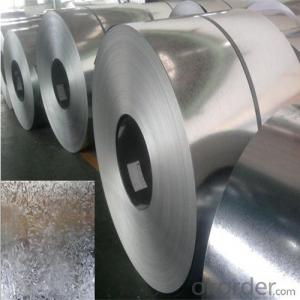

Cold Rolled Steel Sheet in Coil/High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

AISI,JIS,GB,BS,DIN,API,EN,ASTM

Technique:

Cold Rolled

Shape:

Round

Surface Treatment:

Oiled

Steel Grade:

Q195,Q215,Q215B,Q235B

Certification:

ISO,SGS,BV,IBR,CE

Thickness:

0.18mm-1.8mm

Width:

1000mm-1600mm

Length:

requirement

Outer Diameter:

according to weight

Net Weight:

10MT

Packaging:

Standard Export Packing

Cold Rolled Steel Coil:

| With the professional produce line, we can manufacture the best quality with competitive price as below: | |

| Thickness: | 0.18mm-1.20mm |

| Coil width: | 600mm-1250mm |

| Coil weight: | 3.0-5.0MT |

| Surface finish : | 60-275g/m2 zinc coating and the customers requirment! |

| Steel grades: | Q195-Q345,GR.A,GR.B, SPCC,SPHC,DX51D, ECT. |

| Standard: | JIS G3302, JIS G3313, ASTM A653, GB/T2518-88, GB11253-89,ASTM A1008- 2000,BS,ETC. |

| Packing: | wrapped by plastic film and waterproof paper, and then fastened on wooden pallet. Used in building material field,Pipe making, furniture making,others |

| MOQ: | 50tons |

| Delivery times : | 20 days after received T/T or L/C |

| Payment terms : | T/T or L/C ( or as your demand) |

| Supply ability : | 6,000 ton per month |

| County we ever exported: Indonesia, Georgia, Mozambique, Somalia, Myanmar, Argentina,India,Dubai, and Turkmenistan. we can supply you the products you need with most competitive price and high quality. special size and standard can be accepted! PRODUCT PICTURE:

WHY CHOOSE US: We are professional in products export. We have established longterm cooperation with forwarders and shipping company. We have more than twenty overseas houseware with timely aftersale service. We have complicate and professional quality control system, from material purchasing to products loading abroad. | |

- Q: How are steel coils used in the production of conveyor systems?

- Steel coils are used in the production of conveyor systems as they are formed into sturdy, durable belts that are capable of withstanding heavy loads and continuous operation. The coils are typically flattened and shaped into long lengths before being assembled into conveyor belts, ensuring optimal strength and flexibility for efficient material handling.

- Q: What are the dimensions of steel coils used in the storage tank industry?

- Steel coils used in the storage tank industry come in various dimensions, depending on the specific requirements of the tank being manufactured. Generally, these coils are available in different sizes and thicknesses. The width of the steel coils can range from approximately 600 millimeters to 2,400 millimeters. Similarly, the length can vary from a few meters to tens of meters. The thickness of the coils can also differ, typically ranging from 1.5 millimeters to 10 millimeters or more. Factors such as the size and capacity of the storage tank, the material being stored, and the structural requirements of the tank determine these dimensions. Consequently, the tank manufacturer or designer would determine the specific dimensions for a given storage tank project, following industry standards and project specifications.

- Q: can anyone help me to find any webpage about lists/types of stainless steel?

- Types of stainless steel There are over 150 grades of stainless steel, of which fifteen are most common. The AISI (American Iron and Steel Institute) defines the following grades among others: - 200 Series—austenitic iron-chromium-nickel-manganese alloys - 300 Series—austenitic iron-chromium-nickel alloys Type 301—highly ductile, for formed products. Also hardens rapidly during mechanical working. Type 303—free machining version of 304 via addition of sulfur Type 304—the most common; the classic 18/8 stainless steel Type 316—Alloy addition of molybdenum to prevent specific forms of corrosion - 400 Series—ferritic and martensitic alloys.

- Q: What are the different types of steel coil edge conditioning methods?

- There are several different types of steel coil edge conditioning methods, including slitting, cutting, shearing, and edge rolling. Slitting involves cutting the coil into narrower strips, while cutting involves separating the coil into smaller sections. Shearing is a process of cutting the edges of the coil to remove any irregularities or defects. Edge rolling is a method that involves rolling the edges of the coil to create a smoother and more uniform finish.

- Q: How are steel coils used in the petrochemical industry?

- Steel coils are commonly used in the petrochemical industry for various purposes such as manufacturing storage tanks, pipes, and equipment used in the refining and processing of petroleum and petrochemicals. The coils are often formed into specific shapes and sizes to meet the requirements of different applications, ensuring durability, strength, and resistance to corrosion and high temperatures in the harsh environments found in petrochemical plants.

- Q: hey therejust wondering about changing nylon strings to steel strings...i have an acoustic guitar and it has nylon strings, but i was thinking about switching to steel strings, as i think it sounds better.this might sound really stupid... but is that possible? i mean they call it a steel stringed GUITAR and nylon stringed GUITAR, so if i wanted to switch would i have to get a whole new guitar? please help, im reaaally confused!thanks

- I asked my guitar teach this and the thing with changing from nylon strings to steel strings is that the nylon tuning forks are accustomed to nylon and tend to slip. But, in say that you can do it, but, you would have to wait awhile for them to start sticking. If i have helped the Your welcome and Thanks! =]

- Q: I do a lot of scrapping and would like to be able to separate stainless steel from regular steel. The magnet test doesn't always work since stainless can be magnetic, but what are some ways that I can for sure tell the difference? Or even something like a sound that they make that may help me to tell the difference.

- Stainless steel uses chromium in its mixture to thwart the affects of corrosion. General steel, or carbon steel, is generally almost completely iron and is used for far greater applications than stainless steel. Stainless steel is used mostly in kitchen appliances, utensils, etc... The best thing I can come up with is to find a way to measure the chromium content of the steel you are looking at. If it's around 3% chromium, it's probably standard steel. If it's somewhere between 10-15% chromium it's probably stainless steel (or even 4% plus). I can't tell you a fast and quick way to test the steel because from my research, it appears there are as many grades and allows of steel as there are uses for steel! There is one test I've seen for home testing surgical steel which is a higher grade stainless steel, that is to put scotch tape on one section of material then soak it in water for a 24 hour period, then let it air dry for 24 hours. You remove the tape and lightly polish the exposed areas to see if there was any discoloration or pitting on the exposed area. This test is mainly for surgical steel jewelry, however stainless steel is supposed to resist rusting more than standard steel, hence it might work for other steel types as well. You may have to read some of the other links below to get some other ideas on how you can test steel to see if it is stainless.

- Q: How are steel coils processed and shaped into different products?

- Steel coils are processed and shaped into different products through a series of manufacturing processes. The first step in the process is called uncoiling, which involves unwinding the steel coil and straightening it. This is usually done by feeding the coil through a machine called a decoiler. Once the coil is uncoiled, it goes through a process called leveling. This is done to eliminate any unevenness or warping in the steel. The coil is passed through a set of rollers that apply pressure and flatten the steel to the desired thickness. This ensures that the steel is uniform and ready for further processing. After leveling, the steel is typically cut into smaller pieces or sheets. This is done using machines such as shears or slitters, which can cut the steel into different widths or lengths. The precise dimensions will depend on the requirements of the specific product being manufactured. Once the steel is cut, it can undergo additional shaping processes. One common method is called roll forming, where the steel is passed through a series of rollers that gradually shape it into the desired profile. This is often used to produce products such as roofing sheets, wall panels, or beams. Another common shaping process is called stamping. In stamping, the steel is pressed between a die and a punch to create complex shapes or patterns. This is commonly used in the automotive industry to produce components such as car body panels or engine parts. In addition to shaping, the steel may also undergo surface treatments or coatings to enhance its properties or improve its appearance. This can include processes such as galvanizing, where a layer of zinc is applied to protect the steel from corrosion, or painting to provide a decorative finish. Overall, the process of shaping steel coils into different products involves a combination of cutting, shaping, and surface treatments. These processes are carefully executed to ensure that the steel meets the required specifications and is ready for use in various industries.

- Q: What are the common methods of painting or coating steel coils?

- The common methods of painting or coating steel coils include coil coating, spray painting, electrostatic painting, and powder coating.

- Q: How is steel different than iron?How many different kinds of steel are there?What type is the strongest?Which type is the weakest?

- steel has carbon in it instead of just iron there are hundreds if not thousands of different kinds of steel for different applications strength depends on the definition. some have stronger tensile (pull) strength than others.

Send your message to us

Cold Rolled Steel Sheet in Coil/High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords