Coated Alkali-resistant fiberglass mesh cloth (gram weight 110)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

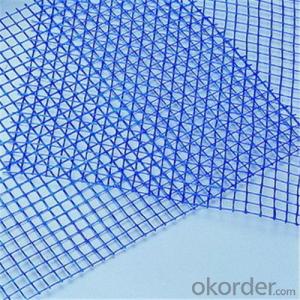

Coated Alkali-resistant fiberglass mesh cloth is

based on C-glass or E-glass woven cloth and

treated by alkali-resistance copolymer resin on

the surface.

The woven cloth is made of fiberglass yarn or

roving by means of leno or plain weave.

The diameter of elementary fiberglass varies

between 9 and 15 micron.

The resin used for the surface treatment ensures

the property of alkali-resistance and increases

the mechanical durability that is required by the

construction industry.

- Q: We live in an old, very poorly insulated house, and it's very drafty/cold during the winter. We've tried two-sided insulating tape that you put in the window sills, caulk strips that you put around the frame, etc. and none of it works. Is it worth the money to buy the plastic that you can put over the outside of your windows? The draft seems to be coming from where the window itself meets the sill, but also around the perimeter of the window (where the edging/molding is attached to the wall). I've read a few articles online about quot;how toquot; install plastic, but they all say that the plastic comes in kits and you need to attach it with the included double sided tape to your wooden window frame. our house is brick and there's not much of a frame outside. What little wood there is has been painted over many times, and I doubt tape would stick to it. Should I try to do it anyway? Is it worth the cost?

- You can caulk around the windows first. That should have been done at instalation. If you need to, you can use 100% silicone to adhear the plastic to plastic and it is easily removed in the spring. Do a test section and let it cure for 48 hours and see how it holds and removes. I never did it but I do alot of caulking. If you dont seal the draft, no matter what you do, it will eventually blow off.

- Q: Someone said to me 1: 2 of the cement mortar, 100KG water, 2 sea head to cook the Curcuma Cui Feng who Nanking 00 cement. Is that right? Is there any other material such as gravel? More

- 1: 2 cement mortar is made with 1 unit weight of cement and 2 units of weight sand, actually ignoring the composition of water, usually around 0.. that should be 1 (cement): 2 (sand): 0.6 (water) The By the cement, fine aggregate and water, as well as the need to join the lime, active admixture or admixture in the field of the mortar, divided into cement mortar and cement mortar. Generally speaking, 1: 3 cement mortar is used in 1 unit weight of cement and 3 units of weight sand, in fact, ignore the water composition, generally about 0.6 ratio, which should be 1: 3: 0.. the density of cement mortar 2000Kg / m3.

- Q: Can steel props be used in the construction of schools?

- Yes, steel props can be used in the construction of schools. Steel props are commonly used to support temporary structures during construction, including scaffolding, formwork, and falsework. They provide stability and strength to ensure the safety of the construction site and workers. In the case of school construction, steel props can be used to support various elements such as beams, columns, and floors, ensuring the structural integrity of the building.

- Q: Whether the size of the composite floor 812 * 150 is standard

- Strengthen the floor This basically does not have a uniform size manufacturers in the production of the time according to their own circumstances and the country for the size of the general size of the provisions of many of the main focus on 1. Long 800 above the width of 120 or more 2.1200 above 160

- Q: Geotextile, 150g how much money per square meter

- 1.2 to 1.5. See quality requirements. Huazhi geotextile material manufacturers

- Q: film is for decorative reason, not for some protection

- The instructions are in the kit, but you clean the window first using a dust free cloth, put a mixture of baby shampoo and water in a spray bottle, cut the sheet to fit the window pane leaving about 1/2 in over hang on all sides. Spray the window and the back of the sheet with the solution and starting in the middle burnish the film down getting out all the air bubbles. Trim the sheet with a sharp razor blade and wipe up the excess water of the sill. Let it dry before trying to clean it and that's about it. Good luck

- Q: What are the environmental benefits of using geomembranes?

- Geomembranes offer several environmental benefits. Firstly, they act as a barrier, preventing contamination of soil and groundwater by hazardous substances, such as chemicals or waste materials. This helps protect the environment and ensure the safety of nearby ecosystems and water sources. Additionally, geomembranes can be used in landfills to minimize the release of harmful gases, such as methane, into the atmosphere, reducing the contribution to greenhouse gas emissions and climate change. Moreover, they can be used in various containment applications, such as wastewater treatment ponds or mining facilities, to prevent the leakage or seepage of pollutants, thus safeguarding surrounding environments. Overall, geomembranes play a crucial role in preserving and protecting the environment by preventing contamination and minimizing negative impacts on ecosystems and natural resources.

- Q: How much is a normal plastic floor

- PVC floor, also known as plastic flooring, different regions are also different names. Prices generally in 28-500 yuan / square meter. According to the local situation to locate.

- Q: How do you ensure proper alignment when connecting steel tube couplers in scaffolding?

- For safety and stability, it is crucial to have proper alignment when connecting steel tube couplers in scaffolding. To achieve this, here are some important steps to follow: 1. Before connecting the steel tube couplers, carefully inspect them to ensure they are in good condition and free from any damage or defects. This will help guarantee a proper fit and alignment. 2. Choose the appropriate type of coupler for the specific connection you are making. There are different types available, such as swivel couplers, sleeve couplers, or putlog couplers, each serving a different purpose. 3. Measure and mark the exact positions where the couplers will be connected on the steel tubes. This will ensure accurate alignment and prevent any errors during the connection process. 4. Clean the surfaces of both the steel tubes and the couplers before connecting them. Removing any dirt, rust, or debris will improve grip and ensure proper alignment. 5. Carefully align the couplers with the marked positions on the steel tubes, making sure to follow the manufacturer's instructions regarding orientation. This will result in a secure and stable connection. 6. Use the appropriate tools to securely tighten the bolts or fasteners once the couplers are aligned. It is important to follow the recommended torque specifications provided by the manufacturer to avoid misalignment and maintain stability. 7. Double-check the alignment after connecting the couplers to ensure they are properly seated and aligned. Look for any signs of misalignment, such as gaps or unevenness, and make necessary adjustments if needed. 8. Regularly inspect the scaffolding structure, including the steel tube couplers, to ensure proper alignment is maintained. Any signs of misalignment, movement, or deterioration should be addressed immediately to prevent accidents or structural failures. By following these steps, you can ensure proper alignment when connecting steel tube couplers in scaffolding, providing a safe and reliable working platform for workers at height.

- Q: What is the weight of steel formwork panels?

- The weight of steel formwork panels may differ based on their size, thickness, and design. Typically, the weight of steel formwork panels can range between 20 and 30 kilograms per square meter. Nevertheless, it should be noted that this weight can be altered according to the specific demands and customization of a project. It is also recommended to seek guidance from manufacturers or suppliers to acquire precise and current details regarding the weight of steel formwork panels for a specific application.

Send your message to us

Coated Alkali-resistant fiberglass mesh cloth (gram weight 110)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches