Color coated steel coils white color,green color,red color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

colour coated steel

painting colour steel , zinc coated steel , lead coated steel

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | DX51D,SGCC,SPCC,CGCC | Thickness: | 0.17-1.5mm |

Place of Origin: | Taian China (Mainland) | Brand Name: | HengJi | Model Number: | HJ |

Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | RAL color cremated, oiled, skin passed |

Application: |

building metal roofing components,house appliance | Width: | 914-1250mm | Length: | customized |

price: | favorable price | Our Customers | Steel force, Stemcor, Duferco, Samsung , G&G,Hyosun |

Packaging & Delivery

Packaging Detail: | standard export packing or customized |

Delivery Detail: | 15 days after prepayment |

Specifications:

galvanized steel coil:

1.Thickness:0.17mm-1.5mm

2.Zinc coated:40g-275g/2

3.Standard:dx51d+z,sgcc

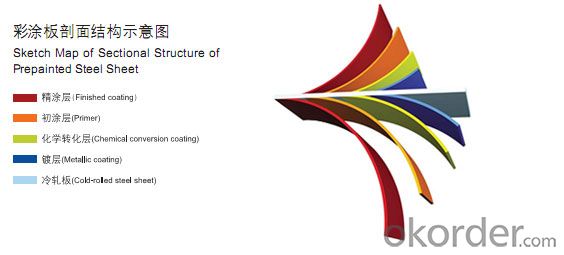

We manufacture Galvanized Steel Coils,Pre-painted Galvanized Steel Coils , etc

Prepainted steel coil features:

1. Zinc coating :40-120g(as reauired)

2. thickness:0.17-1.2mm

3. width:914-1250mm(900mm,1215mm,1250mm,1000mm the most common)

4. coil id:508m610mm

5. coil weight: 3-12(as required)

6. surface treatment:RAL color

Galvanized steel coil features:

1. Zinc coating :40-275g( as required)

2. thickness:0.17-1.2mm

3. width:914-1250mm(900mm,1215mm,1250mm,1000mm the most common)

4. coil id:508m610mm

5. coil weight: 3-12(as required)

6. surface treatment: cremated, oiled, skin passed

7. Spangle: regular,small, zero

8.Application: With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect.

Product name | steel coil,galvanized steel,galvanized steel coil |

Material | DX51D, SGCC, SPCC, CGCC, DX51D |

Normal thickness | 0.17-1.2mm |

Normal width | 900mm,914mm, 1000mm, 1200mm, 1220mm, 1250mm |

Coil weight | 3-12ns |

Certificate | BV & SGS |

Original | Shandong,China |

Payment terms | L/C or T/T |

Delivery time | within 15 ~ 25 days after 30% prepayment |

- Q: What is the yield strength of a steel strip?

- The maximum stress or force that a steel strip can bear before it permanently deforms or yields is known as its yield strength. This factor is vital in assessing the strip's appropriateness for different uses and its ability to endure external forces without sustaining lasting damage. The yield strength of a steel strip may differ depending on the specific grade or type of steel employed. It is commonly expressed as a force per unit area, such as pounds per square inch (psi) or megapascals (MPa). The yield strength is determined through a standardized testing method called a tensile test, which involves subjecting the steel strip to increasing levels of stress until it undergoes permanent deformation. The stress value at which this deformation occurs identifies the yield strength. Importantly, the yield strength is just one of numerous mechanical properties employed to evaluate the performance and suitability of a steel strip for a particular use. Other factors, including ductility, toughness, and hardness, also play significant roles.

- Q: How are steel strips sawed or cut with a bandsaw?

- Steel strips can be sawed or cut with a bandsaw by securing the strip on a stable surface and feeding it through the bandsaw blade, which moves in a continuous loop. The bandsaw blade features sharp teeth that cut through the steel strip as it is guided by the operator. This method allows for precise and efficient cutting of steel strips to desired lengths or shapes.

- Q: How are steel strips inspected for quality?

- Quality assessment of steel strips involves a rigorous series of processes and tests. The initial step in the inspection consists of visual examination, where industry experts scrutinize the surface of the steel strips for any discernible imperfections like scratches, dents, or cracks. This visual inspection guarantees that the strips conform to the necessary appearance standards. Following the visual examination, a variety of physical tests are performed on the steel strips. One of the most frequently conducted tests is the hardness test, which gauges the steel's resistance to indentation. This test is crucial since it determines the strength and durability of the strips. Another significant test is the tensile strength test, which measures the maximum amount of stress a strip can endure before fracturing. This test aids in evaluating the quality and suitability of the steel strips for their intended applications. Additionally, dimensional measurements are performed to verify that the steel strips meet the specified thickness, width, and length. Accuracy in these measurements is vital as it ensures the strips can be utilized effectively in various manufacturing processes. Furthermore, the steel strips undergo various chemical analyses to assess their composition and ensure that they meet the required chemical specifications. These analyses include testing for elements like carbon, manganese, sulfur, and phosphorus, among others. Moreover, the steel strips are subjected to surface quality tests such as measuring coating thickness, conducting adhesion tests, and testing corrosion resistance. These tests assist in determining if the protective coatings or finishes applied to the strips meet the necessary quality standards. All of these inspections are carried out using advanced equipment and techniques, including non-destructive testing methods like ultrasonic testing and magnetic particle inspection. These methods enable the detection of internal defects or flaws that may not be visible to the naked eye. In conclusion, the quality inspection of steel strips involves visual examination, physical tests, dimensional measurements, chemical analyses, and surface quality tests. These comprehensive inspections allow manufacturers to ensure that the steel strips meet the required standards and are suitable for their intended applications.

- Q: How do steel strips perform in terms of dimensional stability?

- Steel strips are known for their excellent dimensional stability. Due to their inherent strength and rigidity, steel strips are less prone to warping or changing shape compared to other materials, ensuring consistent dimensions and reliable performance in various applications.

- Q: What are the common heat treatment processes for steel strips?

- The common heat treatment processes for steel strips include annealing, tempering, quenching, and case hardening.

- Q: Are steel strips suitable for making architectural staircases?

- Yes, steel strips are suitable for making architectural staircases. Steel is a strong and durable material that can provide the necessary support and stability required for staircases. Additionally, steel strips can be customized and manipulated to create a variety of designs and styles, making them a versatile choice for architectural staircases.

- Q: How do steel strips resist temperature changes?

- Steel strips resist temperature changes due to their high thermal conductivity and low coefficient of thermal expansion. These properties allow steel to quickly transfer and dissipate heat, preventing the material from expanding or contracting significantly in response to temperature fluctuations. This ability to maintain dimensional stability even under extreme temperature conditions makes steel strips a suitable choice for various industrial applications.

- Q: Can steel strips be used in the production of knives and blades?

- Yes, steel strips can be used in the production of knives and blades. Steel strips provide a strong and durable material that can be shaped and sharpened to create high-quality cutting tools.

- Q: What are the important considerations for storing steel strips?

- The important considerations for storing steel strips include proper environmental conditions, such as a dry and well-ventilated area to prevent rust or corrosion. It is also crucial to store them in a horizontal position to avoid warping or bending. Additionally, they should be stored away from any chemicals or substances that could damage the steel. Regular inspections and maintenance should be conducted to ensure their integrity and quality.

- Q: Can steel strips be used for making automotive components?

- Yes, steel strips can be used for making automotive components. Steel strips are commonly used in the automotive industry for various applications such as body panels, frames, brackets, and reinforcements due to their strength, durability, and ability to withstand high temperatures and impacts.

Send your message to us

Color coated steel coils white color,green color,red color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords