Colorful Coating Aluminum Composite Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Colorful Coating Aluminum Composite Panel

Product Description

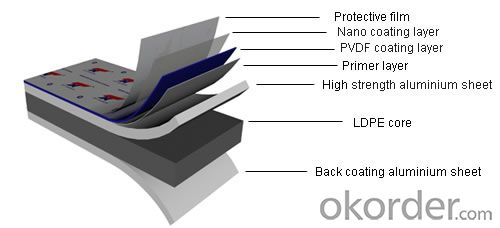

| Name | Colorful Coating Aluminum Composite Panel | |

| PVDF | 4*0.4mm | Most Popular In The World For Outdoor Decoration |

| 4*0.5mm | Best For Outdoor Decoration In General | |

| 4*0.3mm | Economy Also Meet Requirement For Outdoor Decoration | |

| 3*0.3mm | Popular For Indoor Decoration In Commercial Building | |

| 4*0.5mm | Superior Fireproof Performance On The Basis Of The Best Specification | |

| Fireproof | ||

| PE | 3*0.3mm | Most Popular In The World For Indoor Decoration |

| 3*0.21mm | Economy For Indoor Decoration In General | |

Profermance:

| Dimensional Tolerances | Thickness(mm) | ± 0.2 |

| Width(mm) | ± 2 | |

| Length(mm) | ± 3 | |

| Diagonal(mm) | ± 5 | |

| Thermal Expansion | 2.4mm/m at 100 º C temp difference | |

| Aluminum Thickness(mm) | ± 0.02 | |

| Surface Properties | Pencil Hardness | > HB/> 2H |

| Temperature Resistance | -50 º C to +80 º C | |

| Impact strength (kg. cm) | 50 | |

| Boiling Resistance | Boiling for 2 hours without change | |

| Acid Resistance | Immerse Surface in 2% HC1 for 48 hours without change | |

| Alkali Resistance | Immerse Surface in 2% NAOH for 48 hours without change | |

| Oil Resistance | Immerse Surface in 20# engine oil for 48 hours without change | |

| Solvent Resistance | Cleaned 100 times with dimethylbezene without change | |

| Cleaning Resistance | Over 1000 times without change | |

| Peel Strength 180 º C | 180oC> 5 newton/mm | |

| Product Properties | Sound Absorption NRC | 0.05 |

| Sound Attenuation RW db | 23/24/25 | |

| Water Absorption % by volume | 0.0047/0.0057/0.0012 | |

| Core Composition | LDPE Polyethylene, Non- Combustible Material |

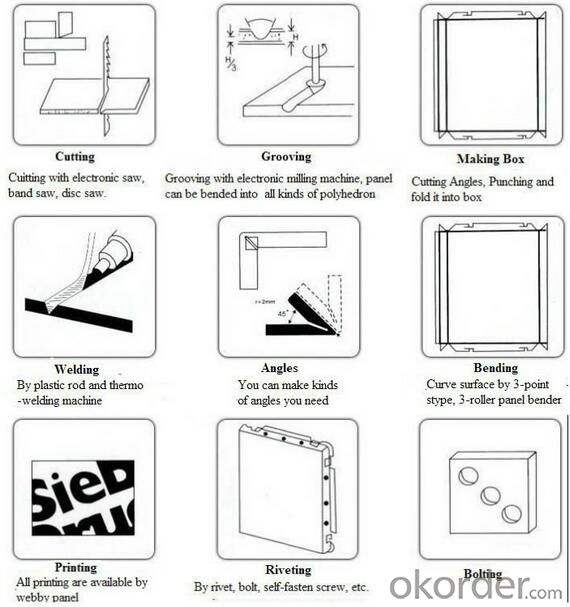

Process:

Applications:

1) Building exterior curtain walls

2) Decoration and renovation additions for old buildings

3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

4) Shop door decoration

5) Advertisement board display platforms and signboards

6) Wallboards and ceilings for tunnels

7) Industrial materials and materials for vehicles and boats

Package

FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q:What is the material of your products?

A:The material are mainly color coating Aluminum and color coated steel and aluminum composite panel.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

Q:Can you make new mold with customized size I need?

A: YES, We can make mold for you .

Q:Can you provide OEM &ODM service?

A. Sure. We can help you print or emboss your logo. We're good at this and I always provide this service for home or abroad company

- Q: Aluminum-plastic plate of the thick aluminum thickness can be thicker?

- The aluminum thickness of the aluminum-plastic plate can be made into a different thickness depending on the actual use of the user. In general, the aluminum plate thickness of the thickest aluminum can do 50 silk, which is in the whole board thickness of not less than 4mm in the case, if the whole board thickness is too thin, then it can not do so thick The aluminum is thick. Buy good quality aluminum-plastic board, recommended Astra aluminum plate.

- Q: Which bathroom cabinet is better? What kind of material is better

- Dear haluo23 Hello, you can go to the [Santo hotel supplies] one-stop shopping service platform to browse the bathroom cabinet. They have a wide variety of furniture products, you have all the above you want a variety of household items, home appliances, bathroom, bedding. Are very complete. And heard this year they were rated as the top ten selection of HC network in the most promising one-stop shopping service platform. Is the most famous one-stop integrated procurement services hotel supplies provider! I believe that their product quality and service are very word of mouth in the industry, my dear you can go to contact their customer service, to understand their own when the price is enough to buy their own bathroom cabinet, I believe their customer service will be warm to help You solve!

- Q: What are the benefits of aluminum-plastic board prices?

- In foreign countries, there are many kinds of names of aluminum-plastic plates, called aluminum composite panels (Aluminum Composite Panels); called aluminum composite materials (Aluminum Composite Materials); in many countries in Europe, said aluminum-plastic plate for the Alucobond, A trademark name for a plastic board. Foreign production of aluminum-plastic plate business is not a lot, but the scale of production are great. Famous in the Swiss-based Alusuisse company, the United States Reynolds Metals, Japan's Mitsubishi, South Korea Daming, Taiwan auspicious and so on. Domestic well-known enterprises have Ningbo love good building materials.

- Q: Will the aluminum plate is flammable?

- The conventional aluminum-plastic plate from the fire to judge this point of view, is flammable, not the flame level.

- Q: Seeking a list of well-known aluminum-plastic panel manufacturers in South China. Thank you for the best with the corporate website

- Know you want high-end or low-end

- Q: Which brand is better?

- OKorder has called "workers"

- Q: Aluminum-plastic board dirty what cleaning

- clean aluminum-plastic panels in accordance with the left to right, from top to bottom in the order.

- Q: How to judge the market now on the advantages and disadvantages of aluminum-plastic composite panels

- Whether it can easily tear the aluminum down, inside the board can not point

- Q: These two kinds of longer life with the customer? The The

- Do the material of the door if the life is not as good as you can get how much money to do aluminum-plastic board FC can guarantee 10 years if the color of the polyester deep time can not guarantee too long if the light can guarantee 3 to 5 years

- Q: Which brand of aluminum veneer is good, where to find suppliers?

- Can not say which brand is good, and now there is no brand, do the same way, mainly to see the price, and then look at the region, such as if you in Anhui, Jiangxi, you can run the factory in Guangdong, it is impossible , Is certainly near to find,

Send your message to us

Colorful Coating Aluminum Composite Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords