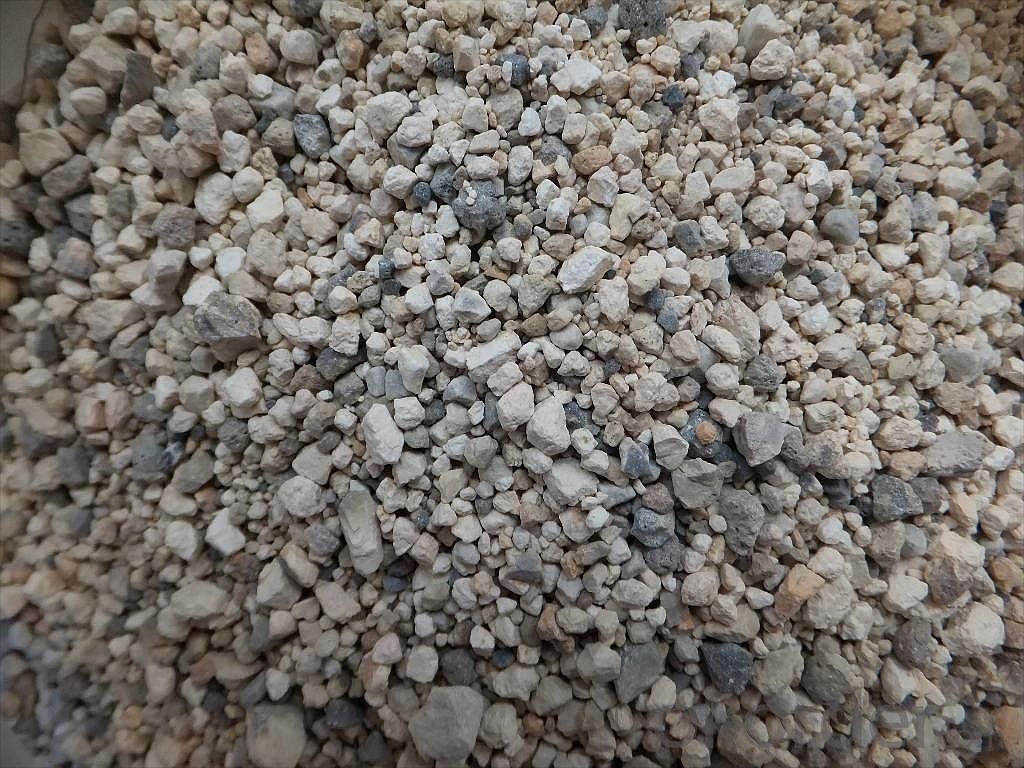

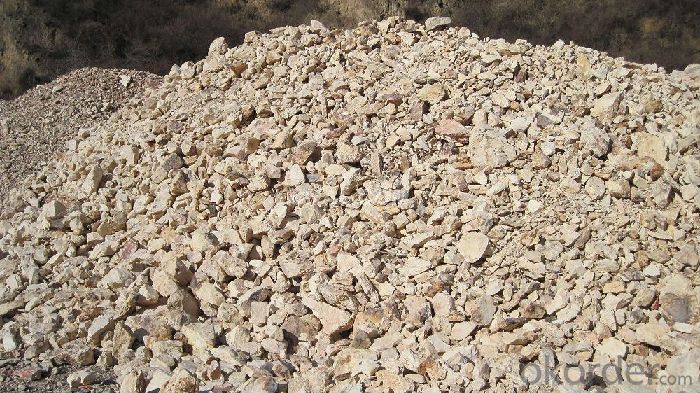

80% Round Kiln Alumina Calcined Bauxite Refractory Raw Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

80% Round Kiln Alumina Calcined Bauxite Refractory Raw Material

Specifications

1. We directly supply calcined bauxite

2. Al2O3:70%/75%/80%/85%/86%/88%/90%

3. Size:0-1-3-5-8-10/200mesh/325mesh/400mesh/500mesh

Size:

Lumps /Grains:0-1mm,1-3mm,3-5mm,5-8mm /Powders:100mesh, 200mesh,325mesh

Product Description:

Bauxite, alumina or bauxite miner , main ingredients are aluminum oxide, hydrate alumina containing impurities,

is an earthy mineral.White or grey, brown yellow or light red by iron.From 4 to 3.9 g/cm3 density, hardness, 1 ~ 3, opaque, very brittle.

Very difficult to melt.Insoluble in water, soluble in sulfuric acid, sodium hydroxide solution.Mainly used for aluminium, refractory material.

Calcined Bauxite Grade:

Shaft Kiln Bauxite

Rotarty Kiln Bauxite

Round Kiln Bauxite

Packaging & Delivery

Packaging Details: In bulk or in 1-1.25mr bag

Product Pictures:

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: Does anyone know the characteristics of refractory for glass kiln?

- The characteristics of refractory for glass kiln: First, it can well resist the erosion of glass?fusant and gas actor, and has sufficiently high load softening temperature and thermal stability. Usually we hope the refractories of all parts of the furnace will has no partial early erosion phenomenon to ensure that the entire furnace has a sufficiently long service life. However, due to the different mechanical, physical and chemical conditions of different parts of glass furnace, the performance of refractories should adapt to the glass furnace thereto and at the same time has no adverse effect on the adjacent other kinds of brick materials. Besides, we should consider the price of brick material, we should try to consider using commonly used stereotypes bricks of standard sizes which is cheap and quickly supplied by the warehouse. The damage of glass melting furnace lining is mainly due to chemical erosion, assisted by thermal stress. The degree and speed of chemical erosion is closely related to the applied parts, furnace temperature and melting glass varieties, and of course, the quality of the lining itself is also crucial. The nature of refractories using in the glass furnace has a very significant impact on the operation of glass melting furnace and the quality of glass. The application of poor main beam refractories will not only cause frequent shutdown for maintenance, limiting melting temperature, lowering furnace output, but also shorten the life of the furnace, and make glass has a variety of defects (stripes, stones, etc.), lower the quality of the glass. Here are the description of the nature and purpose of commonly used refractory in glass furnace.

- Q: What are the fire endurance requirements of class A fire resistant door ?

- Fire endurance of class A fire resistant door is 1.5h. According to the latest fire door requirements, in FMA FMB FMC three forms, A, B and C represent categories, such as FMA on behalf of Class A fire doors (ie thermal insulation fireproof door). Fire endurances of class A,B and C fire doors are 0.5 1.0 1.5 2.0 3.0. Therefore, the fire resistance of fire door needs to be designed and the design paper will make it clear in general.

- Q: What's the fire endurance of fire windows?

- Fire endurance of fire doors and fire windows stipulated by the fire prevention norm: Fire endurance of A class fire door or fire window is 1.2h rather than 1.5h, and fire endurance of B class fire door or fire window is 0.9h rather than 1.0h. Fire prevention code doesn't explicitly state that the fire door has thermal insulation function, so it can definitely be interpreted that the fire door only has fire integrity. For the fire door without heat-shielding performance, at certain distance from the unexposed surface, it has strong thermal radiation and is easy to hurt people. For the A class thermal insulating fire door, its fire integrity is 0.1h shorter than that of the corresponding fire door stipulated in the specification, but its heat-shielding performance and integrality is improved. All in all, compared with the specification that the fire integrity of the A class fire door should be 0.6h, it has much more improved its performance.

- Q: I know which material is the fire resistance rolling shutter door

- Fire resistance rolling shutter door and ordinary roller shutter are basically same, the differences are: Its inner and outer sides are generally made of galvanized iron sheet, filling asbestos fireproofing material betwwen two layers of fire resistance rolling shutter door, and some fire shutter doors can be interlocked with the relevant fire control system, when the breaking out of fire , it can automatically "half-drop" and "full drop".

- Q: As for fireproofing material rock wool and glass wool, which one is better?

- Rock wool board and glass?wool?board are a kind of new construction thermal insulation material, it's widely applied in construction and has replaced traditional thermal insulation material to some degree. With the gradually deepening study of rock wool board, glass wool board, we can find that these insulation materials have advantages in many aspects but there are also many deficiencies, particularly there exists a lot of controversy about the impact on the human body. The production process of rock wool board and glass?wool?board usually includes: after melting in high temperature of rock or glass, inorganic fiber is produced by high-speed centrifugation equipment, and at the same time add binder,dust?laying?oil,silicone oil at certain proportion, then produce sheet material according to different requirements. It has good thermal insulation properties, mechanical?property, sound absorption characteristics, belong to incombustible?material and is cheap. In general, insulation, security and economy should not be contradictory, three aspects should be taken into account, balanced chosen and developed. Rock wool board and glass wool board and other such materials should be properly selected and applied to the appropriate structure, so that the choice of material will play their strengths and avoid their weaknesses.

- Q: what kind of fireproof materials is used for high rise buildings?

- steel is recommended As a form of high-rise building structure, steel is widely used especially in the ultra-high-rise and long span construction showing strong vitality, for its high strength, light weight, and good extensibility, resistance to shock and short construction period. The mechanical strength of steel decreases with rising temperature at about 5000 ℃, decreasing about 40%-50%. the mechanical properties of steel, such as yield points, compressive strength, elastic modulus, and load capabilities have declined rapidly , quickly losing their ability to support, leading to building collapse. Therefore, it is imperative to protect steel structures. Brushing or spraying the coating on the surface of steel structure to prevent burning and insulate heat. It also prevents undermining the rolled steel from rapid temperature elevation and avoid collapse of building for lose of supporting capacities.

- Q: Manganese steel belongs to refractories

- NO!

- Q: What types does soft fire prevention materials have?

- Types of fire resistant species. Mainly listed as follows: finishing fire retardant paint, component fire retardant coating, fire-resistant coating for steel structure and othe kinds of fire retardant coating. Flame retardant plastics and its products, textiles, building materials, flame retardant fabric and exterior wall thermal insulation system products, floor materials, such as various types of fire prevention materials;Fire prevention board, fire doors, fire prevention, fire shutter, fire glass window frame, elevator doors, ventilation pipes, fire blocking material, fire smoke exhaust fan and other kinds of artifacts (resistance) fire prevention. Indicators of judging fire mainly include: difficult to fire, ignition, smoke toxicity, smoke density, heat release and flue gas; fireproof performance, combustion performance and combustion heat value, fire resistance, high temperature resistance, fire rating, etc. And some specific parameter is needed to use professional testing instrument to judge, but to the inorganic lab for understanding, fire prevention level test result accuracy.

- Q: What is the difference between the fire?rating and the fire resistant level of the fire-fighting equipment?

- Hello there. Fire rating and fire-fighting rating are the misnomer to the building fire resistant level. The building fire risk is measured by fire resistant level. The article 3.2.1 and 5.1.7 of "Architectural design code for fire protection" have made provision respectively on the fire resistant level of plant (the storeroom) and civil construction. Article 3.0.2 of "Code for fire protection design of tall buildings" has made provisions on the fire resistant level of tall buildings. As for the warehouse building "category malonate", it refers to one of the fire risk of goods storage, which is divided into A, B, C, D, E, and each category is refined depending on the nature of different substances. "Malonate class" specified in article 3.1.3 of "building design for fire protection" refers to the flammable solid.

- Q: What are the differences of ceramics and refractories? Is the ceramics belonging to refractories?

- No In the high school chemistry, the former is talking about the traditional inorganic material, the latter is belonged to the new materials.

Send your message to us

80% Round Kiln Alumina Calcined Bauxite Refractory Raw Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords