CMAX - WHEEL LOADER SERIE - 457 MODEL,All switches and auxiliary controls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

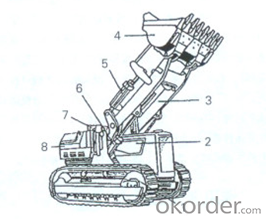

The all-new JCB 457 gives you, epic style, visibility, power, speed, strength, efficiency and quality. Featuring a powerful new MTU diesel engine that meets Tier 4 final emissions without the need for a costly and in-efficient DPF. New JCB CommandPlus cab provides the ultimate in operator comfort and productivity. Unrivalled visibility, command driving position and seat mounted controls keep you in total command. Innovative design provides easier ground level service access with a one piece automatic opening bonnet. Tailored service packages and the best dealer backup complete the picture. A machine designed and built to be everything you’re looking for in a wheeled loader.

• You’ll immediately notice the redesigned ROPS structure on the new JCB 457; this has allowed the A pillars to be moved to the same width as the rear of the cab, providing a larger interior with a panoramic front windscreen.

• Controlling the loader is now easier than ever – all of the controls are seat-mounted, even going as far as to move with the seat suspension. All switches and auxiliary controls are now located on the right-hand A-pillar for easier access.

• There are two full colour LCD screens to navigate your 457’s operating menus, with one doubling as a monitor for the rear view camera. Using this simple, dedicated menu interface is easily done with an intuitive optional rotary controller.

• Select the control system that’s best for your wheel loader operators; we offer single lever joystick or multi-lever configurations, both fully electro-hydraulic. The noise level in the cab is now an incredibly low 68 dB(a).

• An all-new air venting system boasts nine demisting vents and six operator vents to maintain visibility and operator comfort at all times. It also operates at a reduced noise level.

• After extensive research into operator ergonomics, we’ve devised the Command Driving Position specifically for the 457 wheeled loading shovel, which boasts the very optimal control layout for a multitude of different driver shapes and sizes.

• The new JCB 457 wheel loader’s MTU engine offers you plenty of low-end torque and maintains it over a wide power band. By using lightweight materials in the construction of the machine, you can also expect an excellent power-to-weight ratio.

• To save on fuel, the engine idle shutdown feature can safely apply the brakes and turn your machine off after a programmable amount of time.

• A hydraulic cooling fan automatically reacts to ambient temperature and adjusts your wheeled loading shovel’s fan speed to optimise cooling and reduce fuel consumption. This also lowers noise on your site.

• Opt for the torque lock up 5-speed transmission and you’ll get 100% efficiency in second to fifth gears, as well as closer gear ratios to keep engine speeds down. The end result is improved fuel economy.

• Wheel speed braking means the brakes on the new JCB 457 front loader rotate at the same speed as the wheels for heat and drag reduction, as well as improved fuel economy.

• JCB’s innovative variable displacement pumps feed a load-sensing valve block which only consumes power on demand. Unloaded spool valves in the valve block allow the arms to lower under gravitational – not hydraulic – force; this reduces fuel consumption still further.

If you plan to use your new JCB 457 wheel loader for quarry work, choose the dedicated quarry safety pack, which includes blue flashing reverse lights, a green operator presence beacon, a rear object detection system, and hi-viz exterior chevrons.

• Access steps are inclined and equally spaced, complemented by well positioned grab handles for three points of contact at all times.

• On the new JCB 457, you’ll find the rear-view mirrors mounted in front of the A-pillars for improved visibility. Interior mirrors, heated exterior mirrors and bonnet mirrors combine to offer excellent views to every corner of your wheeled loading shovel.

• The new front fender flaps have been carefully designed and honed to keep forward spray to a minimum. This increases safety and decreases debris build-up on your wheeled loading shovel.

• The new 457’s cab is isolator-mounted, compliant with ROPS/FOPS standards, and positively pressurised against dust. You can choose from fresh air, carbon and P3 – HEPA recirculation filters as well.

• Door hinges are now mounted on the B-pillar; this simple change has created much better access via a larger and wider door aperture. It also means you can access the rear roof of your wheel loader more safely.

• It’s easy to get to the engine on a new JCB 457 with a large automatic opening single-piece bonnet. Accessing the diesel and DEF tanks is similarly straightforward via the lockable grille at the rear of the machine.

• This wheel loader’s braking system has a virtually maintenance-free lifespan courtesy of full dual circuit hydraulics with multiple oil-immersed discs.

• Most Tier 4 final engines use a costly Diesel Particulate Filter (DPF) that can require replacement at the expense of both money and time. The MTU engine in the new JCB 457 is DPF-free, thus reducing your servicing and running costs.

• The standard cooling package is a large single-faced unit so you can be assured of quick, easy and safe cleaning.

• You can check brake, steering and hydraulic system pressures easily courtesy of group test ports. The main fuse board and relays have been repositioned next to the door for easy access.

• By using exclusively premium components (MTU engine, ZF transmissions and axles, Rexroth pumps and Parker valve blocks) on the new JCB 457 wheel loader, we’ve built in long service life as standard.

• The MTU 6R1000 470in3 engine fitted to the new JCB 457 produces 193kW (258hp) of power and 848 lbft of torque (6% more than our outgoing model). What’s more, it produces all of this at low revs for incredibly responsive operation.

• There’s no need to worry about wasting time and money replacing a diesel particulate filter (DPF) on your wheel loader; its MTU engine requires only exhaust gas recirculation (EGR) and system selective catalytic reduction (DOC). This also improves fuel economy.

• Powerful twin variable displacement piston pump hydraulics can circulate a massive 70 gal/min for fast cycle times and excellent multifunctioning capability. With maximum breakout forces of 38,667lbf, this wheel loader has the power to carry out extremely arduous loading jobs.

• Specify your perfect loader arm: Z-bar linkage (ZX) for high breakout applications or high torque (HT) for parallel lifting and multi attachment work. High lift and super high lift options equip your 457 for applications involving high loading heights.

• This wheeled loading shovel’s innovative electronic management system can perform progressive clutch cut-off for efficient, productive loader control. This feature controls tractive effort via the transmission, diverting maximum power to the loader hydraulics and reducing service brake wear and fuel consumption.

• You can choose from three axle options on the new JCB 457 wheel loader: open differentials for hard standing; limited slip differentials for soft, muddy terrain; or open differentials with an automatic locking front diff for varied conditions.

• All JCB wheel loaders including the new 457 benefit from finite element analysis and rig testing of up to 1 million cycles to ensure superior strength and durability. Cold cell testing guarantees starting performance down to -4°F.

• High tolerances and accurate location of pins and bushes are assured with JCB’s precision machining techniques. State-of-the-art manufacturing processes like robot machining, precision paint technology and innovative assembly techniques help to achieve the very highest levels of build quality.

• The new MTU engine has all the grunt you need for day-to-day loader operation, together with a rugged construction that can cope with sudden, hard load changes when switching between tasks.

• This wheel loading shovel’s articulation joint has a heavy-duty box section, a heavy-duty centre pin and oversized bush, as well as twin taper roller bearings on the bottom box joints. This setup can easily tolerate both vertical and horizontal loadings.

• A solid cast rear counterweight protects your JCB 457 wheel loader’s back end – including the rear lights and cooling pack – from damage. Hoses are neatly routed and clamped through the articulation joint, well away from any pinch points.

• You can specify your wheeled loading shovel for heavy-duty applications like waste or corrosive material handling.

- Q: Ok so I've been using this for more than 2 months then When I exited a game,Uploaded some music on my PSP.I opened My Prometheus,So everything was fine,Until when I selected a game It would say quot;Loading WWE Smackdown vs Raw 2011Then the whole screen goes black,then returns to main menu of my PSP.This also happens with all my games.PLEASE HELP!!!

- press select button. 1)change UMD ISO MODE - M33 DRIVER 2)change CPU CLOCK XMB - 333/166 3)change CPU CLOCK GAME - Default or use open idea iso loader

- Q: I have a Garmin streetpiolet c530 and when i turn it on, its stuck on loader loading. I tryed resetting it, plugging it into the car, and computer, but nothing is working... please help! im going on a road trip soon and need my GPS

- lol piolet, loader loading, you should take a watter bottle and other survival items with you too, knowing you you're gonna need them

- Q: preferably used and in fair to good condition

- sorry dan i don't know

- Q: vs all other actions? Or is it just for fun nowadays?

- 1st advantage is you get to start hunting sooner. 2nd advantage is if you hit it with a .50 cal ball it ain't gettin' up 3rd advantage is if you get a kill with a muzzle loader you've really done something. 4th advantage is they are a blast to shoot.

- Q: Ok so i have never had a mag loader before or mag speed loaders. but i have a burning desire to get one. i don't know anything about them. so a couple questions. will they fit all my guns or will they only fit one? are the expensive ones any better then the cheap ones? what is a good budget speed loader that will work on my sig sp2022 9mm mags?-Thanks

- Speed loaders are made to fit specific magazines, not guns. Some magazines will work in more than one gun, so your speed loader naturally can be used for loading the magazines for those guns. Speed loaders really do not speed up the loading process. Their main purpose is to make it easier on your fingers and thumb because if you load a magazine several times or have several magazines to load it can take a toll on your hands.

- Q: It is called a bull dog 725 mini wheel loader articulated 4 by 4 bucket orops gas engine

- hehehe... Where did you lose it at?.... Seriously... how about some more information here... is this a tractor? skid steer loader (ie 'bobcat'), a model, a toy, etc...and did you spell the brand name correctly?

- Q: they find it hard to believe clothes cant get clean with small amounts of water and they dont understand how it can do that, how it works??i mean theyre so popular in the UK europe so why do people think its weird??

- They do work properly if used as instructed in the user manual. I have used both top loaders and front loaders and I find front loaders get the clothes cleaner and are much more gentle on them apart from being more economic in water and electricity to run. If things are not coming clean it is because they are on the wrong wash or the incorrect powder/dosage is used.

- Q: Whirlpool Duet Ten Cycle Front Loader..Good Machine?Me and my mom are thinking about purchasing this machine.Do you / Have you owned this machine?Can you tell me some pros and or cons about it, how well it washes, ect.?And if you did have it why did you decide to get rid of it?Thank you for your help it was greatly appreciated. =)

- yes i own one and it has done a really good job, have the duet full size unit, they now make the sport version, but i like the full size unit . I do factory whirlpool repair and have done less repair on the full size unit hope you like it

- Q: version4.1 model mc jailbreak greenpois0n rc5 loader is not opening

- On the iPod touch 1g and 2g with iOS 4.1 and 4.2.1, there have been many times where Greenpois0n has failed to jailbreak and resulted in an iBrick (the famous expensive paperweight). And, when it actually does work, Loader refuses to open or download Cydia. When this happens, the device becomes extremely slow, so slow that you can even make it go to sleep easily. These problems are usually caused be an overload in your iPod's data. To fix this, I would recommend that you either clear up your device's memory or restore it, so you have a clean space for the jailbreak. Also, although I'm not a big fan of this, you could also try to rejailbreak it with Black ra1n. Not sure it'll work though.

- Q: I liked them until I forgot an electronic device in a pocket. Wash and extra rinse and it still didn't get wet enough to damage it. How can it get clothes clean like that?

- they only wash half as much per load as a top loader . They say they are more efficient , but that's probably because they only do half as much

Send your message to us

CMAX - WHEEL LOADER SERIE - 457 MODEL,All switches and auxiliary controls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords