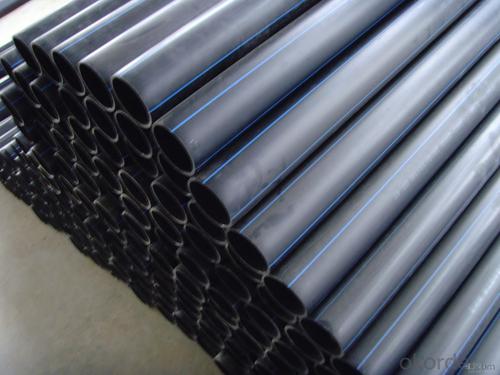

Plastic Tubes - CNBM HDPE Pipe PVC Pipe and Fittings ISO4277

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 3000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

ISO 4427 hdpe pipe

1.Manufacture

2.Application:water supply

3.Diameter:20-1000mm

Advantages:

1.Nontoxic:

PE pipe material nontoxic, tasteless,it belongs to green building materials, never scaling,

which can effectively improve the water quality.

2.Corrosion resistance:

High resistance to attack from various types of chemicals. No electrochemical corrosion.

3.No Leakage:

PE pipe is connected in the ways of butt fusion, socket fusion and electrofusion and the

strength of joint point is higher than tube itself .

4.higher flow capacity:

The Smooth inner wall is easy for pipeline transportation .Under the same condition

delivery capacity can be increased by 30%.

5.Convenient for construction and installation:

PE pipe could be installed in a variety of trenchless ways, so it is very convenient for

construction and installation.

6.Lower system and maintenance costs:

PE pipe is not only convenient to transport and install, but also reduce the worker’s

labor intensity and improve work efficiency.

7.Longevity:

50 years under pressure use.

8. Recycled and Environment-friendly

- Q: Are plastic tubes suitable for medical diagnostics?

- Yes, plastic tubes are suitable for medical diagnostics. They are commonly used in various diagnostic procedures, such as blood collection, urine testing, and sample storage. Plastic tubes are lightweight, cost-effective, and have excellent chemical resistance, making them suitable for handling and transporting biological samples in a safe and efficient manner. Additionally, they are available in different sizes and configurations to accommodate specific diagnostic needs.

- Q: Can plastic tubes be used for water filtration systems?

- Yes, plastic tubes can be used for water filtration systems. Plastic tubes are commonly used in water filtration systems as they are durable, flexible, and resistant to corrosion. They can efficiently transport water through different stages of filtration, allowing for effective removal of impurities and contaminants.

- Q: Please help me!!! This is for my science class and i am so confused xS

- A magnet is not attracted to copper, so you might expect that it would not have any effect. But there is another property of magnets to keep in mind: a moving magnet produces an electric field. So, as the cow magnet moves through the copper tube, it creates an electric field that sets up small electric currents in the copper tube. These moving eddy currents in the copper have their own electric fields that work against the field of the magnet. These interacting fields are what slows down the cow magnet. The plastic tube is not affected by the moving magnetic field of the cow magnet, because plastic is not a conductor so no electric field is created in the plastic tube. We are most familiar with a moving magnet creating an electric current in a wire, the way a spinning magnet in an electric generator creates a flow of electricity, but a moving magnet will create an electric current in any conductor. It doesn't have to be a wire, and it doesn't have to be ferromagnetic. Hope this helps a bit.

- Q: What are the advantages of using plastic tubes in the cosmetics industry?

- There are several advantages of using plastic tubes in the cosmetics industry. Firstly, plastic tubes are lightweight and portable, making them convenient for travel or on-the-go use. Secondly, plastic tubes are cost-effective compared to other packaging materials, allowing for more affordable pricing of cosmetic products. Additionally, plastic tubes are flexible and can be easily squeezed, enabling precise and controlled dispensing of the product. Moreover, plastic tubes provide excellent barrier properties, protecting the product from air, moisture, and contamination, which helps to extend the shelf life of cosmetics. Lastly, plastic tubes can be easily customized with different shapes, sizes, and printing options, allowing for branding and marketing opportunities for cosmetic companies.

- Q: Where des this charge come from? Why don't we see a charge on the fur or wool?

- while something is rubbed with something else what comes into play is Frictional electrical energy . there is something called the paintings function it fairly is the minimum potential required via the electrons on the exterior to circulate away it . So if Fur and rubber are rubbed in accordance to the ques rubber rod will become negatively charged hence fur might desire to be dropping electrons hence , btw utilising molecules doesnt appear as if a stable theory to me so , in accordance to me C is the final answer .

- Q: Two identical bar magnets are dropped at the same time from the same height down tubes of the same length. Magnet A is dropped down an aluminum tube while magnet B is dropped down a plastic (non-conducting) tube. Which magnet reaches the bottom of the tubes first? Magnet A will not fall through a conducting tube. Both arrive at the same time. Magnet A. Magnet B. The answer depends on the permeability of the plastic in the plastic tube.

- No madam same twins such as you could no longer have comparable face and top so whats the component u opt to grow to be same twins do no longer hesitate bypass forward which contain your analyze in genetics i informed u do no longer produce a clone thats very final answer out of your bestest pal so what u call.

- Q: i was thinking sterilization cause due to being a surgical instrument, but can we sterilse plastic in autoclave or UV lights? confusing question.......

- Most plastic stuff comes already sterile from the manufacturer. There is the option of gas sterilization, if the tubing won't survive an autoclave. Most surgical instruments are metal and ARE re-sterilized, at least in the OR's where I work. We don't reuse tubing.

- Q: can you use rubber tubing to make moonshine?

- It's fine to use rubber. That other guy doesn't know what he's talking about.

- Q: Ok im in 6th grade and we have to make a roller coaster with 3 hills and a loop..ANYONE KNOW WHERE I CAN GET CLEAR-FLEXIBLE TUBING???(Please dont say im too yooung i have permission to be on here) Please help urgent!Much appreciated

- any pet store with a fish section will typically have 3/8in clear plastic tubing... look in the bubble wall and air pump section for fish tanks.

- Q: Are plastic tubes suitable for chemical storage?

- Plastic tubes can be suitable for chemical storage depending on the type of chemical being stored and the specific properties of the plastic material. It is essential to consider factors such as chemical compatibility, temperature resistance, and potential reactions between the chemical and the plastic. Additionally, proper labeling, sealing, and storage conditions should be followed to ensure safety and prevent any leakage or degradation of the plastic tubes.

Send your message to us

Plastic Tubes - CNBM HDPE Pipe PVC Pipe and Fittings ISO4277

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 3000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords