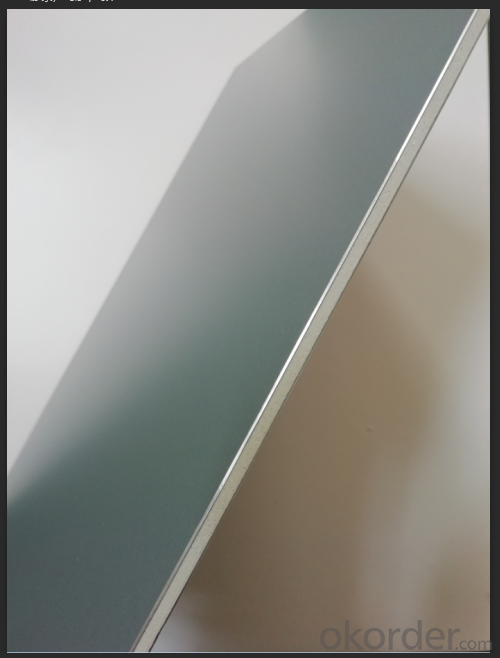

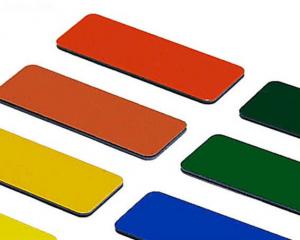

Class A2 fireproof board 、Aluminum composite panel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 40000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

The main product features:

First, our company can produce A2 fireproof board product specifications:

Available: PE/PVDF/FEVE/NANO

Thickness: 3-6mm

Width: 1220-1600mm

Aluminum skin thickness: 0.2-0.7m0

Two, product use

1, the subway station, high-speed rail station, train station, airport terminal, terminal and wall decoration;

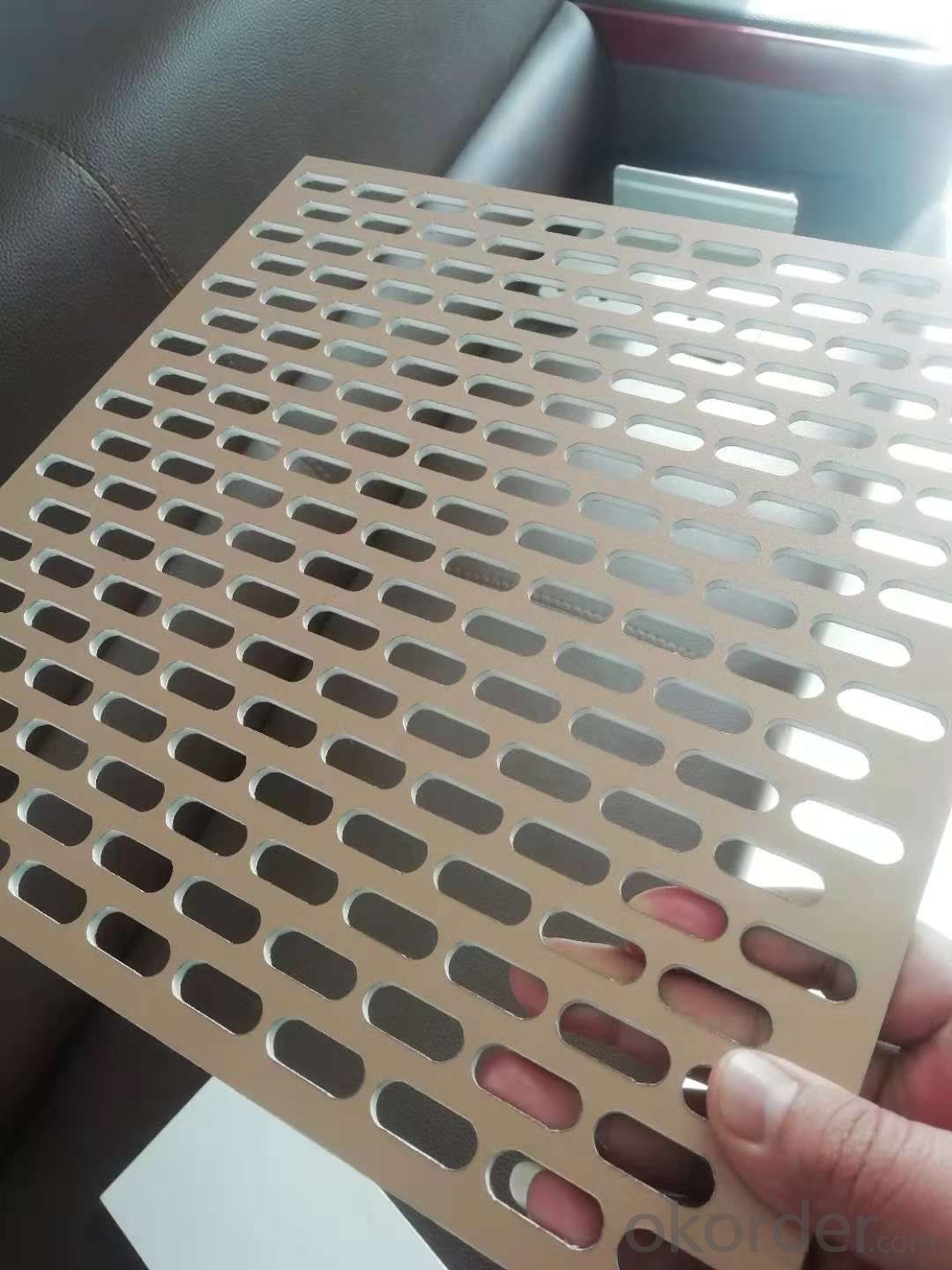

2, CBD business center, exhibition center, high-rise building building, office buildings, hotels, stadiums, senior residential building exterior decoration, billboards, shopping malls decoration panel;

3, large hospitals, medical equipment, beauty salons, health clubs, nursing homes, kindergartens and other external decoration.

Three, product performance and advantages:

1, excellent fire high cost

A grade fireproof performance fireproof composite board with high grade, is fireproof board, the flame sustained combustion time is zero.

1200 C no flames reached the high level a fireproof,

With the high quality production of keel partition system resistance limit reached more than 4 hours, the fire burning process can absorb a lot of heat, delay and elevated ambient temperature.

A fireproof composite board, stable and reliable quality, compared with other aluminum-plastic plate, light energy, moderate price.

Product surface can be coated with nano coating, more resistance, anti pollution, can achieve the self clean effect of natural rainwater utilization, from the modern high-rise large buildings in maintenance and maintenance costs.

2, high strength superior weatherability

A fireproof composite board has a strong weatherability and anti UV properties, acid resistance, alkali resistance, can withstand the harsh environment test, thermal expansion and contraction of small changes, the shrinkage rate is less than 0.2%, wet expansion rate less than 0.4%, can withstand the temperature of -80 DEG C -40. The coating product uses the international brand, color and gloss, and can provide up to 20 years of warranty does not fade.

A fireproof composite board has the advantages of light weight, compact structure, good stability, with wood like toughness. In compression, tensile, flexural and impact resistance, toughness and economic performance.

3, heat insulation and energy saving environmental protection and health

The characteristics of a fireproof composite plate inorganic core layer has pores is uniform and compact, the thermal conductivity of 0.216w/cm.k, ratio of lime sand brick cut (1.1w/cm.k) more insulation, saving energy consumption, make the bedroom maintain a comfortable environment and fresh air.

A fireproof composite board does not contain asbestos, formaldehyde, benzene and harmful radioactive elements, in case of fire, smoke-free, non-toxic, no smell. The production of materials for natural mineral and plant fiber, natural curing, the production process of low energy consumption, no row of dirt, energy saving and environmental protection, the use of surface off powder, its unique natural pore structure, can adjust the indoor temperature, and makes the room more comfortable office.

4, sound and light seismic heterogeneity

A sound insulation fireproof composite board to ensure the living environment quiet and elegant, the thickness of 3mm sheet insulation capacity of 29dB, double 4mm thick sheet partition system air sound is less than 42db, its unique pore structure is uniform and dense structure plate other incomparable

The surface density of a fireproof composite board for 0.8-12g/cm -, reduce the building load, can effectively reduce the earthquake resistant structure, foundation and structure of the main cost; while making building walls to reduce the weight of more than 60%, while increasing the use of the area 5-8%.

- Q: What are the specifications of the aluminum-plastic plate? What are the aluminum-plastic board manufacturers?

- The strength of the manufacturer should be all-round, comprehensive, not simply to have a number of production lines as a measure of the standard. The strength of the manufacturer should be reflected in the ability to strictly use raw materials, whether it can continue to provide high-quality products and their products focus and professional (how to make curtain wall with aluminum or plastic plate or to produce common logo Mainly with the board). The understanding of the overall strength of an enterprise requires a field trip to arrive at a comprehensive and accurate conclusion. Jiangxi Hongtai Hongtai Enterprise Group Co., Ltd. produces Yali Tai insulation board, the company was founded in 1995, is the first in the production and manufacture of aluminum-plastic plate one of the enterprises.

- Q: OKorder aluminum-plastic plate how much money, a little better, do with the external walls

- Outer Fluorocarbon aluminum-plastic board generally 90-160 yuan / square meters, depending on the level of the floor and how much use of aluminum-plastic panels, four or more recommendations with 4MM thick / 0.4MM aluminum, about 120 yuan / square Meter. Six or more best with the national standard plate 4MM thick / 0.5MM aluminum, about 145 yuan / square meter.

- Q: It is good for aluminum manufacturers of aluminum alloy cans

- Do you need aluminum or aluminum cans?

- Q: As long as the aluminum-plastic plate can fire it? Online and so on

- Non-flammable level is A-class, flame-retardant level is B-class, the other five levels such as flammable level.

- Q: What plastic glue can stick with the board?

- Aluminum plastic board and wood together with the glue with Wan Nengjiao and 502.

- Q: Home improvement, trouble annoying. Really know how much. Members of the senior, trouble to answer, the more detailed the better! To be easy to clean. Not sticky fumes. Heat is not flammable. So clean. The strength is slightly better.

- According to reports, the roller coated aluminum slab color bright, but only plain, and more so contaminated with smoke, relatively difficult to care; film is covered in a layer of film, color directly on the film, The This film has two kinds of imported and domestic, its thickness also affects the service life of aluminum plate. Drawing is a pattern processing, relatively beautiful.

- Q: On the report of the project price per square meter engineering requirements is to use 50 * 5 angle iron keel with 4mmA grade aluminum-plastic plate dry hanging

- Skeleton anchors should be made with embedded parts, in the absence of embedded parts in the case of post-embedded parts, embedded parts of the structural form to meet the design requirements, before the construction according to the project axis and the center line and the baseline level Embedded parts to check and check, the general allowable position size deviation of ± 20mm. Bolt to be carried out on-site drawing test to meet the strength requirements before use. If the location of embedded parts can not be used or leakage, should be based on the actual situation of the expansion bolts fixed post-embedded embedded parts of the program, and must be reported to the design unit approval, and should be done in the field pull test, Take good notes. The anchors are usually made up of buried plates and connecting corners, which are accurately marked on the centerline of the mullion, and then the holes are fixed and the centerline of the mullion leads to 0.8 Mm wire (both ends with the basket screw tightening) for signs control line. And then the level of the standard and the standard steel embedded parts, and then calculate the location of the connection angle code, in the buried plate on the crossed mark, the same mullion connected to the same side of the corner position to pull the line detection, can not be biased. Corner position to determine, the corner code according to this location welding to the buried floor, the width and length of the weld to meet the design requirements, welding after welding to do rust treatment, the general brushing antirust paint twice.

- Q: On the Kyrgyzstan and auspicious brand of aluminum plastic plate which is good

- Now the material is not much, auspicious brand can be a good point.

- Q: Home decoration, please curtain wall with aluminum plate how much the price per flat

- According to my knowledge, I say ~ aluminum-plastic composite board is a chemically treated aluminum plate for the surface material, with polyethylene plastic as the core material, in the special aluminum-plastic plate production equipment from the processing of composite materials The The unique performance of the aluminum-plastic composite panel itself determines its wide range of uses: it can be used for building facades, curtain wall panels, retrofits of old buildings, interior walls and ceilings, advertising signs, display stands, engineering. Aluminum-plastic composite panels in the country has been widely used, belonging to a new type of building decoration materials. I know that the general price is between 80 to 120 yuan This is what I know the information, I hope you have a reference role ~

- Q: Seeking professionals to answer the ceiling gypsum board composite board solid wood board MDF aluminum panel panel What is the difference Thank you

- Gypsum board: as the name suggests, with gypsum produced board, decorative;

Send your message to us

Class A2 fireproof board 、Aluminum composite panel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 40000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords