Cold drawn carbon fiber cut-off

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cold drawn carbon fiber cut-off

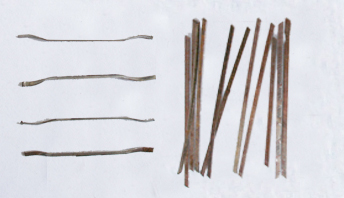

Concrete steel fiber: to cut off the thin wire method, cold-rolled strip steel cutting, milling or steel ingot quickly condensed into the legal aspect ratio (the ratio of fiber length to its diameter, when the fiber non-circular cross-section, using the conversion equivalent sectional diameter area of a circle) of 40 to 80 fibers.

Steel fiber is mainly used in the manufacture of steel fiber reinforced concrete, any method of production of steel fiber reinforced can play a role in concrete. The reinforcing effect of the fiber depends on the strength of the matrix (fm), the fiber aspect ratio (fiber length l and the diameter of the steel, the ratio d, the I / d), the volume ratio of the fiber (steel fibers of the percentage of the volume occupied by the concrete steel ), the adhesive strength between the fibers and the matrix (τ), and the fiber distribution in the matrix and orientation (η) of. When steel fiber reinforced concrete damage, mostly fibers are pulled out rather than pulled off, thus improving the bond strength between the fiber and the matrix is one of the main controlling factor in improving fiber reinforced effect.

Adding steel fiber concrete compressive strength, tensile strength, flexural strength, impact strength, toughness, toughness and other properties have been greatly improved.

Cold drawn carbon fiber cut-off

Cold drawn steel wire having a diameter of 0.4 ~ 1.0mm, and cut into a predetermined length in accordance with the short fibers.

Product Features:

Cold drawn steel wire made of steel fiber tensile strength of up to 1000 ~ 2000MPa, but its surface is smooth, the poor and the concrete or cement mortar matrix bond strength. In order to enhance the bond strength of steel fiber and the matrix, often can change the shape of steel fibers, namely, the production method of deformed steel fibers to be addressed. Its common methods are pressure ridge France, wave method, hook method.

Product specifications and models:

No. Type Length (mm) Diameter (mm) Tensile strength (MPa) shape

1 wire cutting type 20-60 0.4-1.0 ≥1100 corrugated

2 wire cut type 20-60 0.4-1.0 ≥1100 straight type

3 wire cut type 20-60 0.4-1.0 ≥1100 Bow

Application:

Carbon fiber cold Joan pattern type:

The basic shape and cut of the same type products are equivalent, but the tensile strength of monofilament has greatly improved, up 1100MPA more suitable for large area concrete crack key projects.

Cold-drawn steel fiber end hook:

This is the combined effect of the best products, with its high intensity (greater than 1100MPA), bending (more than ten times constantly) and riveted the best combination of the strongest end hook shape, and its products can be described as steel fiber of the family. "the boss. "

End hook steel fiber, steel fiber is a thin strip, the main features are: the middle section of steel fiber is linear, at both ends of the steel fibers have an upward tilt of the end of the hook, respectively. On the surface of both ends of the upturned end of the hook in the same horizontal plane, the ends were curled up under the surface of the end of the hook in the same horizontal plane. On the surface of both ends of the upturned end of the hook is higher than the upper surface of the middle section of the steel fibers, both ends of the lower surface of the upward tilt of the end of the hook is higher than the lower surface of the middle section of the steel fibers. Experiments show that the use of the utility model of steel fiber reinforced concrete, compressive strength, flexural strength early crack were increased by more than 27%, while the ultimate flexural strength increased by 67.7%, a 92.6% increase splitting tensile strength, resistance shear strength increased 101.6%.

- Q: What are the different types of steel forgings and castings?

- There are several different types of steel forgings and castings, including open-die forgings, closed-die forgings, and rolled-ring forgings. In terms of castings, there are sand castings, investment castings, and die castings. Each type has its own unique characteristics and benefits, making them suitable for different applications and industries.

- Q: How do steel products contribute to the telecommunications and networking industry?

- Steel products contribute to the telecommunications and networking industry by providing essential infrastructure and support. Steel is used in the construction of telecommunication towers, which are crucial for transmitting signals and ensuring reliable network coverage. Additionally, steel is used in the manufacturing of cable trays, cabinets, and enclosures that protect and organize the network equipment. Its durability and high strength properties make steel products reliable, ensuring the stability and longevity of telecommunication networks.

- Q: How is steel used in the manufacturing of transportation equipment?

- Steel is used in the manufacturing of transportation equipment due to its strength, durability, and versatility. It is commonly utilized in the construction of car frames, aircraft bodies, ship hulls, and railway tracks. Steel's properties make it suitable for handling heavy loads, providing structural integrity, and ensuring safety in various modes of transportation.

- Q: What are the different types of steel sheet and their uses?

- There are several types of steel sheets available, each with distinct properties and uses. Some common types include hot-rolled steel, cold-rolled steel, galvanized steel, and stainless steel. Hot-rolled steel sheets are often used in construction and manufacturing due to their strength and durability. Cold-rolled steel sheets, on the other hand, are smoother and have tighter tolerances, making them suitable for applications requiring precise dimensions. Galvanized steel sheets have a protective zinc coating, making them resistant to corrosion, and are commonly used in outdoor structures or for automotive parts. Stainless steel sheets are known for their resistance to corrosion and high temperature, making them ideal for applications in food processing, medical equipment, and chemical industries. Overall, the choice of steel sheet type depends on the specific requirements and intended use of the product.

- Q: What are the different types of steel beams and their applications?

- There are several different types of steel beams commonly used in construction and structural engineering. Some of the most common types include I-beams, H-beams, and S-beams. I-beams, also known as universal beams, have an "I" shape and are widely used for structural support in buildings, bridges, and other heavy construction projects. They are known for their high strength-to-weight ratio, making them ideal for carrying heavy loads over long spans. H-beams, or wide flange beams, have a wider flange and narrower web compared to I-beams. They are commonly used in residential and commercial construction, as well as in the manufacturing and automotive industries. H-beams are versatile and can withstand heavy loads and resist bending, making them suitable for applications that require extra strength. S-beams, also known as American Standard beams or S shapes, have a tapered flange and are commonly used in industrial and commercial construction projects. They are primarily used for support structures, such as columns and beams, and are known for their stability and durability. The choice of steel beam type depends on the specific requirements of the project, including load-bearing capacity, span length, and overall structural design. Consulting with a structural engineer is crucial to determine the appropriate type of steel beam for each application.

- Q: What are the different types of steel forgings and their applications in the defense industry?

- There are several different types of steel forgings used in the defense industry, each with its own unique properties and applications. Some common types include: 1. Carbon Steel Forgings: These are made from carbon steel and are known for their strength, durability, and resistance to wear and tear. They are commonly used in the manufacturing of artillery, tanks, and armored vehicles. 2. Alloy Steel Forgings: These are made by adding other elements such as chromium, nickel, or molybdenum to carbon steel, resulting in improved strength, toughness, and corrosion resistance. Alloy steel forgings find applications in the production of aircraft components, missile systems, and submarine parts. 3. Stainless Steel Forgings: These are highly corrosion-resistant and offer excellent strength and heat resistance. They are widely used in the defense industry for manufacturing firearms, ammunition, and small precision components. 4. Titanium Forgings: While not technically a type of steel forging, titanium forgings are commonly used in defense applications due to their lightweight yet high strength characteristics. They are used in the production of aircraft structures, missile components, and armor plating. Each type of steel forging has its own specific application in the defense industry, depending on the desired properties of strength, durability, corrosion resistance, or weight reduction. These forgings play a critical role in the manufacturing of various defense equipment, ensuring their reliability and performance in the most demanding conditions.

- Q: How is steel used in the construction of railway bridges and tracks?

- Steel is used extensively in the construction of railway bridges and tracks due to its high strength, durability, and resistance to corrosion. It is used to fabricate beams, columns, and girders that form the main structural elements of the bridge. Steel is also used to manufacture rails, sleepers, and fasteners for the tracks, ensuring a smooth and stable surface for trains to run on. Additionally, steel is used for reinforcing concrete in bridge piers and abutments, providing added strength and stability to the overall structure.

- Q: How are steel products used in the defense industry?

- Steel products are used in the defense industry for various purposes, including the construction of military vehicles, aircraft carriers, warships, and submarines. Steel is also used in the manufacturing of weapons, ammunition, and protective armor for soldiers and vehicles. Its high strength and durability make it a crucial material in ensuring the safety and effectiveness of defense equipment and structures.

- Q: How is steel used in the production of fire-resistant materials?

- Steel is often used as a reinforcing material in the production of fire-resistant materials. It is used to strengthen and support structures, such as fire doors, fireproof walls, and fire-resistant coatings. Steel's high melting point and durability make it an ideal choice to enhance the fire resistance of these materials, providing added protection against heat and flames.

- Q: How is steel tubing manufactured?

- Steel tubing is manufactured through a process called tube making, which involves various steps such as heating, welding, and shaping steel strips or plates into a cylindrical form. These strips are first heated and then passed through a series of rollers to form a continuous tube. The edges are then welded together, and the tube is further shaped and sized using additional rollers. Finally, the tube is cut to the desired length and undergoes various finishing processes to meet the required specifications and quality standards.

Send your message to us

Cold drawn carbon fiber cut-off

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords