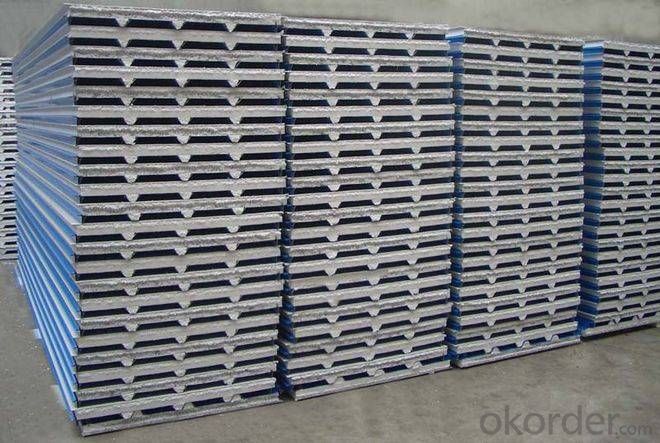

Color steel lowe cheap wall paneling,polystyrene foam eps wall sandwich panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Hebei China (Mainland) | Brand Name: | SWMetal | Model Number: | SWEPSW |

| Panel Material: | Metal | Type: | EPS Sandwich Panels,EPS Foam Boards | thickness: | 50,75,100,150,200 mm |

| color: | all RAL Color | material: | EPS Sandwich wall panel | Width: | 950 mm |

| length: | 1-11.8 meter | surface steel color: | all RAL color |

Packaging & Delivery

| Packaging Detail: | Standard export packing,plastic film |

| Delivery Detail: | 15-20days |

Specifications

lowe cheap wall paneling

1.Thickness of steel sheet: 0.3-0.8mm

2. Thickness of sandwich: 50-200mm

3.Width 950/960 mm

Product Description

Color steel low cost wall panels,polystyrene foam eps wall sandwich panel

1.Thickness of steel sheet: 0.3-0.8mm

2. Thickness of sandwich: 50-200mm

3. Density: 8-30kg\m3

4. Color: K7 RAL Card

Specification of EPS:

Name: EPS (Expandable Polystyrene) Sandwich Panel | |

Thickness of facing plate | 0.3mm-0.7mm or custom-tailor |

Thickness of sandwich | 50mm-150 mm or custom-tailor |

Type: | Expandable Polystyrene |

Basic steel | galvanized steel, Galvanized steel and stainless steel |

Finish | Galvanized, Powder-coated with PE/HDP/PUDF, Stainless steel with brushed/mirrored. |

Length (mm) | Tailored as per client requirement due to continuous forming production. |

Product features:

1. Heat and sound insulation. Temperature suitable for PU ranges from -200 centigrade to 150 centigrade.

2. Light weight, water-proof, Good chemical resistance and seismic resistance, anti-corrosion etc.

3. Energy conservation, environment protection, economical, good structure, easy to installation.

Usage:

EPS is widely used in construction, heat preservation, packaging, frozen, daily necessities, industrial casting, etc. It can also be used to display the assembly places, commodity cabinet, signs and toys manufacture.

It mainly applies to the wall exterior insulation, heat preservation, floor heating in the wall to adapt national building energy requirements.

- Q: Q235 sheet of the label

- Q235 hot-rolled plate: the molecular standard for the standard: 3-GB / T 709-88; denominator for the acceptance criteria: Q235-GB / T 700-88 Q235 cold-rolled plate: the molecular standard for the standard: 3-GB / T 708-88; denominator for the acceptance criteria: Q235-GB / T 700-88

- Q: Cabinet door environmental protection grade how to divide

- European environmental standards are divided into E2, E1, E0 three grades, which E0 level environmental protection cabinet formaldehyde emission at least, so the whole cabinet is the most direct way to identify whether the environmental protection cabinet is to see whether the brand cabinet environmental commitment, if necessary, Of the environmental rating certificate, the most important thing is to see the store's environmental testing report, which have seen more can be more at ease. E1, E0 level is the European countries based on the content of free formaldehyde in wood-based panels to divide, but also China's home use of artificial plate standards. Domestic brand cabinets are widely used to achieve the European E1 standard green sheet, has reached the cabinet environmental safety and safety requirements, and environmental standards higher E0 grade sheet, because it does not contain green moisture and adhesives, its toughness and moisture resistance relative Low, easy to tide fracture, generally used as a furniture substrate, not suitable for use in the kitchen humid environment. At the same time, because the E0 level cost higher than the E1 level two or three percent, therefore, really use E0 level plate manufacturing cabinet manufacturers rarely. Many manufacturers have claimed that their sheet is E0-class environmental standards of the plate, in fact, there will inevitably be speculation in the composition of the inside.

- Q: What are the advantages of nylon plates compared to other plastic sheets?

- The nylon series is the most important engineering plastic. The product is widely used, covering almost every area, is the five most widely used engineering plastics varieties Nylon board according to the production process is divided into two kinds of extrusion and casting. Extrude the nylon plate 1, nylon 6 (white): The material has the most comprehensive performance, including mechanical strength, stiffness, toughness, mechanical shock absorption and wear resistance. These features, coupled with good electrical insulation and chemical resistance, make nylon 6 a "universal grade" material for the manufacture of mechanical structural parts and maintainable parts. 2, nylon 66 (cream): Compared with nylon 6, its mechanical strength, stiffness, heat and wear resistance, creep resistance better, but the impact strength and mechanical damping performance degradation, very suitable for automatic lathe Machining. 3, nylon 4.6 (reddish brown): Compared with ordinary nylon, nylon 4.6 is characterized by strong rigid retention, good creep resistance, in a wide temperature range, more heat aging, therefore, nylon 4.6 for Nylon 6, nylon 66, POM and PET in the stiffness, creep resistance, heat aging, fatigue strength and wear resistance can not meet the requirements of the "higher temperature field" (80 -150 ℃) 4, nylon 66 + GF30 (black): Compared with pure nylon 66, this nylon filled with 30% glass fiber reinforced, its heat resistance, strength, stiffness. Creep resistance and dimensional stability, wear resistance and other properties have improved, it is the maximum allowable use of high temperature. 5, nylon 66 + MOS2 (gray black): This nylon filled with molybdenum disulfide, compared with nylon 66, its rigidity, hardness and dimensional stability has improved, but the impact strength has declined, molybdenum disulfide Of the grain formation effect to improve the crystal structure, so that the material bearing and wear resistance are improved.

- Q: What kind of plates are used for building models? In addition to the abs board kt board

- Learn Fu board (sound) 1mm, 2mm, 5mm thick, easy to stick easy to stick. Abs only for machine processing, kt board is generally used to do the model floor or base model, because the edge is very rough and the texture is not good. Occasionally, cardboard and flight templates are used, depending on your needs

- Q: What are the characteristics of wood?

- Light weight, high strength than high, good elasticity, impact resistance, easy processing

- Q: Kunming fly forest board and love grid plate which a good?

- Can these two be better than that? One is imported from Germany, one is Kunming, the core can see the gap

- Q: How to color the plate after carving

- First with the newspaper accounted for four weeks, leaving the word, you can spray later.

- Q: TR90 memory board frame is what?

- In fact, there is no such frames, TR90 frame with the plate is different. 1, from the material comparison: TR90 frame is the use of nylon material (also known as nylon 12 or PA12), is the most popular ultra-light frame material, with light weight, good toughness, super safety and other characteristics, with super Flexibility, wear in motion will never break. (Except fake and shoddy products). Plate frame is the use of acetate fiber or propionic acid fiber. Injection molding or suppression of grinding production. 2, the process comparison: TR90 frame process complex, the injection of glass factory and spray paint process requirements are relatively high. Plate rack: Although the plate rack less painting, but in the work than the TR90 frame process to be much more, more complex process. 3, the use of comparison: TR90 Frame: light weight, comfortable to wear, more secure, more difficult to deformation. The only drawback is that it will fade. Plate frame: the same size of the frame relative to the TR90 frame will be more weight, the bridge of the nose will have the feeling of oppression, comfort is not as TR90 frame, flexibility and safety than the TR90 frame slightly worse. The advantages of three-dimensional sense of strong, three-dimensional edges and corners of the TR90 frame can not be compared, but also not out of color. )

- Q: If you have any questions, please tell us. The Thank you

- In the road on the 7th there really is Kaida board to sell, my house some time ago to decorate in his home to buy, the quality is not generally good, the price is better than others

- Q: Comparison of fire and water of the plate

- Solid wood is the best, the most upscale

Send your message to us

Color steel lowe cheap wall paneling,polystyrene foam eps wall sandwich panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords