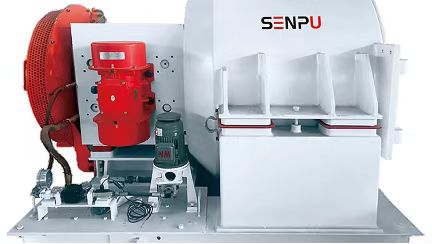

Coal washing and beneficiation equipment HVC Horizontal Vibrating Discharge Centrifuge

- Supplier:

TANGSHAN ZHONGQING MACHINERY CO.,LTD

TANGSHAN ZHONGQING MACHINERY CO.,LTD

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 60 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The LWZ screen-bowl centrifuge is suitable for the dewatering and recovery of -0.5mm coal fines. It offers a series of advantages, including large capacity, low product moisture, simple drive system, long service life of wearing parts and use of intelligent control system. It has been awarded 4 national patents and the honors of being a research-derived achievement of Hebei Province and National Key New Product, and is the winners of 5 prizes bestowed by China Building Material Group and Tangshan City for its scientific and technological progress, etc. Now, 6 sizes ranging from LWZ800×1600 to LWZ1600×2400 are available.

This kind of centrifuge is suitable for the dewatering and recovery of fine cleaned coal or small middlings. It offers a series of advantages, including high capacity, low product moisture, low noise level, stable vibrating amplitude, low fault rate and easy replacement of worn-out parts. It can be used as a substitute for an imported counterpart. The centrifuge has been granted 2 national patents. Now, 7 sizes ranging from HVC1000 to HVC1650 are available.

- Q: What are the core components of an ultrasonic shaker?

- The ultrasonic power supply box also called stepless frequency ultrasonic generator, the generator frequency is generally between 15~80KHZ, and can be accurate in the fluctuation range of 0.1KHZ free adjustment, more powerful is stepless frequency ultrasonic generator with frequency automatic follow function, can be automatically adjusted, which can make the ultrasonic power supply box to achieve the most suitable ultrasonic vibration sieve extension working state

- Q: OK, where can I get the shaker dust collector?

- The device consists of dust catcher, fan, pLc automatic pulse blowing system, hanger, inspection door, sealing soft curtain and so on. The use of vibrating screen dust collector can avoid the dust flying everywhere and pollute the environment, and contribute a lot to the protection of the earth environment. With the increase of the surface of the filter bag dust, knife resistance value reaches a predetermined value, the pressure sensor to the electronic control box indicating signal, by pLc automatic control system for automatic pulse jet bag was blowing, attached to the bag on the dust shake off, after unloading ash pipe directly to the sealing belt. That is to keep the filter bag good filter performance, and no two dust.

- Q: What is the structure of the LZS cold shale shaker?

- The screen frame side plate is made of a whole piece of high quality steel plate, and the connection between the side plate, the reinforcing rib and the crossbeam and the vibrator bottom frame is connected with the self-locking nut or the ring groove rivet by the high strength bolt.

- Q: Selection is good or sub ballast drum sieve shaker.

- Because the material rolls and rolls in the drum, the material stuck in the sieve can be ejected to prevent the screen from clogging. The principle and structure of roller screen sand machine, drum screen and roller screen are almost the same.

- Q: What is the feed vibrating screen used for?

- 1. Screen the impurities in feed material.2 grade screening of raw materials after grinding.3. Clean the impurities before granulation.4, grading screening, granulation products.

- Q: Mounting angle of vibrating screen

- Different types of vibrating screen installation angle is different, such as vibration screen installation angle of more than 30 degrees, general purpose vibration sieve angle of 0-15 degrees, while the sieve used for dewatering is the end of the upward tilt

- Q: What is the working principle of a vertical vibrating screen? What about the structure?

- The two motor shaft relative to the screen surface has a dip in the excitation force and material from the joint effect of gravity, the material in the sieve surface toss leap forward in a straight line, so as to achieve on the materials selection and classification purposes.

- Q: Why are the vibrating motors installed in different locations?

- In fact, the vibration of the motor production, clearance between shaft and bearing and the general motors is not the same, must be close coordination between the motor shaft and the bearing clearance, and axial vibration motor and bearing is sliding fit between 0.01--0.015mm gap in maintenance will certainly feel the shaft will produce about string. In fact, the gap coordination has its important role.The vibration motor is by itself to generate high-frequency vibration, vibration, so in the working time, the motor itself will have very high temperature, it is due to the clearance of the existence of expansion in the temperature rise after the vibration of the motor shaft, the shaft and the bearing is expanded to close cooperate to achieve the normal working state, if the gap is not 0.01--0.0115mm, so the vibration of the motor in the working temperature reaches a certain temperature will cause a series of problems, even stopped or burned vibration motor. Therefore, we should pay attention to this problem in the maintenance of vibration motors.

- Q: What is the working principle of high frequency vibrating screen?

- Through the belt shaft driving two unconnected vibrator synchronous reverse operation, force superposition centrifugal force two eccentric quality generated along the direction of vibration, reverse centrifugal offset, thereby forming along the direction of vibration induced vibration sieve box single, make reciprocating rectilinear motion.

- Q: How can eccentric wheels be justified only if a vibrating screen with one eccentric wheel is installed?

- The eccentric wheel frame is often crack, you may consider a symmetrical arrangement of two, the total mass is half of the original quality, also should consider the change often split components of materials, should be soft and not easy to crack the material, the round to crack place.

Send your message to us

Coal washing and beneficiation equipment HVC Horizontal Vibrating Discharge Centrifuge

- Supplier:

TANGSHAN ZHONGQING MACHINERY CO.,LTD

TANGSHAN ZHONGQING MACHINERY CO.,LTD

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 60 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products