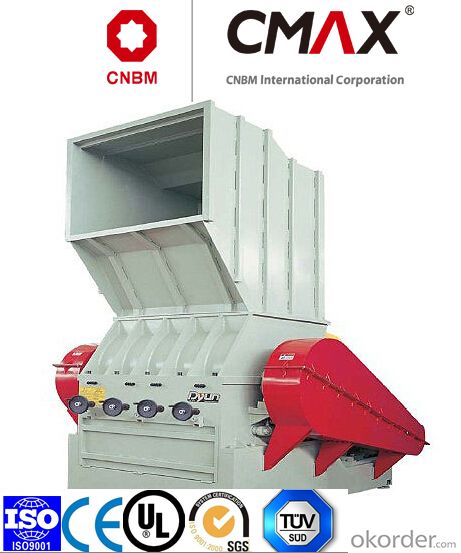

CMAX High Output CMAX Thin-film Crusher

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1.can solve the problem of width of sheet,platesand foam coil materical.

2.this serice add a set of haul-off device,two sets of press roller,air press controller.

3.the line speed can reach 30m/min

4.capacity is higher

5.main axis is processed with high quality steel after verifying the balance.

6.the rotor adopts 'V''type cutting technology

7.the CMAX-FP adopts box water cooling system,which avoid sticking the blade because of the heating of materical.

8.we can provide material collection device and powder separation system according to customer's requirements

Specifications

Certification: CE SGS,ISO9001,UL,TUV

1.High capacity

2.Good quality and reasonable price

Our Services

1) Presale service: Freely provide project designing, process designing, choosing suitable equipment for you.

2) Mediumsales service: Accompany you to complete the acceptance of the equipment,draft the construction scheme and detailed process, and complete process of export

3) Aftersales service: We sent engineer to the scene to guide installation, debugging and training operators.

4) we provide engineers available to service machinery overseas

product show

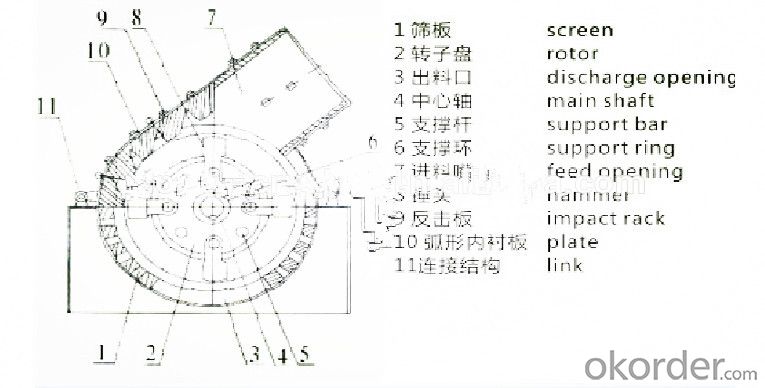

technical data

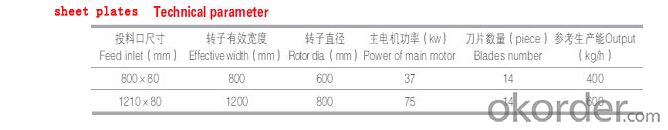

sheet plates technical

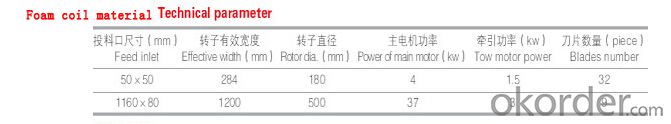

foam coil materical

FAQ:

*Q: What’s the price of this machine please?

*A: Dear customer, for each kind of our machines, we have lots of models.

Generally speaking, we design the production lines according to

different requirements of different machines from different customers.

Therefore, the prices are different. So please kindly inform us your requirements.

For example, the raw material, the output product size, capacity and etc.

The more detailed, the better. Our Engineers will design a suitable production line for you.

- Q: Points for attention of plastic recycling granulator

- 3. The feeding port of the granulator. No sundries such as iron are allowed in the vent hole. In order to avoid accidents, affecting production.Matters needing attention in working process of granulator1, pay attention to the body temperature change, with clean hands to touch the note left, immediately warming. Until the cops touch as normal.2, reducer bearing parts burning hand, or accompanied by noise should be timely overhaul, and add oil.

- Q: How many kinds of crusher are there? What are the main differences? Please explain them in detail

- Jaw crusher, impact crusher, cone crusher, hammer crusher, impact crusher, to roll crusher, composite crusher etc..

- Q: What is the noise produced by a plastic crusher?

- Low noise, mainly used for all kinds of thick wall plastic industry waste material, recycling scrap pieces, the thick and tough, large material (large head materials, large plastic pipe fittings, large diameter thick wall PE pipe, plastic packaging barrels, large bundles of plastic film,

- Q: How to calculate the crushing capacity of a coal crusher?What's the formula?

- Crusher because of improper use often leads to the phenomenon of death, so in the crusher, crushing the material, must pay attention the degree of uniformity of the material, there is the hardness of the material properly, if good, can be coupled with a process.

- Q: Working video of aluminium crusher

- The aluminum is not high enough, the crusher needs to consider separating from other metal, no video can't be delivered here. It needs the equipment to call me!

- Q: What kind of heating machine is better for the recycled plastics factory? How long does the crusher sink need to be cleaned?

- Your shaft is broken. Is it too deep at the bottom of the bar to eat too much? The exhaust is empty and the material is normal

- Q: How much does it cost to process a ton of plastic bottles?

- An overview of waste mineral water bottle is a polyester plastic products currently on the market, there is no feasible method for recycling, but the crushing, washing, drying after processing into pieces of plastic, it is an important raw material for spinning, the current market price per ton up to 7000 yuan. In Shandong, some of the waste plastics market, the supply of such products in short supply, some rely on recycling processing of such plastic production households, annual income of up to 20-30 yuan. Because this kind of plastic products have four seasons, and the production is simple and convenient, so the market is very broad, suitable for investment and production throughout the country, there are generally 100 square meters of open space. Two, the configuration of the equipment and is mainly composed of 45 types of plastic crusher (with 1.5 kW motor, the yield of 400 kg / hour), washing machine (7.5 kW motor), feeding machine (4 kW motor), washing machine (3 kW motor), dryer (7.5 kW motor, yield 4000 kg / when the small five institutions)

- Q: Why plastic crushers are closely related to environmental protection?

- Plastic recycling has developed, and that has important implications for environmental protection

- Q: How much does a small plastic crusher cost?

- Mainly depends on how much you want to yield, I hope I can help answer, do not forget to adopt

- Q: How much does it cost to run a disposable plastic basket factory?

- Fourth that's the raw material, like the black plastic basket. The main ingredients of this kind of product are Recycled HDPE and polypropylene. Estimated equipment and die investment is about three hundred thousand.

Send your message to us

CMAX High Output CMAX Thin-film Crusher

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords