Self Adhesive Aluminum Strips for Color Coated Aluminum Roofing Coil Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Exterior: tunnels,column covers , renovations...

(2).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

The strength and durability of aluminium alloys vary widely, not only as a result of the components of the specific alloy, but also as a result of heat treatments and manufacturing processes. A lack of knowledge of these aspects has from time to time led to improperly designed structures and gained aluminium a bad reputation.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

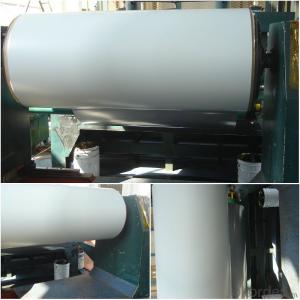

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: This question asks for guidance on selecting a dependable supplier for aluminum strips, implying the need for criteria to evaluate supplier reliability.

- <p>To choose a reliable supplier of aluminum strips, consider the following: Check their reputation and industry experience. Ensure they have certifications for quality management systems like ISO 9001. Look at their product quality, consistency, and adherence to industry standards. Evaluate their delivery times and reliability. Assess their customer service and after-sales support. Investigate their financial stability to avoid potential risks. Request references from current or past clients to gauge their performance. Finally, consider the supplier's ability to scale up production to meet your growing needs.</p>

- Q: What are the various kinds of flooring options available that utilize aluminum strips in their construction?

- <p>Aluminum strip flooring comes in several types, each with unique characteristics. One common type is aluminum strip laminate flooring, which combines aluminum strips with a laminate surface for durability and style. Another is aluminum strip interlocking flooring, known for its easy installation and resistance to moisture. There's also aluminum strip parquet flooring, which mimics the look of wood parquet but with the benefits of aluminum. Lastly, aluminum strip modular flooring is popular for its versatility and ability to be easily replaced or reconfigured. Each type offers different benefits, such as resistance to wear, moisture, and heat, making them suitable for various environments, from residential to commercial settings.</p>

- Q: Which is better, an aluminum belt excavator or a tire excavator?

- Crawler excavator horsepower (generally 220 horsepower or more), more than the mountain or the ground soil construction complex engineering, mining, large accident rescue; tire excavator is generally used in municipal engineering construction, small horsepower.

- Q: The user is inquiring if it's possible to use recycled paints or coatings to prevent rust and corrosion on aluminum strips.

- <p>Yes, you can use recycled paints or coatings to protect aluminum strips from rusting or corrosion. However, it's important to ensure that the recycled paints are compatible with aluminum and offer sufficient protection. Recycled paints should be free from contaminants that could compromise the protective layer. Additionally, the application process should be done correctly to ensure an even and effective coating. It's also recommended to test a small area first to verify the effectiveness of the recycled paint or coating before applying it to the entire surface of the aluminum strips.</p>

- Q: Can metal roofing materials be reused or recycled after they have been installed and used?

- <p>Yes, metal roofing materials can indeed be recycled after installation. Metal is one of the most recycled materials globally, and its recycling process is both efficient and environmentally friendly. When metal roofing reaches the end of its life, it can be collected, processed, and turned into new metal products, including new roofing materials. This recycling process helps conserve natural resources and reduces waste in landfills. The high recycled content of metal can also contribute to the sustainability and green credentials of construction projects.</p>

- Q: Is it possible to use aluminum strips for creating decorative accents or wall art?

- <p>Yes, aluminum strips can be used to create decorative accents or wall art. They are lightweight, durable, and come in various colors and finishes, making them a versatile material for crafting. You can bend, cut, and shape aluminum strips into different designs to suit your aesthetic preferences. Additionally, they are easy to install and can be used in combination with other materials to create unique and eye-catching wall art pieces.</p>

- Q: Does aluminum maintain its properties and resist damage from fire?

- <p>Aluminum strips are relatively fire-resistant, but not completely immune to damage. Aluminum has a high melting point of approximately 660掳C (1220掳F), which means it can withstand high temperatures without melting. However, it can still oxidize and corrode at elevated temperatures, leading to a loss of structural integrity over time. While it may not catch fire, it can still be affected by prolonged exposure to fire, and its performance can degrade depending on the specific conditions and the protective measures in place.</p>

- Q: Is it possible to recycle aluminum foil along with aluminum strips?

- <p>Yes, aluminum foil can be recycled with aluminum strips. Both are made of aluminum and can be processed together in recycling facilities. It's important to clean and separate them from other materials before recycling to ensure efficient processing. Recycling aluminum products helps conserve resources and reduces energy consumption compared to producing aluminum from raw materials.</p>

- Q: Is it possible to create a more energy-efficient roof using aluminum strips compared to other materials?

- <p>Yes, aluminum strips can be used to create a roof that is more energy-efficient than some other materials. Aluminum is a good conductor of heat, which can help in reflecting sunlight and reducing heat absorption, thus lowering cooling costs. Additionally, aluminum roofs can be designed with energy-efficient features such as solar reflectance and thermal emittance properties, which can further enhance their energy efficiency. However, it's important to consider the overall design, insulation, and installation quality to maximize energy efficiency.</p>

- Q: What are the specific types of coatings applied to aluminum strips to enhance their durability?

- <p>Yes, there are specific coatings used for aluminum strips to increase their durability. These include anodizing, which forms a protective oxide layer on the surface, and various chemical conversion coatings like chromate and phosphate treatments. Additionally, organic coatings such as polyester, epoxy, and acrylic can be applied for corrosion resistance and improved surface properties. Physical vapor deposition (PVD) and hot-dip galvanizing are also used for enhanced durability and protection against environmental factors.</p>

Send your message to us

Self Adhesive Aluminum Strips for Color Coated Aluminum Roofing Coil Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords