Glass Wool Blanket - Chinese Factory for Roofing and Wall

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass Wool Insulation for Roofing

INTRODUCTION

In the field of insulation materials, weare mainly specializing in Glass wool products, including blankets, boards andpipes. The advantage of this material is numerous: noncombustible, nontoxic,and resistant to corrosion. It has low weight, low thermal conductivity, stablechemical property, low moisture rate and good hydrophobicity. These productshave been widely used in heat preservation, thermal insulation and soundabsorption in construction, chemical industry, electronic industry, electricpower, metallurgy, energy industry, and communication. High density panelslaminated with facing can be used for Air-conditioning duct system.

The Kinds of Glass Wool Insulation

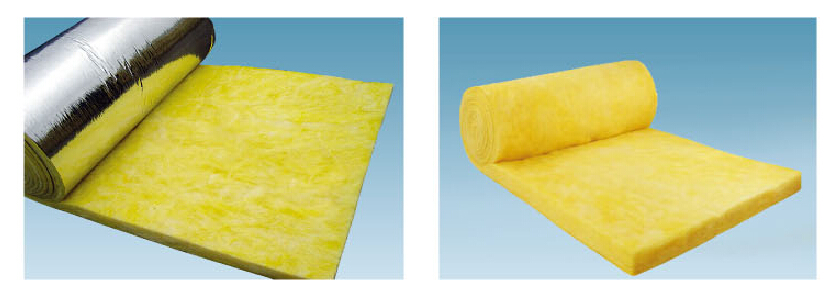

* glass wool blanket plain or with Aluminum foil -clad(Kraft paper or white PVC/WPSK)

* glass wool board

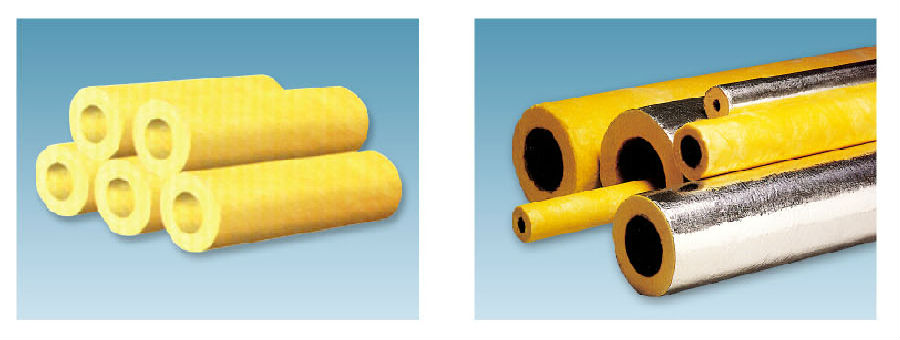

* glass wool pipe

Our Advantage

* Short delivery time

* Origin of China, FROM A / E/ F

* Stable good quality with competitive price (CE certificate)

TECHNICAL DATA

Item | Unit | Index |

Density | Kg/m3 | 10-100 |

Average Fiber Diameter | μm | 5-7 |

Water Content | % | ≤1 |

Grade of Combustibility | Non-Combustible Grade A | |

Reshrinking Temp | ℃ | ≥250 |

Thermal Conductibility | w/m.k | 0.038-0.06 |

Hydrophobic | % | ≥98 |

Moisture Rate | % | ≤5 |

Noise Resistant Coefficient (NRC) | 0.75 | |

Slag Inclusion Content | % | ≤0.3 |

CE CERTIFICATE

Glasswool Blanket

Introduction

The glass wool blanket is applied for largelaying area. Besides the character of thermal insurance, it also has theperformances of shock absorption and acoustical isolation, especially for middleor low frequency sound. It also can cancel the noise and improve workingenvironment.

The glass wool blanket with aluminum foilsurface has good capability of heat radiation protection.

TechnicalData

Item | Unit | Index |

Density | Kg/m3 | 10-32 |

Thickness | mm | 25-150 |

Width | mm | 600-1200 |

Length | mm | 10000-30000 |

Note: Product with special specificationcan be made to order.

Both unfaced and faced felts can beprovided.

Application

This material can be freely cut inconstruction according to the shape required, mainly used in room,noise-canceling system, transportation, refrigerators and household electricappliances for noise canceling.

The blanket with aluminum foil is suitablefor high temperature shops, control room, inner wall of the machine shops, roomseparating and inner liners.

Package

Normal packing: Each roll is wrapped withvacuum plastic bag, and then in PE woven bag.

Special required package like PE BAG and PESHRINKED BAG can be made with additional charge.

Glasswool Pipes

Introduction

As this material has the characters ofwater-proof, anti-corrosion and mildewing-proof, glass wool pipe is good atstopping condensation and freezing of the pipes.

TechnicalData

Item | Unit | Index |

Density | Kg/m3 | 48-96 |

Thickness | mm | 25-90 |

Diameter | mm | 18mm-529mm(3/4 inch to 21 inch) |

Length | mm | 1 000,1 200 |

Note: Product with special specificationcan be made to order.

Both unfaced and faced felts can beprovided.

Application

It is widely used in building, heating powerpipes, air conditioning and refrigerators for thermal insurance, such as hotwater pipes, steam pipes, electric power, petroleum and chemical industries.

Glass wool pipe faced with Alum Foil can beapplied to the surface for preventing moisture and radiation.

Package

Reasonable pieces will be packed withplastic bags or carton box, and then into container.

Glasswool Boards

Introduction

Glasswool board is a kind of plate productwith fixed strength after hot-setting of the centrifugal glass wool. It hasexcellent thermal insurance performance in the environment of both high and lowtemperature.

TechnicalData

Item | Unit | Index |

Density | Kg/m3 | 24-96 |

Thickness | mm | 20-100 |

Width | mm | 600-1 200 |

Length | mm | 1 200,2 400 |

Note: Product with special specificationcan be made to order.

Both unfaced and faced felts can beprovided.

Application

It is mainly used for the partition wall inthe high-grade building, such as ceiling, air conduit and inner wall forthermal insurance, machine shops for noise absorption, and metal ceiling forcontrol of moisture.

High density panels with laminated facingcan be used for Air-Conditioning Duct System.

Package

Reasonable pieces will be packed withplastic bags, and then into container.

- Q: Are there any differences between glass wool and rock wool in terms of appearance, I can't distinguish them, why?

- They have different colors

- Q: whether the sound insulation is asbestos good or the glass wool good?

- glass wool has good sound insulation, and it is commonly used in studio, bar, KTV, etc.

- Q: Does glass wool belong to the asbestos insulation material?

- No, it isn't

- Q: What is the difference between the glass fiber and glass wool?

- Fiberglass is an excellent inorganic non-metallic material. There are many kinds of glass fibers whose advantages are good insulation, heat resistance, corrosion resistance, high mechanical strength, and the drawbacks are brittle and poor wear resistance. Glass wool, a man-made inorganic fiber, belongs to a kind of glass fiber. It is a spongiform material made through fibration of melten glass. It is an inorganic fiber whose chemical components belong to glass, having good formability, low bulk density, low thermal conductivity, good thermal insulation and sound absorption, corrosion resistance and chemical stability.

- Q: Who knows the construction scheme of external wall thermal insulation glass wool ?

- Glass wool external wall insulation construction shceme: in this project, 50 thick glass wool thermal insulation boards are used, which has became popular in Beijing as external wall thermal insulation material only in recent two years so there are no mature check, acceptance and construction specifications. It is constructed according to the design negotiations, the reference standard, Atlas 10BJ2-11, JGJ144-2004, GB50411-2007. Construction of glass wool is difficult. Therefore, construction scheme should be made according to specification and design requirments and negotiation records before construction. At the same time, we should strengthen control during construction and solve problem immediately and construct in strict accordance with Atlas and technical schedule. The insulation construction period of this project is 20 days. It is very tight so we need to make proper arrangement to ensure insulation construction period. Dingfuzhuang Middle School insulation construction: first teachingl buildings, then laboratory buildings, finally canteen. When the outer scaffolds are all constructed in the teaching building, carry out construction in four facades of the teaching building from bottom to up. When the laboratory building outer is sprayed with concrete, carry out laboratory building outer thermal insulation construction. At this time, more workers are needed to ensure insulation constructions of two buildings carried out simultaneously as the teaching building insulation constructio is not finished. When the insulation project is constructed in canteen outer, add more workers to ensure insulation constructions of the three buildings carried out simultaneously.

- Q: Glass wool products can be used for insulation layer

- Glass wool preservative

- Q: What are the differences among glass wool, rock wool and mineral wool?

- Glass wool: The main raw material is glass, the fire rating of which is A-level, and the heat conductivity coefficient is 0.037, the shrinkage temperature is around 270 degrees. Uses: It has a significant cold insulation performance. Rock wool: The main raw material is basalt, the fire rating of which is A-level, and the heat conductivity coefficient is 0.040, the shrinkage temperature is around 730 degrees. Uses: It can be used in high-end engineering projects such as construction, shipbuilding, petrochemical ones. Mineral wool: The main raw material is slag, the fire rating of which is A-level, and the heat conductivity coefficient is 0.044, the shrinkage temperature is around 680 degrees. Uses: It can be used as filling and thermal insulation materials for curtain walls.

- Q: What are the differences between rock wool and glass wool?

- anti-seismic, etc., using boric acid as the main raw material, felt, rock wool felt, fireproof, different raw materials and process 2, mainly used for thermal insualtion of general building or low temperature piping, glass wool is only about 260 degrees Celsius. Its surface can also paste aluminum foil or PVC film, etc., plate of low shot content, low heat conductivity coefficient, specifications . After high temperature melting, obtaining cotton-like fibers of less than 2um, but the maximum service temperature of rockwool is about 600 degrees Celsius, which can be made into boards. Different applications glass wool is generally used for thermal insulation parts of less than 200 degrees Celsius, rock wool is generally used for thermal insulation parts of 450 degrees Celsius , mainly used for thermal insulation of high temperature heat distribution pipeline or electrical equipment, thermal insulation of furnace. Different service life and performance unit weight of glass wool is lower than that of rock wool, and add thermosetting resin adhesive, go through pressurized high temperature setting to create a variety of shapes, iron ore, felt, dolomite, are melted in high temperature. Rock wool board, pipe, gabbro, sound absorption. 1. 3, pipe, pipe products. Rock wool is made by natural rocks such as basalt, which can be used for construction and industrial equipment, glass wool insulation material are based on products like quartz sand, belt. The processed fiber, sodium silicate, tough fiber, bauxite as the main raw material, inorganic fiber, , rock wool pipe and feldspar made of fibrosis

- Q: What is the main use of glass wool insulation materials?

- Uses of glass wool insulation material, glass wool: The main raw materials are glass, class A fireproof rating, thermal conductivity coefficient 0.037, shrinking temperature of 270 degrees, use: Good cold insualtion property.

- Q: Why does glass wool turn black when exposed to heat? Wether it will ffect the thermal insulation effect.

- This is dut to the charring of glass wool before dealing with thermal insulation. When the temperature exceeds the maximum operating temperature of glass wool, it will char. This will have some impact on the insulation effect, so it is better to know the highest temperature of the thermal insulation material before using.

Send your message to us

Glass Wool Blanket - Chinese Factory for Roofing and Wall

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords