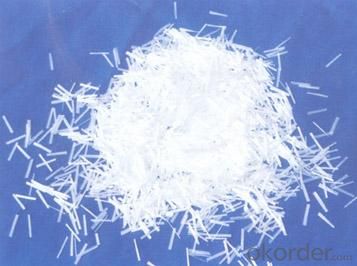

Chopped Strand Fiberglass E-Glass Fiberglass Chopped Strands for BMC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introductions

E-Glass Fiber Glass Chopped Strands For BMC are compatible with unsaturated polyester, epoxy resin and phenolic resins.

The end-use applications include transportation, building & construction, electronic & electrical, mechanical, and light industry.

2.Product Features

Extremely low resin demand, delivering low viscosity to BMC paste

High impact strength; High LOI rate

High strand stiffness; Compatible with rubber

3.Product Specifications

Property | Fibre diameter | Moisture Content | Size Content | Chop |

(%) | (%) | (%) | (%) | |

Mathods | IS01888 | ISO3344 | ISO1887 | |

3mm | ±10 | ≤3.0 | 0.1±0.05 | 98 |

6mm | ||||

9mm | ||||

12mm |

Special specification can be produce according to customer requirements.

4.FAQ

Packaging:

Each bag can be taken (15-25kgs)。 Could also take a big container bag.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: Is fiberglass chopped strand resistant to UV radiation?

- Yes, fiberglass chopped strand is generally resistant to UV radiation. The glass fibers in fiberglass are inherently UV stable and do not degrade or weaken significantly when exposed to sunlight or other UV sources. However, it is important to note that prolonged and direct exposure to intense UV radiation can still cause some minor degradation over time. Hence, it is recommended to use proper coatings or additives to enhance the UV resistance of fiberglass chopped strand in outdoor applications.

- Q: Can glass fiber be recycle? There are raw silk and shred silk.. .

- Made into reinforced material

- Q: How to make glass fiber mould

- The roving of roving is made up of parallel filament or parallel monofilament. According to the composition of glass, roving can be divided into alkali free glass roving and medium alkali glass roving.

- Q: How is the quality of fiberglass chopped strand ensured during production?

- The production process of fiberglass chopped strand incorporates various measures to guarantee its quality. To begin with, strict testing is carried out on the raw materials, including glass fibers, resin, and additives, to ensure they meet the necessary specifications and standards. Throughout the manufacturing process, regular calibration and maintenance of the production equipment are conducted to ensure accurate and consistent outcomes. Close monitoring and control of parameters such as temperature, pressure, and speed are employed to achieve the desired quality of chopped strand. Quality control checks are performed at different stages of production. These checks involve visually inspecting the finished product to identify any defects or inconsistencies. Additionally, samples are taken from each batch and subjected to a range of tests, including tensile strength, fiber diameter, moisture content, and impurity levels. These tests serve to verify the physical and chemical properties of the chopped strand and ensure it meets the required standards. In addition, production facilities often implement quality management systems, such as ISO 9001, to ensure adherence to established protocols and procedures. These systems aid in maintaining consistency, traceability, and continuous improvement in the production process. In conclusion, the quality of fiberglass chopped strand is guaranteed through rigorous testing of raw materials, meticulous control of the production process, thorough quality checks, and adherence to quality management systems. These measures ensure the production of a reliable and consistent product that meets the desired specifications and standards.

- Q: What are the typical processing challenges when using fiberglass chopped strand composites?

- There are several common processing challenges that may arise when using fiberglass chopped strand composites. One of the main challenges is ensuring consistent dispersion of the fibers throughout the composite material. Due to the short lengths of the fibers, it can be difficult to evenly distribute them within the resin matrix. This can result in areas with low fiber content, leading to reduced mechanical properties and potential weaknesses in the final product. Another challenge is managing the processing temperature. Fiberglass chopped strand composites typically require higher temperatures compared to other materials. This poses challenges in terms of selecting suitable processing equipment and maintaining the temperature within the optimal range throughout the manufacturing process. Failure to control the temperature can result in poor resin flow, incomplete curing, or even degradation of the fibers. Moreover, the abrasive nature of fiberglass can cause increased wear and tear on processing equipment. The sharp edges of the chopped fibers can lead to excessive wear on molds, dies, and other components of the production machinery. Regular maintenance and replacement of parts are necessary, adding to the overall complexity and cost of the manufacturing process. Additionally, handling and storing chopped strand composites can be challenging. The fibers are prone to breakage and tangling, making it difficult to handle and feed them into the processing equipment. Proper storage conditions, such as maintaining low humidity levels, are crucial to prevent moisture absorption by the fibers, which can negatively impact their performance and adhesion to the resin matrix. Lastly, achieving consistent and reliable bonding between the fibers and the resin matrix can be a challenge. The short lengths of the chopped fibers make it more difficult to establish a strong bond, resulting in reduced mechanical strength and potential delamination issues in the final product. Special attention must be given to the resin formulation and processing parameters to ensure optimal adhesion between the fibers and the matrix. In conclusion, fiberglass chopped strand composites offer numerous advantages, but they also present several processing challenges that require careful attention to achieve high-quality and reliable end products.

- Q: Is fiberglass chopped strand suitable for use in corrosive environments?

- Fiberglass chopped strand is generally not considered suitable for use in corrosive environments. While fiberglass itself is resistant to many chemicals and corrosion, the chopped strand form typically lacks the necessary protection against corrosive elements. The chopped strand is composed of small, individual fibers that are randomly dispersed and held together with a binder. This binder is often made of a thermosetting resin, such as polyester or epoxy. While these resins provide some level of protection against corrosion, they are not as effective as other materials specifically designed for corrosive environments. In corrosive environments, it is recommended to use materials specifically engineered to withstand the specific corrosive agents. Examples of such materials include fiberglass reinforced with vinyl ester or other specialized resins, or corrosion-resistant metals such as stainless steel or titanium. Therefore, if you are looking for a material to be used in corrosive environments, it is advisable to consult with experts or suppliers who can recommend suitable alternatives specifically designed for such conditions.

- Q: Is fiberglass chopped strand biodegradable?

- Fiberglass chopped strand does not possess biodegradability. It comprises glass fibers and a polymer resin, forming a reinforced plastic. The glass fibers do not naturally disintegrate, and the polymer resin is commonly non-biodegradable too. Consequently, fiberglass chopped strand will endure in the environment for an extended period and will not undergo decomposition via natural mechanisms.

- Q: Is fiberglass chopped strand resistant to chemicals?

- Indeed, fiberglass chopped strand typically possesses a high degree of chemical resistance. Comprised of glass fibers and a polymer matrix, fiberglass boasts exceptional durability against a broad spectrum of chemicals. It can endure exposure to a wide array of acids, alkalis, solvents, and other corrosive substances without undergoing substantial deterioration or harm. Nevertheless, the precise chemical resistance of fiberglass chopped strand may fluctuate based on the particular resin employed, the manufacturing procedure, and the specific chemicals employed. It is prudent to consult the manufacturer's specifications or undertake chemical compatibility tests to ascertain the appropriateness of fiberglass chopped strand for a given chemical application.

- Q: Is fiberglass chopped strand suitable for the production of roofing materials?

- Yes, fiberglass chopped strand is suitable for the production of roofing materials. It offers excellent strength, durability, and resistance to weather conditions, making it an ideal choice for roofing applications. Additionally, its lightweight nature allows for easy installation and reduces the overall weight of the roof.

- Q: Can fiberglass chopped strand be used in electrical grounding applications?

- Using fiberglass chopped strand in electrical grounding applications is not advisable. Fiberglass, being a non-conductive material, lacks the ability to conduct electricity. In order to safely dissipate electrical charges, a conductive material is necessary. Copper or other metals are commonly utilized in such scenarios due to their excellent electrical conductivity.

Send your message to us

Chopped Strand Fiberglass E-Glass Fiberglass Chopped Strands for BMC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords