensable tool for ensuring the safety and security of packages during transit or storage.

- Q: How does packaging tape differ from masking tape?

- Packaging tape and masking tape are two different types of tapes that serve different purposes and have distinct characteristics. Packaging tape is specifically designed for sealing and securing packages or boxes. It is commonly used in shipping and packaging industries. Packaging tape is typically made from a strong and durable material, such as polypropylene or PVC, which provides excellent adhesion and resistance to tearing or splitting. It is known for its high tensile strength, which ensures that the package remains sealed during transit or storage. Packaging tape also usually has a strong adhesive that sticks well to various surfaces, including cardboard, plastics, and metals. It is available in different widths and lengths to accommodate different packaging needs. On the other hand, masking tape is primarily used in painting and DIY projects. It is made from a thinner and less durable material, such as crepe paper, and has a less aggressive adhesive compared to packaging tape. The main purpose of masking tape is to create clean, straight lines and protect surfaces from paint or other liquids during painting jobs. Masking tape can be easily applied and removed without leaving residue or causing damage to the surface. It is also known for its ability to conform to uneven surfaces, allowing for precise masking and detailing work. In summary, packaging tape is designed for secure sealing and packaging of boxes and packages, while masking tape is primarily used for painting and protecting surfaces. Packaging tape is stronger, more durable, and has a stronger adhesive, while masking tape is thinner, more flexible, and can be easily removed without leaving residue.

- Q: Is packaging tape safe to use on painted surfaces?

- Yes, packaging tape is generally safe to use on painted surfaces. However, it is recommended to test a small, inconspicuous area first to ensure that the tape does not damage or peel off the paint.

Send your message to us

Commercial Packaging Tape - Double Sided Tissue Tape with Solvent Based Adhesive, Yellow Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords