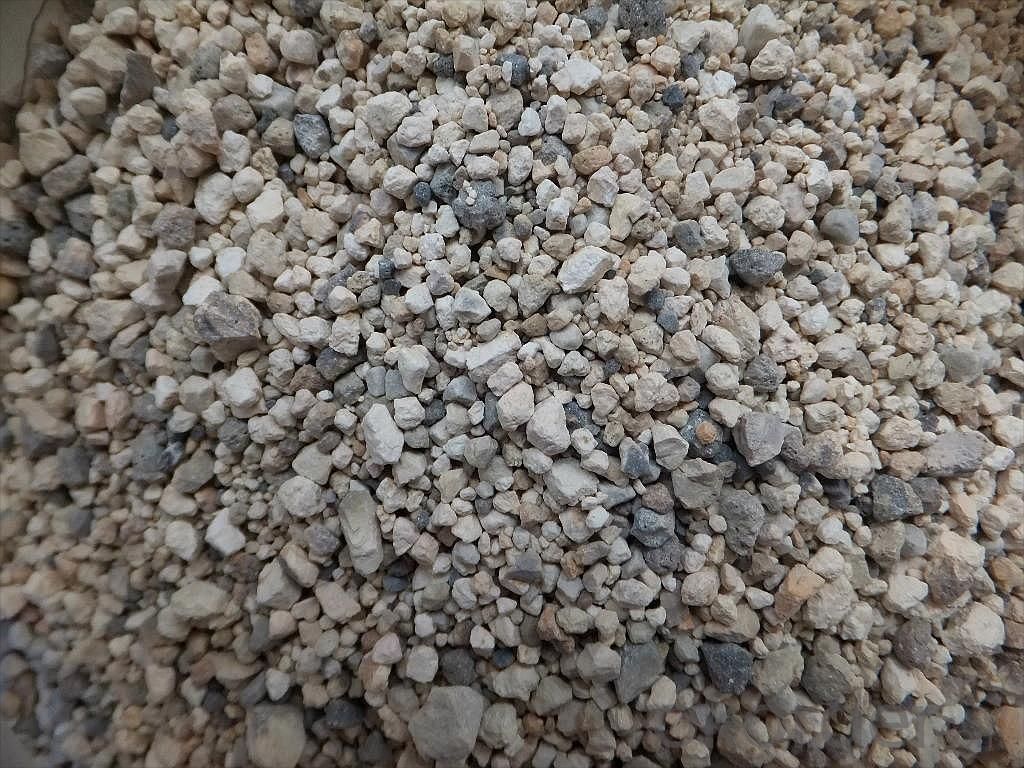

Raw Materials for Refractory:Chinese Calcined Bauxite with the Lowest Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

| Items | Al2O3 | Fe2O3 | B.D. | K2O+Na2O | CaO+Mgo | TiO2 |

| 88 | 88%min | 1.5%max | 3.25min | 0.25%max | 0.4%max | 3.8%max |

| 87 | 87%min | 1.6%max | 3.20min | 0.25%max | 0.4%max | 3.8%max |

| 86 | 86%min | 1.8%max | 3.15min | 0.3%max | 0.5%max | 4%max |

| 85 | 85%min | 2.0%max | 3.10min | 0.3%max | 0.5%max | 4%max |

| 83 | 83%min | 2.0%max | 3.05min | 0.3%max | 0.5%max | 4%max |

| 80 | 80%min | 2.0%max | 3.0min | 0.3%max | 0.5%max | 4%max |

| 78 | 75-78% | 2.0%max | 2.8-2.9 | 0.3%max | 0.5%max | 4%max |

Size:

0-1mm,1-3mm,3-5mm,5-8mm,8-10mm,200mesh,325mesh or as your request.

Packaging & Delivery

| Packaging Details: | In 25KG bags;1MT/1.25MT/1.35MT bags or as your requirements. |

| Delivery Detail: | 15-30 days after contract |

Quick Details

| Place of Origin: | Shanxi, China (Mainland) | Shape: | Block | Material: | Alumina Block |

| SiO2 Content (%): | 5-19% | Al2O3 Content (%): | 75-89% | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) |

| CrO Content (%): | None | SiC Content (%): | None | Model Number: | 78,80,83,85,86,87,88,89 |

| Brand Name: | CNBM | Fe2O3: | 2%max | K2O+Na2O: | 0.25-0.4% |

| CaO+MgO: | 0.4-0.6% | Bulk Density: | 2.8-3.30 |

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: Does anyone know the refractory temperature of fire-resistant glass?

- Ordinary glass will be completely liquefied in the furnace of about 1100 degrees for half an hour and will not deform below 600 degrees. toughened glass fire-resistant glass is the product of ordinary glass after being processed Glass will mainly burst after encountering fire. When unevenly heated or encountering sudden drastic changes in temperature, ordinary glass will burst if the sharp temperature difference is over 70-120 degrees and toughened glass will burst at 200 degrees. It is not yet clear of the bursting temperature for the refractory glass. (I hope this answer can help you!) Hope you adopt !)

- Q: What is the difference in the nature between the refractory material and thermal?insulation?material

- thermal?insulation?material is a material which has a strong impedance to the heat flow. the nature of the material requires that the material can isolate the delivery of thermal, and the low heat conductivity coefficient and expansion coefficient of the non-metal material.refractory is good in heat resisitance and chamical erosion but not high temperature resistance. Requirements on nature is still in high temperature.

- Q: What's the classification of refractory material?

- Magnesium aluminum is complex and mainly seeing what classification standard is like according to the appearance shape can be divided into two categories, setting and not setting according to the acid alkali can be divided into acidic, magnesia, high aluminum, ramming expected, spinel, spray coating, plastic, just the quality of the jade, daub material according to the chemical composition is divided into, such as clay, neutral and alkaline according to the operation mode can be divided into different castable, magnesium, calcium, magnesium chrome

- Q: What's the material of electrical fire prevention board?

- Industrial electrical fire prevention board is mainly aimed at fire protection and thermal insulation. Iron plate is electrically conductive with good thermal conductivity, which will cause the result that the equipment is not insulated and suffers larger superheating surface! ! ! !

- Q: What kind of refractories do the anode baking furnace use?

- 5% volume density. 2 , The application results show that it has the energy-saving effect. 4, Withstand voltage strength. The 50MPa prebaked anode baking furnace furnace wall replaces traditional small special-shaped brick with steel fibre reinforced castable precast block: The aluminum content is 45-60%. The iron content is less than 1. I know someone uses andalusite bricks. This method, under the condition of not changing the roasting technique , has excellent resistance to CO. If there are investors, you can complete the overhaul and reconstruction work of anode baking furnace, which is still a precedent in the country. The andalusite bricks are significantly better than clay bricks. The volume density of 5% of it is 2.25. The compressive strength of 40MPa aluminum content is 60%, and the iron content is less than 1. The andalusite is more denser in the structure. Physical and chemical indicators are as following: it has a good anti-corrosive of exhaust gas Na2O. This is because its chemical composition and mineral composition are very suitable for anode baking furnace, which has long life and easy construction and other characteristics.

- Q: What is high alumina refractory?

- It refers to inorganic non-metallic material with refractoriness of higher than 1580℃. Refractoriness refers to the celsius temperature that the cone-shaped refractory sample without load can resist, and under which the sample won't soften and melt down. Refractory material appears together with high temperature technology, and roughly dates from the Middle Bronze age. In the Eastern Han Dynasty (AD25~AD220) of China, fireclay refractories has been used as furnace refractories and saggers for making porcelains. In the early 20th century, refractory material develops toward the direction of high purity, high dense and ultra high temperature products, and meanwhile unshaped refractory and refractory fiber with no need of firing at all and with low energy consumption appear.

- Q: What's the type of fire proofing thermal insulation materials?

- Hello! Fire proofing thermal insulation material can be classified as inorganic thermal insulation material and composite thermal insulation material. According to the form, it can be divided into fibrous veneer, mineral wool, rock wool, glass wool, aluminum silicate cotton, ceramic fiber, microporous diatomite, calcium silicate, expanded perlite, expanded vermiculite, aerated concrete, bubble foam glass, ash, glass, clay, foam concrete, and pasted paste powder polystyrene particles insulation pulp, etc. They are characterized by flame retardancy and fire proofing and thus can be used in buildings with high fire proofing class. Among them, calcium silicate, aluminum silicate and asbestos can also be used for the thermal insulation for heat supply pipelines.

- Q: Development trend of refractory industry

- China announced that from 2004 January, the export of most refractory raw materials will be cancelled, and the export of finished products will also reduce the tax rebate rate. This means that important raw materials for further export restrictions, some developed countries dependent on imports of China's refractory materials and products of the refractories industry will have a major impact. In order to reduce costs, they will move their factories to Chinese, which is the development of Chinese refractories industry will also be an important opportunity. In addition, the convenience of communication and transportation, the change of the international market and the increase of e-commerce have also brought good opportunities to the development of refractory industry.

- Q: What kind of materials are needed to make refractory bricks?

- Refractory materials generally refer to inorganic non-metallic materials with fire resistance above 1580℃. It plays an important role in metallurgy, nonferrous metals, chemical engineering, ceramics, and industrial production. Different industry needs different materials. You can turn to the knowledgeable internet.

Send your message to us

Raw Materials for Refractory:Chinese Calcined Bauxite with the Lowest Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords