Four Side Moulder For Wood Working Machinery

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Four Side Moulder for woodworking machinery

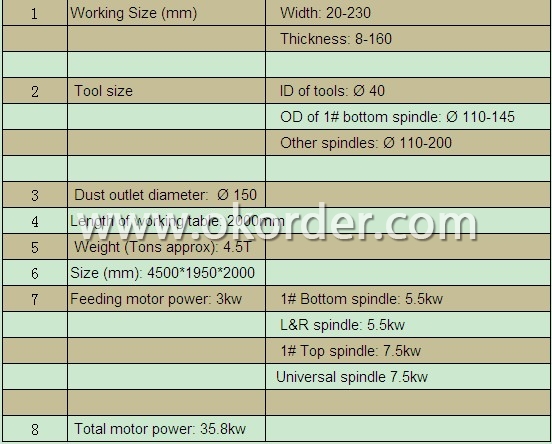

1. All machines base are processed by big CNC machine to assure the high precision. The width of working table is 250mm and working thickness is 120mm. The wider machine base is good to keep good stability and working precision. All the electric components are adopted international brands to assure stable and excellence performance.

2. It is suitable to process flooring, wood strip, windows, cabinet etc products.

Advantage for Four Side Moulder for woodworking machinery

1. Adopted upturning short pieces device, the min. processing length is 200mm

2. Groups of bottom rollers to assure feeding smoothly. The first bottom feeding rollers is moved up- down with the working table

3. High speed spindle is made by alloy steel and assembled SKF bearings inside

4. Centralized lubrication system. Slide parts and working table are lubricated by two manual oil pumps separately

Options of Four Side Moulder for woodworking machinery

1. Y-delta start for each spindle

2. Inverter for feeding, speed is 6-30m/min

3. Electric oil pump to lubricate

4. CE norm

5. Min processing length with 180mm

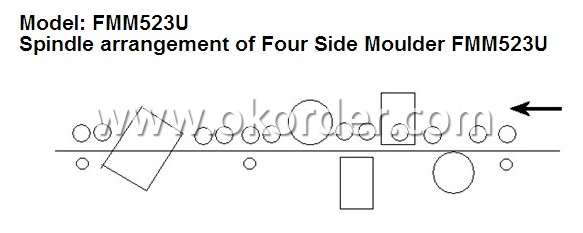

Specifications of Four Side Moulder for woodworking machinery

Packing of Four Side Moulder for woodworking machinery

- Q: Please hand woodworking planer, the wooden part is what species?

- The commonly used woodworking planer with woodSouth oak wood is dark red, more commonly used materials, high-grade general cargo container frame. Relatively heavy.The Japanese side oak, orange red, is the ideal material.

- Q: A woodworking plane planer installation angle is?

- In the cutter spindle mounted at 30 degrees angle, blade angle in 20 planes to 45 degrees, see materials and planing speed to increase or decrease by cutting edge strengthening processing tool, its service life can be increased by 70%. The better wear resistance of cutting tools.

- Q: I have a woodworking planer, the hardness is not enough, how can we strengthen the hardness of it

- Strictly speaking, heat treatment is necessary, but it is of little significance to strengthen hardness if it is only for bad use

- Q: How to wear woodworking planer grinding sharper?

- First rough grinding, after grinding in strong light place, until you see a small blade on the edge of the knife, and then fine grinding grinding.

- Q: Who knows the installation method of woodworking planer?

- And a small piece of wood stuck!My father used to be a carpenter. I saw moreSmall pieces of wood should be along with the size bladeSmall wood chip to Guanghua, how can the network even sold together with wood chips?Pressure mounted on the iron screw, and cutter together edge alignment, lies in, pressure in iron, into the plane, again on a wooden wedge.

- Q: A woodworking plane how to adjust the use of methods and skills?

- Recognize the exterior and the interior, distinguish the grain from the wood, and make no effort: the plane of the wood should be distinguished from the wood before planing, and then the direction of planing shall be decided so as to avoid the difference of the battle. Generally planing surface, it should be material to the root direction of the plane, planing, when inside, from the root to the material tip direction plane.

- Q: Woodworking planer hard alloy cutter to welding

- For welding strength, good wettability and fluidity shall be guaranteed, and foaming shall be eliminated so as to prevent welding from occurring;

- Q: What tools are needed for interior door mounting carpenters?

- A woodworking implement, as of wood. Generally have a sharp edge, and must pay attention to safety when using. Need regular grinding, especially knives, chisels, should be sharpened, in order to use the advantages of labor saving, and ensure the quality, the so-called "modaobuwukanchaigong" is the truth.

- Q: How many degrees of ability of woodworking machinery cutter grinding durable

- And you processed wood hardness, generally at 45 degrees, the harder the angle, the more sharp, easy to corner. If it is an alloy knife, it must be greater than 45 degrees because the alloy knife is not shock resistant.

- Q: What brand of carbide woodworking planer good quality?

- Cemented carbide is a kind of alloy material made by powder metallurgy process of hard metal and bonding metal of refractory metal.

1. Manufacturer Overview

| Location | Foshan,China |

| Year Established | 2007 |

| Annual Output Value | Above US$230 Million |

| Main Markets | Southeast Asia Countries; South America Countries; East European Countries |

| Company Certifications | ISO9001; CQC; CE |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Rongqi; Beijiao; Huangpu; Shenzhen |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 200- 300 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 40,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average; Low |

Send your message to us

Four Side Moulder For Wood Working Machinery

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches